Standard diameter - Category 1

28.994 ÷ 29.000

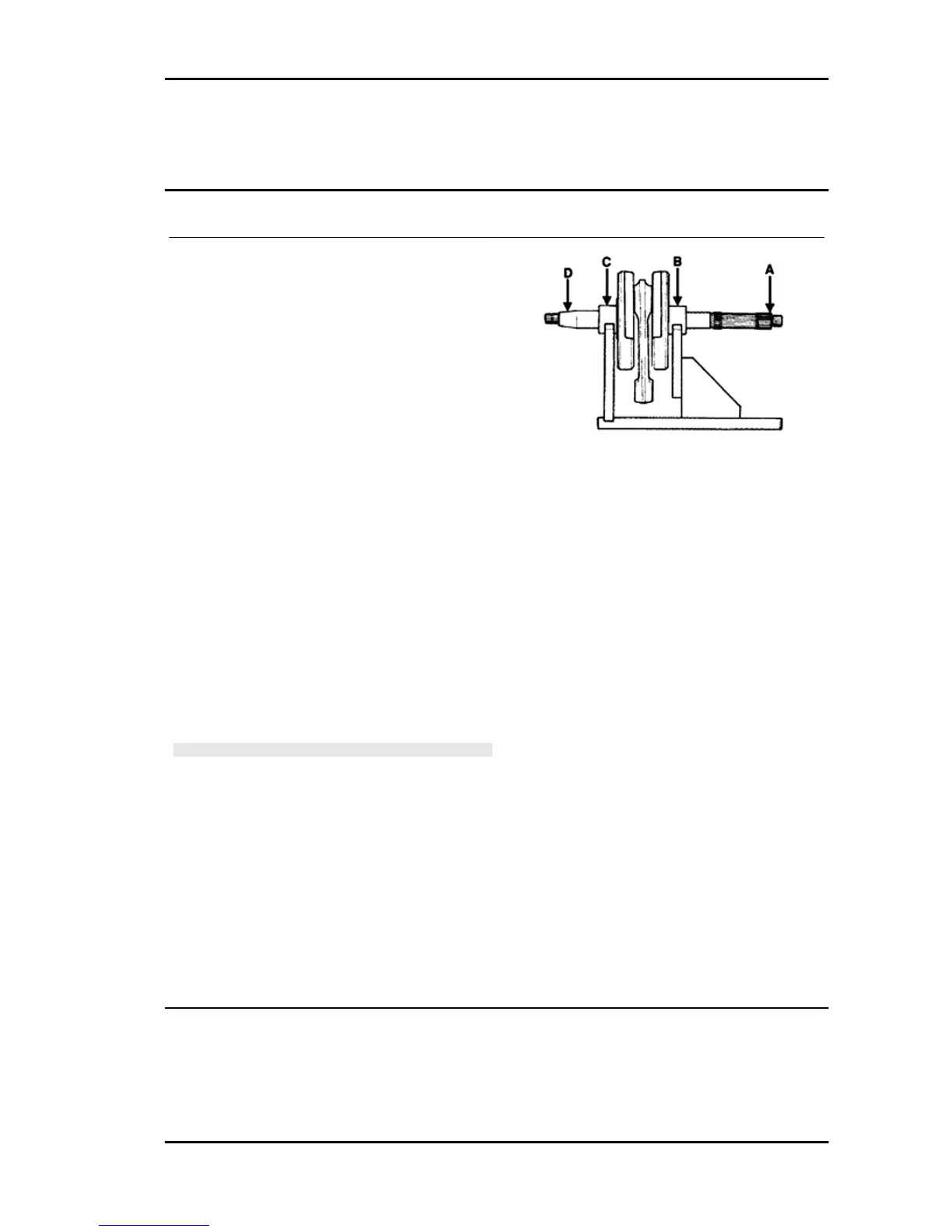

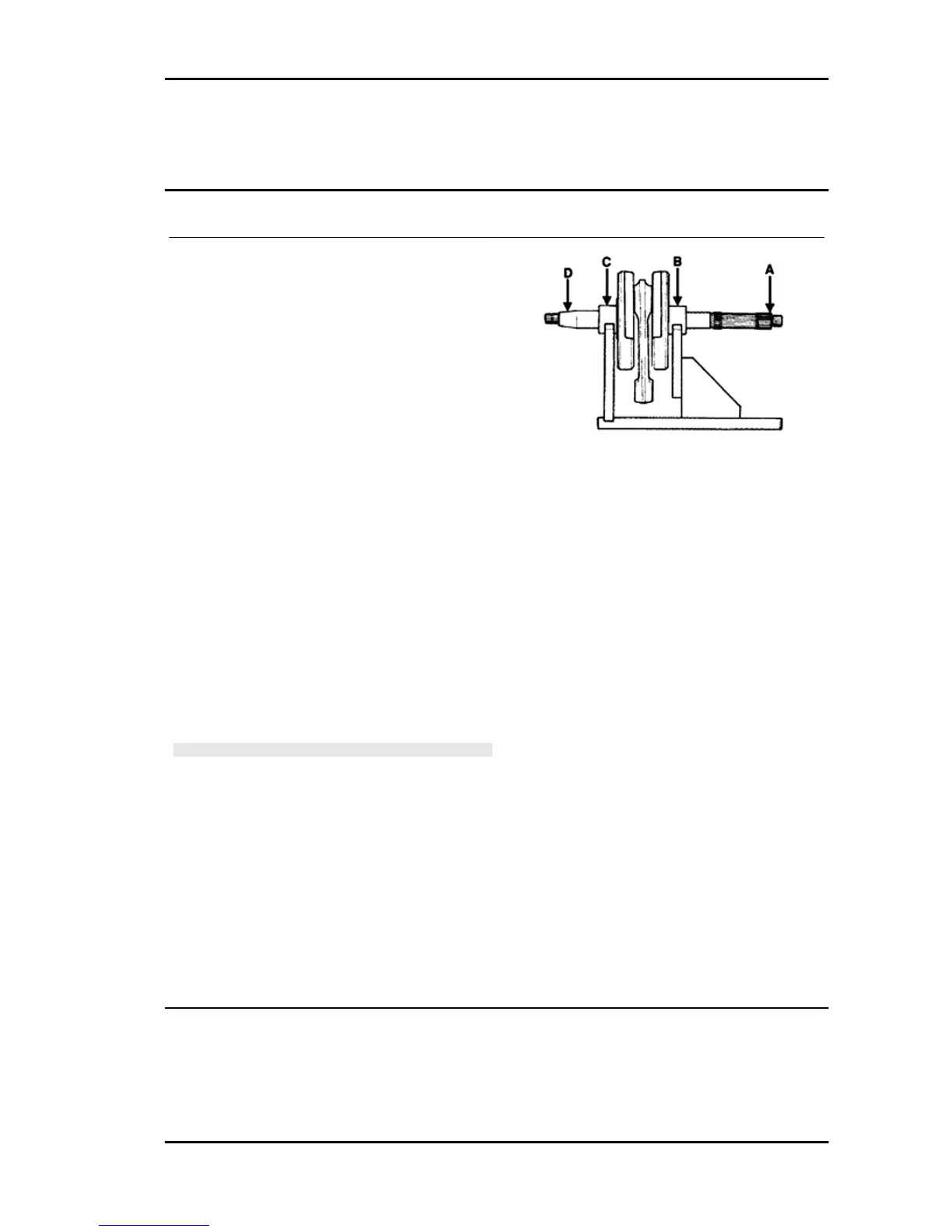

Inspecting the crankshaft alignment

To install the drive shaft on the support and to

measure the misalignment in the 4 points indicated

in figure.

- Check that the driving shaft cone, the tab seat,

the oil seal capacity, the toothed gear and the

threaded tangs are in good working order.

- In case of failures, replace the crankshaft.

The connecting rod head bushings cannot be re-

placed. For the same reason, the connecting rod

may not be replaced and, when cleaning the

crankshaft, be very careful that no impurities get in

through the shaft's lubrication holes.

In order to prevent damaging the connecting rod

bushings, do not attempt cleaning the lubrication

duct with compressed air.

- Make sure that the 2 caps on the crankpin are

properly fitted.

- A wrong installation of a cap can seriously affect

the bushing lubrication pressure.

N.B.

THE MAIN BEARINGS ARE NOT GRINDABLE

Specific tooling

020074Y Support base for checking crankshaft

alignment

Characteristic

Off-line maximum admitted

A = 0.15 mm

B = 0.01 mm

C = 0.01 mm

D = 0.10 mm

Measure the capacity of both axes X-Y

Specific tooling

020074Y Support base for checking crankshaft alignment

Runner 125 - 200 Engine

ENG - 175

Loading...

Loading...