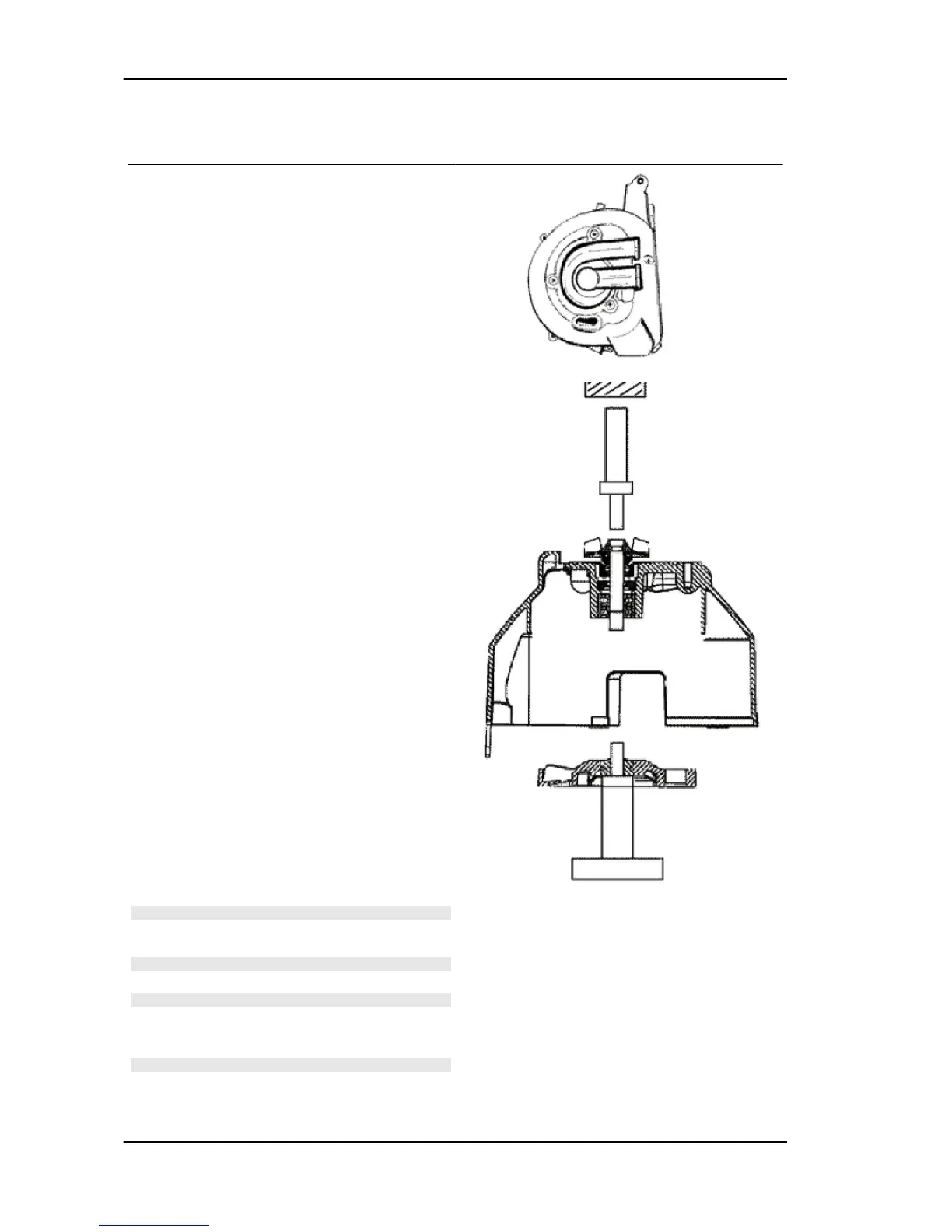

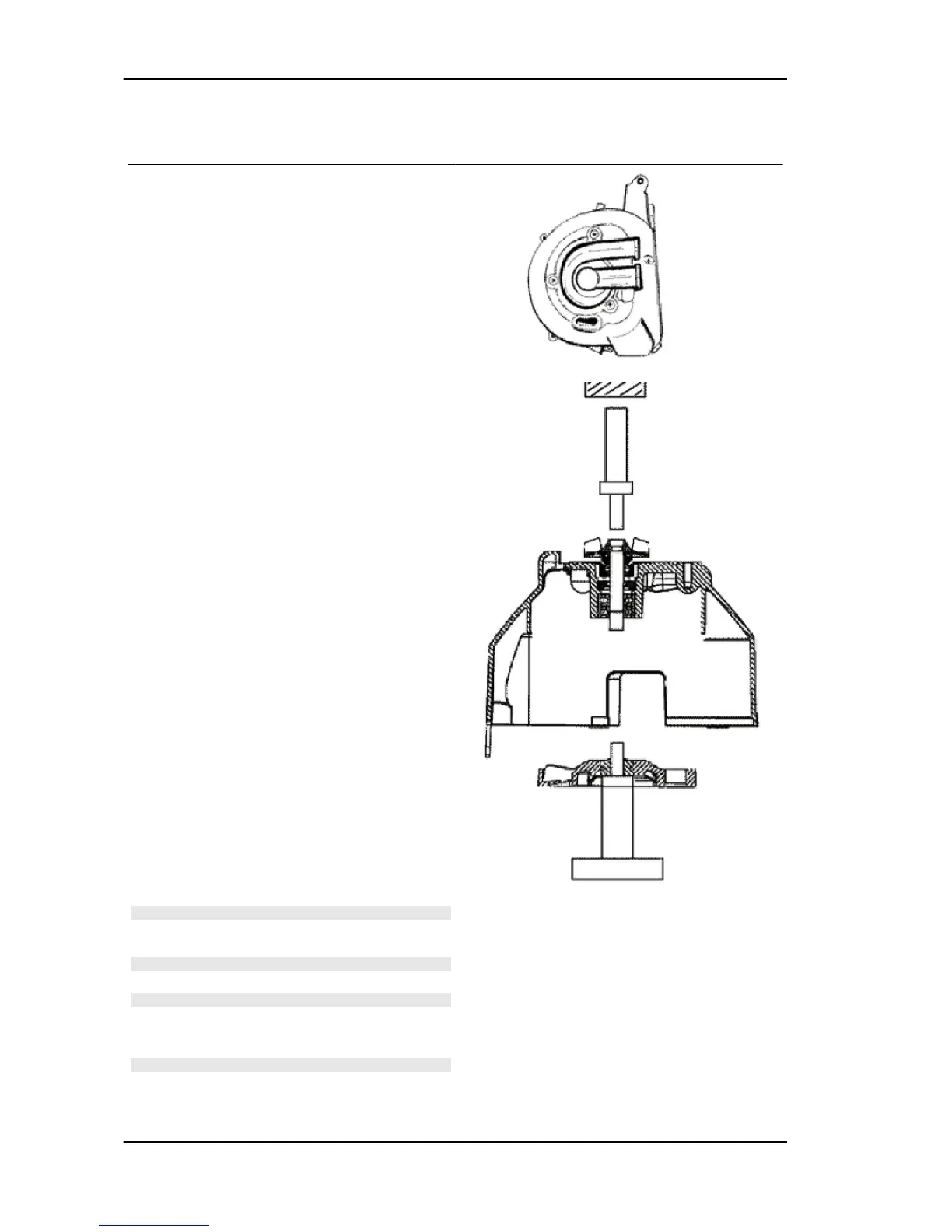

Water pump - overhaul

With a hot air gun heat the flywheel cover on the

inner side.

- Place the flywheel cover on the ring base follow-

ing the same procedure as for removal.

- Place the two bearings on the specific punch.

- Use grease to keep the bearings on the appro-

priate tool.

- Use a plastic mallet to insert the bearings on the

housing up to the stop.

- Assembly the ceramic ring and the correspond-

ing rubber gasket. The ceramic ring chamfering

should always face towards the gasket.

- Lubricate the rubber gasket and insert the unit on

the flywheel cover.

Use the punch of the appropriate tool manually if

necessary.

Insert the drive on the guide on the support base

facing part of the appropriate tool, being careful to

check that the convex part faces upwards.

- Insert the flywheel cover with bearings on the ap-

propriate tool.

- Insert the shaft together with the mechanical gas-

kets on the bearings.

- With the appropriate punch and socket, insert the

shaft in the bearings and the drive until the end of

stroke of the appropriate tool cannot be seen.

- Reassemble the rotor cover with a new O-Ring.

- Tighten the 3 fixing screws to the torque below.

N.B.

AVOID OVERHEATING AS THIS MAY ALTER THE PAIN-

TED SURFACE.

N.B.

ALWAYS USE NEW BEARINGS.

N.B.

ALWAYS USE NEW CERAMIC RING AND GASKETS. AS-

SEMBLING THE CERAMIC SEALING RING IN A MANNER

OTHER THAN MANUALLY MAY DAMAGE THE RING.

N.B.

Centre the punch well on the rotor. Push the shaft in and check

that the wheel flywheel cover is level. Failure to respect this

procedure damages the drive.

Cooling system Runner 125 - 200

COOL SYS - 260

Loading...

Loading...