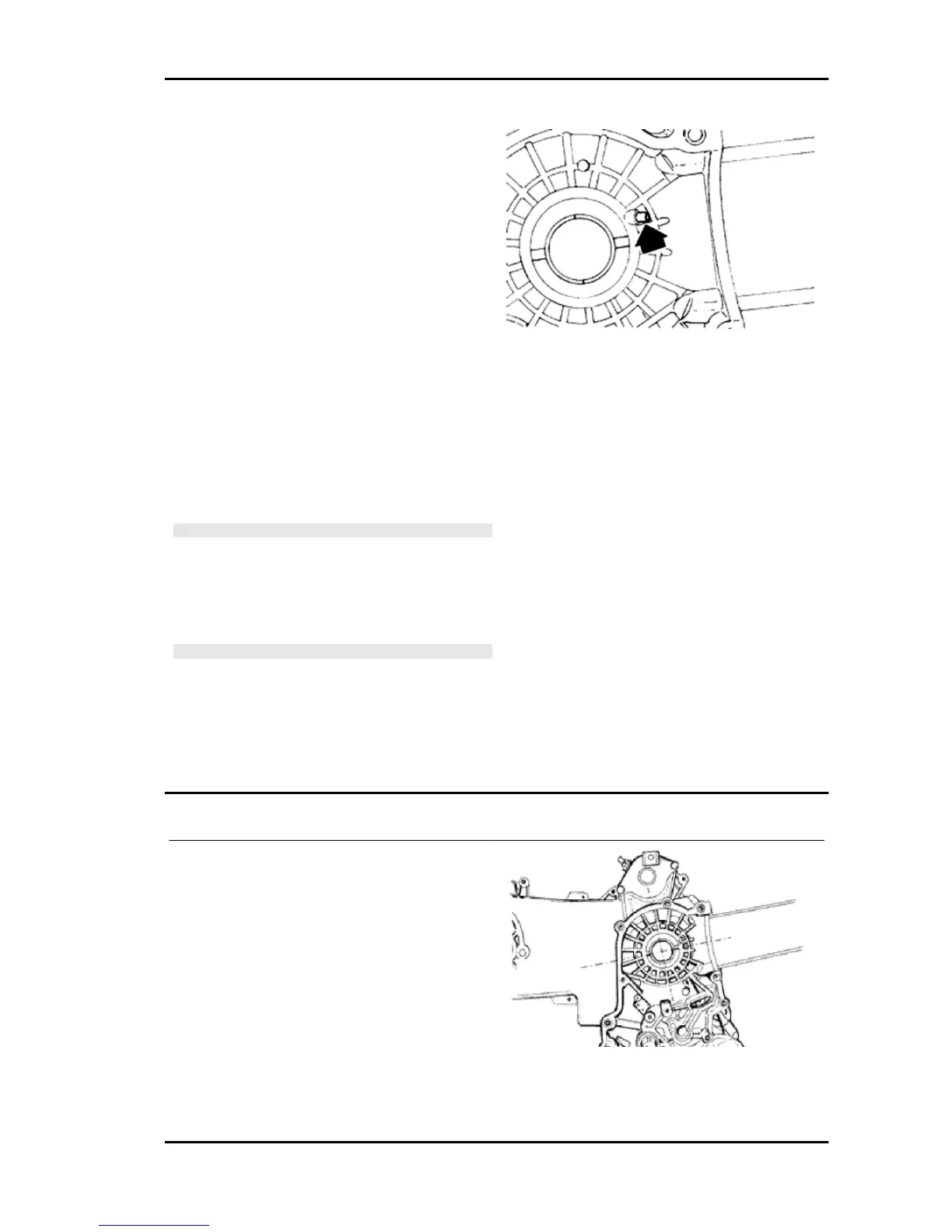

- Inspect the coupling surfaces on the crankcase

halves for scratches or deformation, taking partic-

ular care with the cylinder/crankcase surfaces and

the crankcase halves surfaces.

- Defects in the crankcase coupling gasket be-

tween the crankcase halves or the mating surfaces

shown in the diagram, could cause a drop in the

oil pressure lubricating the main bearings and con-

nection rod.

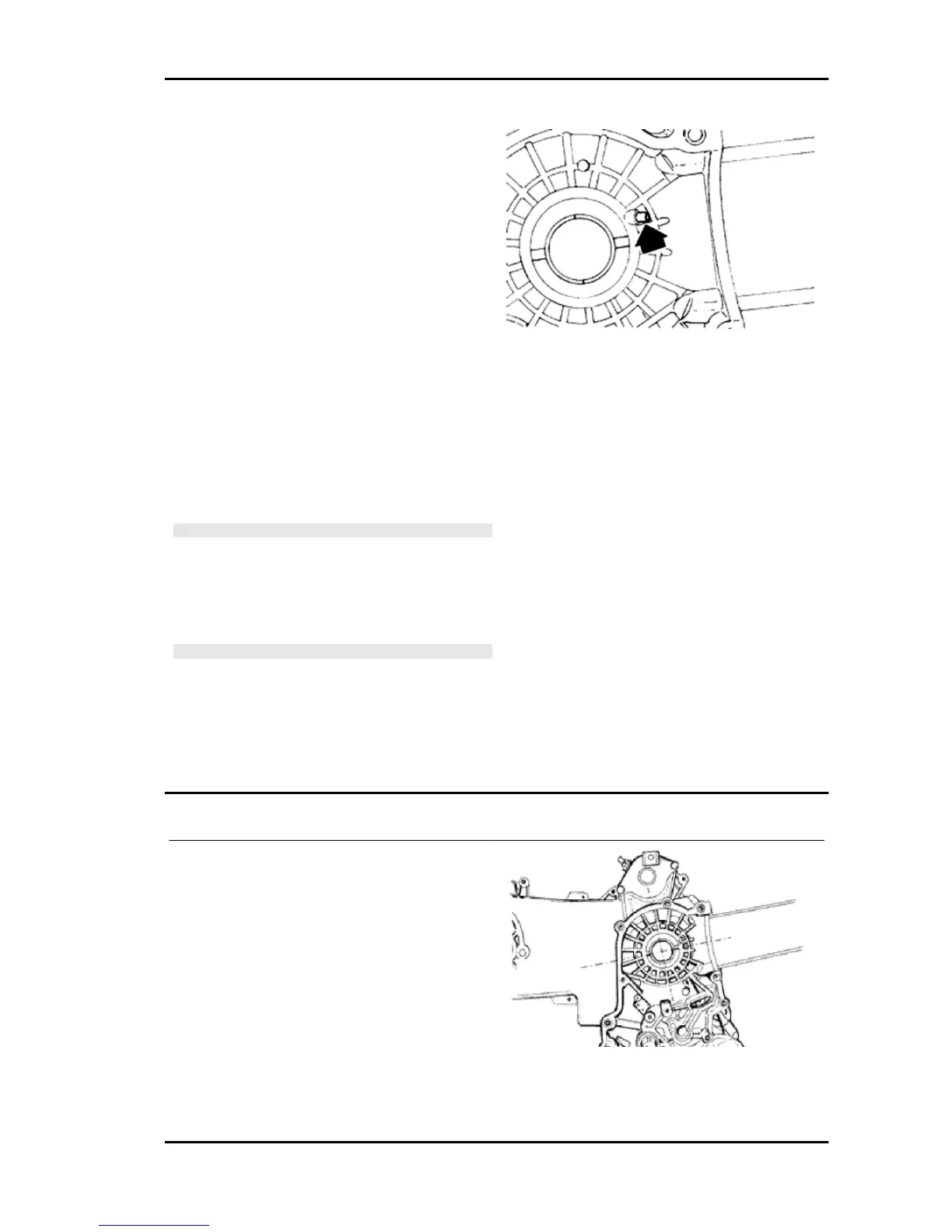

- Check the main bearing seats that limit axial

clearance in the crankshaft show no signs of wear.

The dimension between these seats is measured

by way of the procedure described previously for

measuring the crankshaft axial clearance and di-

mensions.

N.B.

THE JET IS FED THROUGH THE MAIN BUSHINGS. PROP-

ER OPERATION OF THIS COMPONENT IMPROVES THE

PISTON TOP COOLING. CLOGGING HAS EFFECTS THAT

ARE DIFFICULT TO DETECT (PISTON TEMPERATURE IN-

CREASE). FAILURE OR LEAK CAN CONSIDERABLY DE-

CREASE THE MAIN BUSHING AND CONNECTING ROD

LUBRICATION PRESSURE.

N.B.

THE HEAD LUBRICATION CHANNEL IS PROVIDED WITH

A SHUTTER JET; THIS GIVES A "LOW PRESSURE" HEAD

LUBRICATION; THIS CHOICE WAS MADE TO REDUCE

THE OIL TEMPERATURE IN THE SUMP. THE JET CLOG-

GING IMPAIRS THE HEAD LUBRICATION AND THE TIM-

ING MECHANISMS. A JET FAILURE CAUSES A DE-

CREASE OF THE MAIN BUSHING AND CONNECTING ROD

LUBRICATION PRESSURE.

Inspecting the crankshaft plain bearings

- T

o obtain a good bushing lubrication it is necessary

to have both an optimal lubricating pressure (3,2

bar) and a good oil flow rate; the bushings must be

correctly positioned so as not to obstruct the oil

supply channels.

- The main bushings are comprised of two half-

bearings, one with holes and channels for lubrica-

tion whereas the other is solid.

Runner 125 - 200 Engine

ENG - 177

Loading...

Loading...