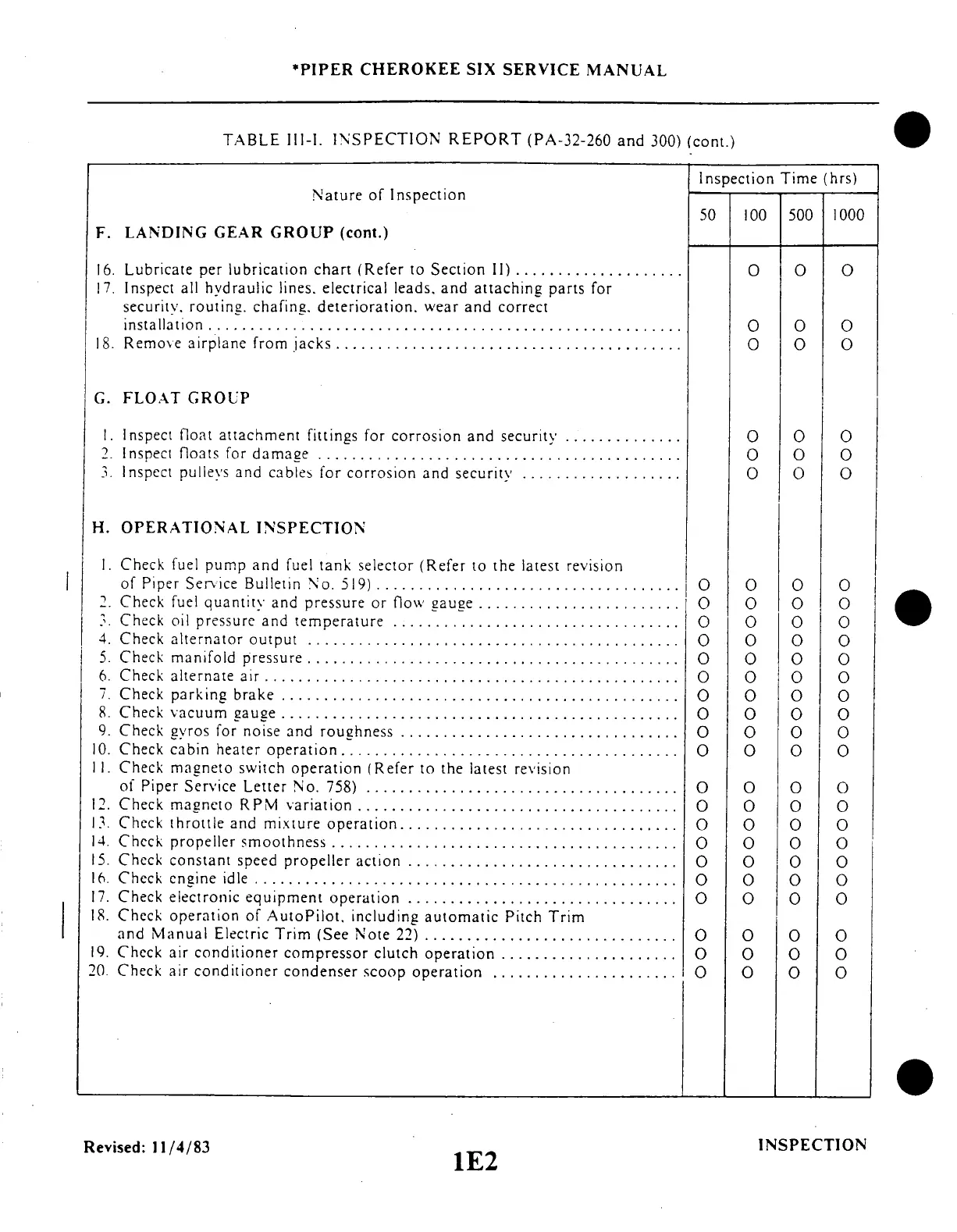

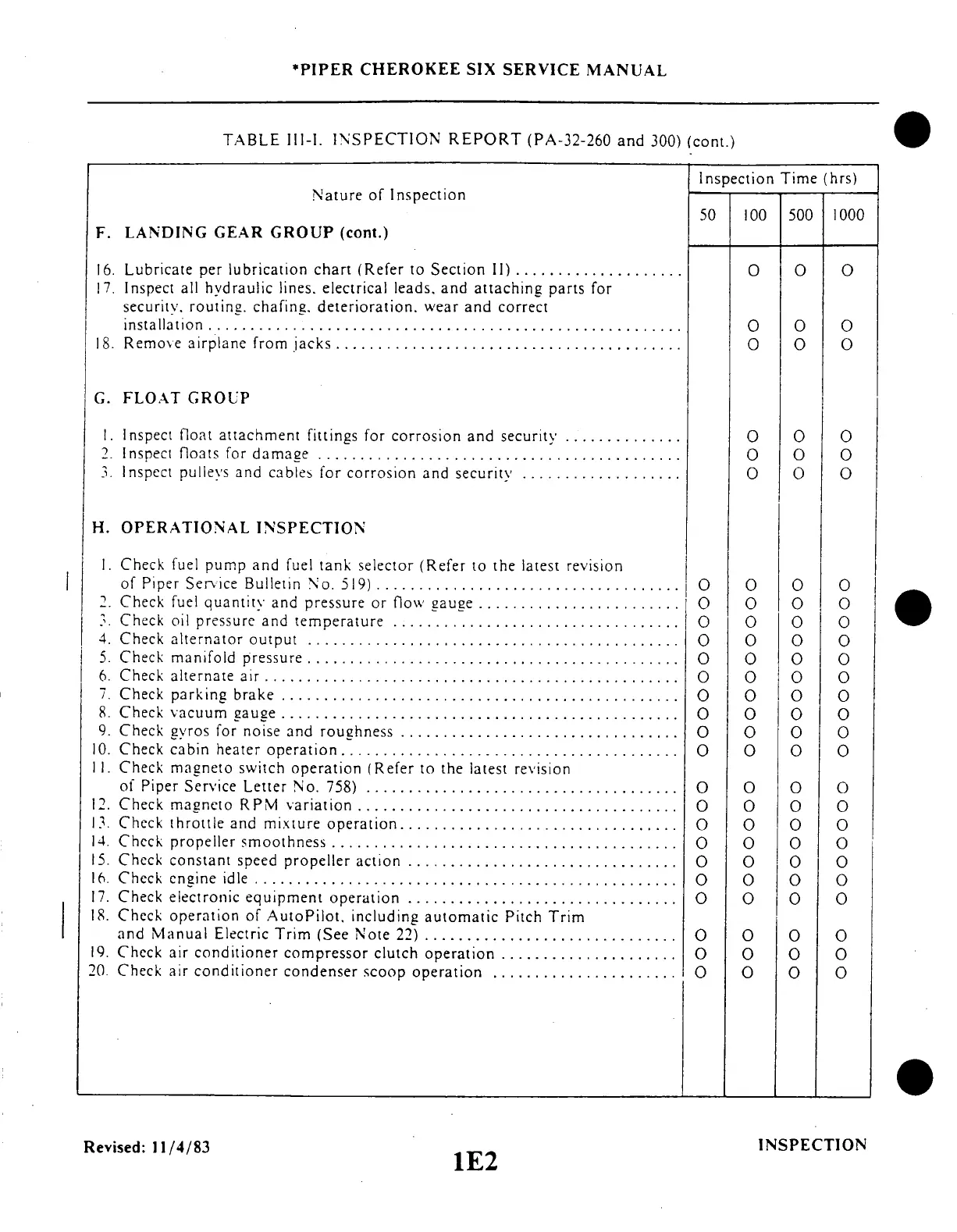

1. Inspect float

attachment

fittings for corrosion

and security

..............

2. Inspect floats

for damage

...........................................

3. Inspect

pulleys

and cables

for corrosion

and security

...................

H.

OPERATIONAL

INSPECTION

*PIPER

CHEROKEE

SIX

SERVICE

MANUAL

TABLE

III-I.

INSPECTION

REPORT

(PA-32-260

and 300)

(cont.)

Inspection

Time

(hrs)

Nature of Inspection

50 100 500 1000

F. LANDING GEAR GROUP (cont.)

16.

Lubricate per lubrication chart (Refer

to Section II) ....................

17. Inspect all

hydraulic lines,

electrical leads,

and attaching

parts for

security,

routing, chafing, deterioration.

wear and correct

installation

.......................................................

18. Remove airplane from

jacks .........................................

O O O

O O O

O O O

G. FLOAT GROUP

1. Check

fuel pump

and fuel

tank selector

(Refer

to the

latest revision

of Piper

Service Bulletin

No.

519) ....................................

2.

Check fuel

quantity

and pressure

or flow

gauge ........................

3. Check

oil pressure

and temperature

..................................

4. Check

alternator

output

............................................

5. Check

manifold pressure

..........................................

6. Check

alternate

air................................................

7. Check

parking brake

...............................................

8.

Check vacuum

gauge

...........

............................

9. Check

gyros for noise

and roughness

.................................

10. Check

cabin heater

operation

........................................

II. Check

magneto

switch

operation

(Refer

to the

latest revision

of Piper

Service Letter

No. 758)

.....................................

12.

Check magneto

RPM variation

.....................................

13. Check

throttle and mixture

operation

................................

14. Check propeller

smoothness

.........................................

15.

Check constant

speed

propeller action

................................

16. Check engine

idle ..................................................

17. Check

electronic

equipment

operation

................................

18. Check

operation

of AutoPilot.

including

automatic

Pitch Trim

and

Manual

Electric Trim

(See Note

22) ..............................

19. Check

air conditioner

compressor

clutch operation

.....................

20. Check

air conditioner

condenser scoop

operation ......................

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

O 0 0

O

0

0

0 0 0

0 0 0

O 0 0

0 0

O

0

0

0 0 0

0 O 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

0 0 0

Revised: 11/4/83

INSPECTION

1E2

Loading...

Loading...