*PIPER

CHEROKEE

SIX

SERVICE

MANUAL

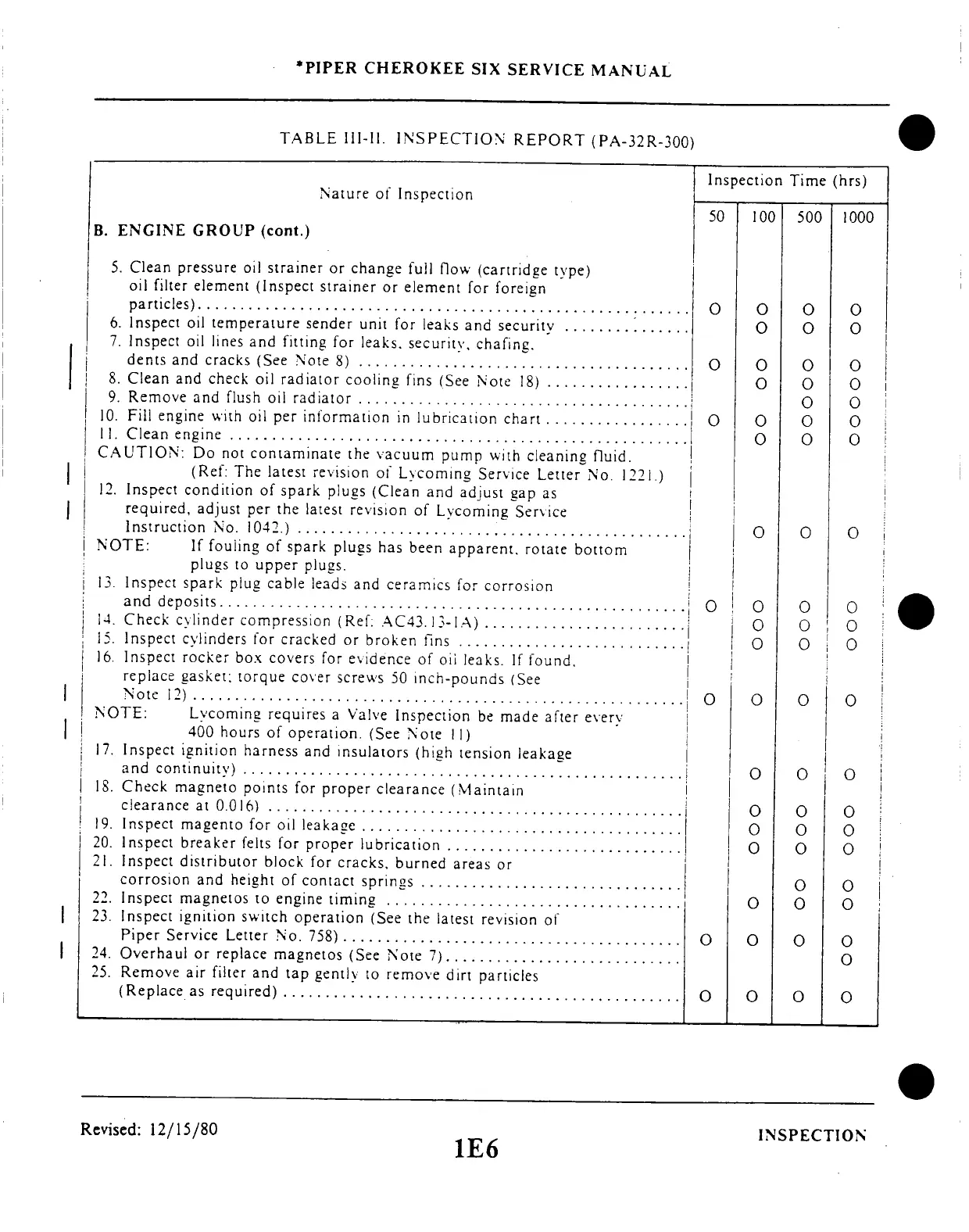

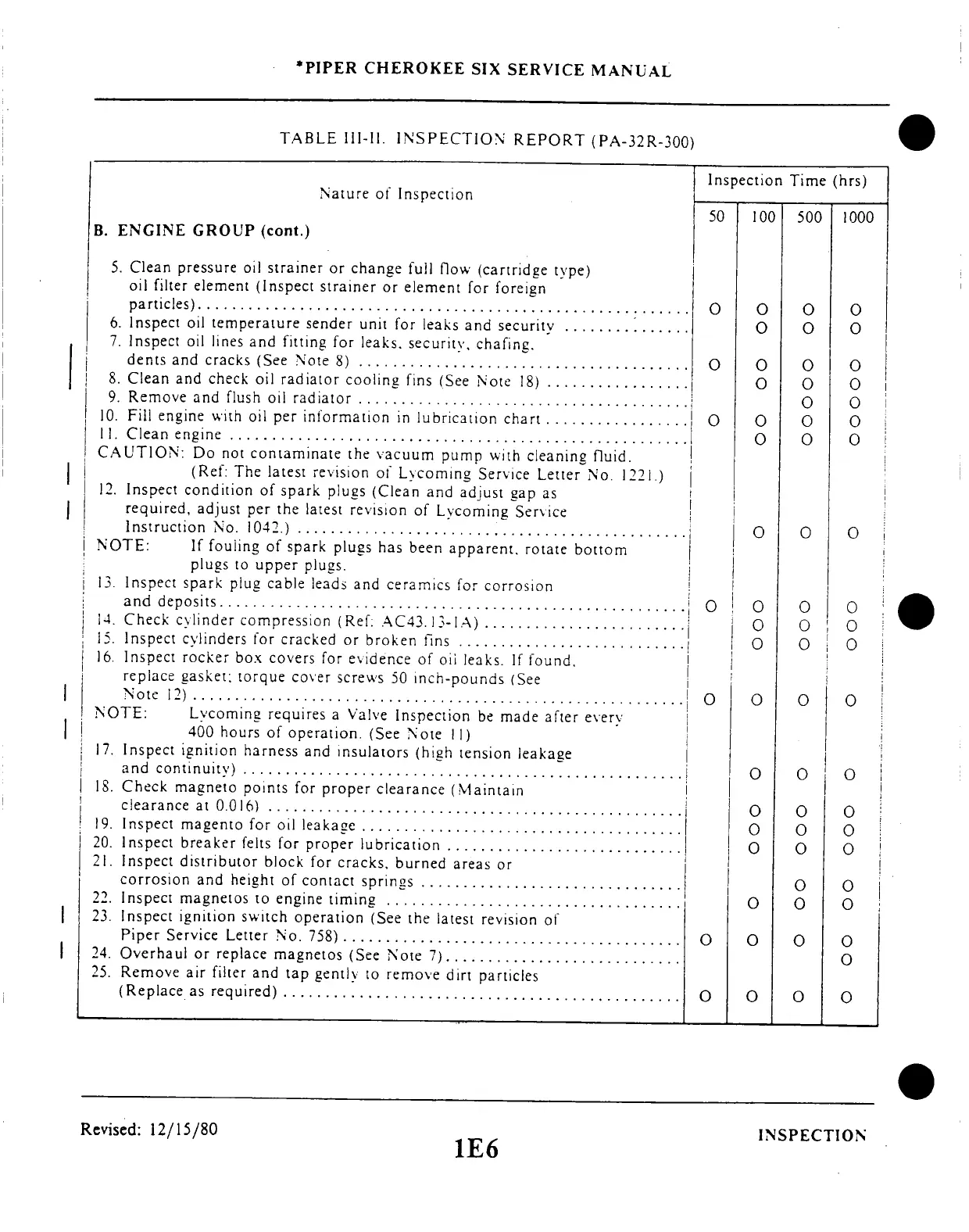

TABLE

11-11.

INSPECTION

REPORT

(PA-32R-300)

Inspection

Time

(hrs)

I

I

I

I

Nature

of

Inspection

B.

ENGINE

GROUP

(cont.)

5.

Clean

pressure

oil

strainer

or change

full

flow

(cartridge

type)

oil

filter

element

(Inspect

strainer

or

element

for foreign

particles)

.........................................................

6.

Inspect

oil temperature

sender

unit

for

leaks

and

security

..............

7. Inspect

oil

lines

and

fitting

for

leaks.

security,

chafing.

dents

and

cracks

(See

Note

8)

......................................

8. Clean

and

check

oil

radiator

cooling

fins

(See

Note

18) ................

9.

Remove

and

flush

oil radiator

......................................

10.

Fill

engine

with

oil

per

information

in

lubrication

chart

.................

I 1.

Clean

engine

.....................................................

CAUTION:

Do

not

contaminate

the

vacuum

pump

with

cleaning

fluid.

(Ref:

The

latest

revision

of

Lycoming

Service

Letter

No.

1221.)

12.

Inspect

condition

of spark

plugs

(Clean

and

adjust

gap

as

required,

adjust

per

the

latest

revision

of Lvcoming

Service

Instruction

No.

1042.)

..........................................

NOTE:

If fouling

of

spark

plugs

has

been

apparent.

rotate

bottom

plugs

to

upper

plugs.

13. Inspect

spark

plug cable

leads

and ceramics

for

corrosion

and

deposits

....................................................

14.

Check

cylinder

compression

(Ref.

AC43.13-1A)

........................

15.

Inspect

cylinders

for

cracked

or

broken

fins

...........................

16.

Inspect

rocker

box

covers

for evidence

of

oii leaks.

If

found,

replace

gasket:

torque

cover

screws

50

inch-pounds

(See

N o

te

12)

.. .

.....

.

. .

. . ....

. . .

..

. ..

. . .

. ..

..

. . ..

..

. .

. . ..

. ...

. . ..

.

.

NOTE:

Lycoming

requires a

Valve Inspection

be

made after

every

O

O

O

O

0

0

n

50

0

0

0

0

100

500

1000

I

400

hours

of

operation.

(See

Note

II)

17.

Inspect

ignition

harness

and

insulators

(high

tension

leakage

and

continuity)

.........................

.

IS.

Check

magneto

points

for

proper

clearance

(Maintain

clearance

at 0.016)

.....................................

.....

19.

Inspect

magento

for

oil leakae

..............................

20.

Inspect

breaker

felts

for

proper

lubrication

............................

21.

Inspect

distributor

block

for

cracks,

burned

areas

or

corrosion

and

height

of contact

springs

...............................

22.

Inspect

magnetos

to

engine

timing

.........

..

...............

..

23.

Inspect

ignition

switch

operation

(See

the

latest

revision

of

Piper

Service

Letter

No.

758)

........................................

24.

Overhaul

or

replace

magnetos

(See

Note

7)...........................

25.

Remove

air

filter

and

tap

gently

to

remove

dirt

particles

(Replace

as

required)

...............................................

i

i

0

0

0

0

0

0

0 0

0

0

0

O

0

0

0

0

0

0

0

0

0 0 0

0

0

0

0

0 0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

INSPECTION

0

0

Revised:

12/15/80

1E6

Loading...

Loading...