such cases we recommend cleaning the casing in order to be able to check again for leaks after a

distance of more than 1500 km. If leaks continue or in the event of real losses, the ceramic seal should

be replaced. For these operations, observe the tools and instructions given in the relevant service

station manuals.

Note: The ceramic seal may be overhauled according to the following couplings:

•

Coupling "A": seal ring no. 485084 with ceramic seal no. 486216

•

Coupling "B": seal ring no. 841329 with ceramic seal no. 841330

The couplings above may be selected according to their availability, as they are interchangeable.

- Check the water pump if noise in the bearings or

liquid leaking from the drainage hole inside the

cover is detected.

- Remove the flywheel cover together with the wa-

ter pump from the engine (see chapter 4).

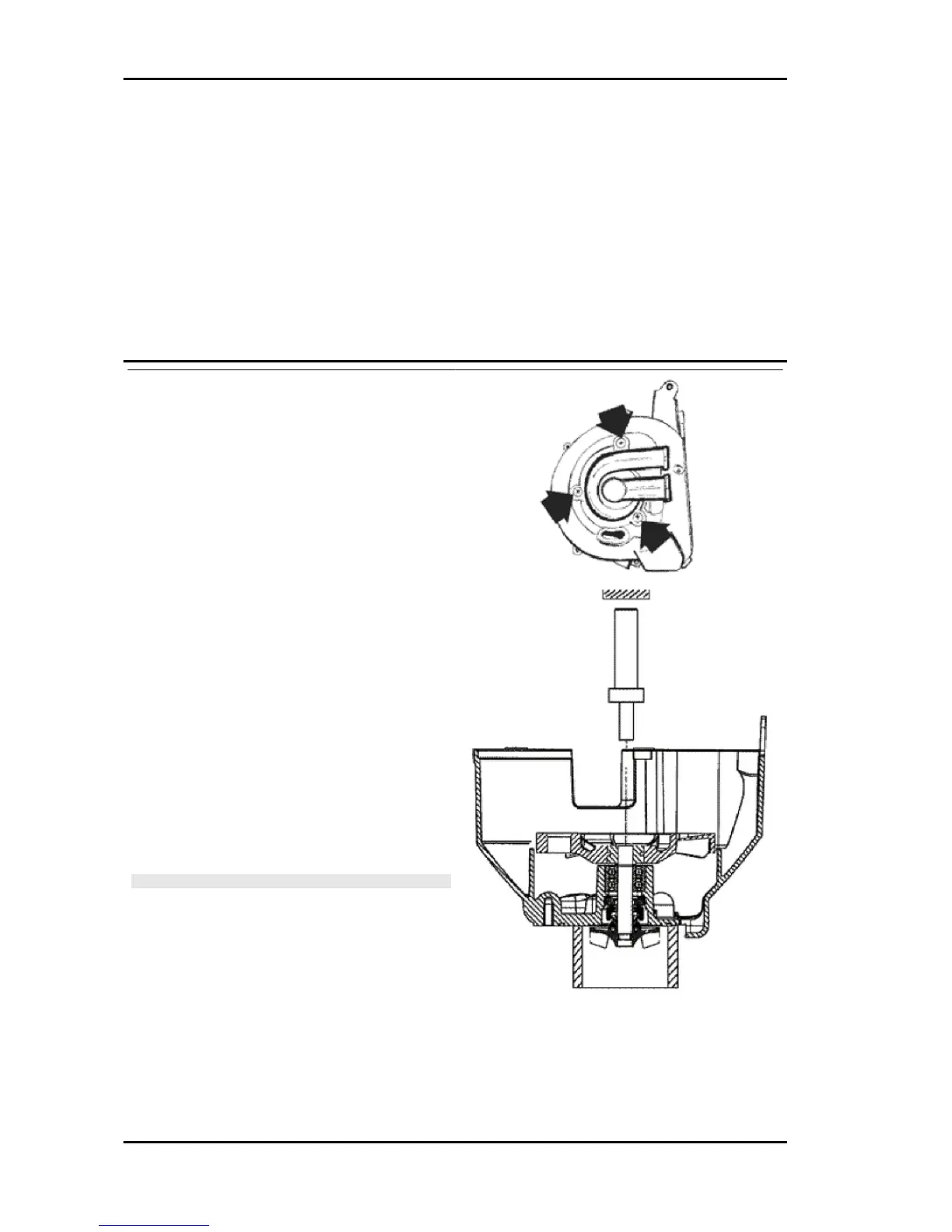

- Remove the rotor cover by unscrewing the 3 re-

tainers indicated in the figure.

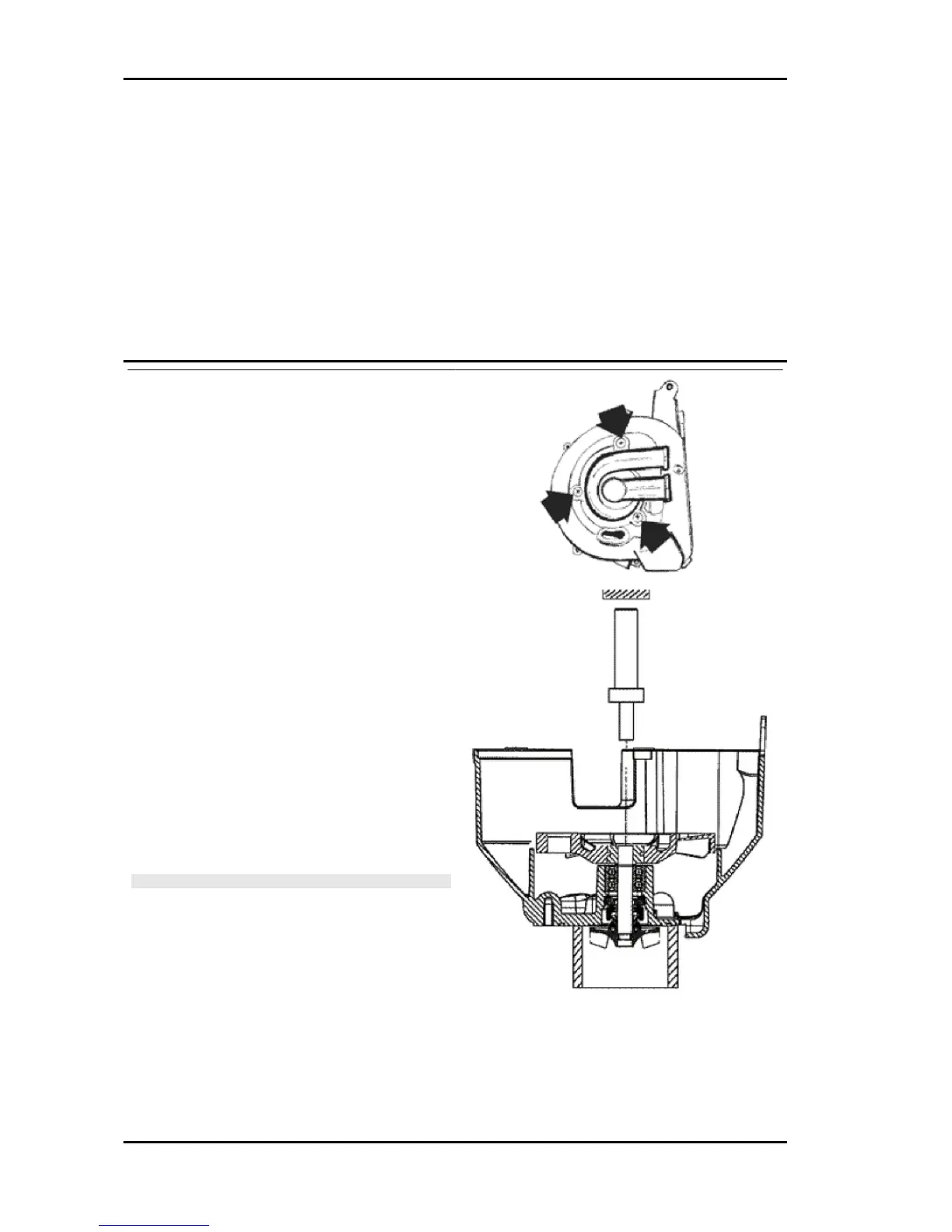

- Place the flywheel cover on the ring base forming

part of the tool drawing No 020440Y

With an appropriate socket and punch, forming

part of the specific tool 020440y, extract the shaft

together with the rotor from the drive and the bear-

ings.

- Use a screwdriver to remove the static part of the

ceramic seal from the flywheel cover.

- Place the flywheel cover below the socket making

sure it is perfectly levelled.

- Use the punch in the inverted position to extract

the two ball bearings.

N.B.

To avoid damaging the cover surface that retains the coolant,

use de ring base with the accurately machined surface facing

the flywheel cover.

Specific tooling

020440Y Water pump service tool

Cooling system Runner 125 - 200

COOL SYS - 262

Loading...

Loading...