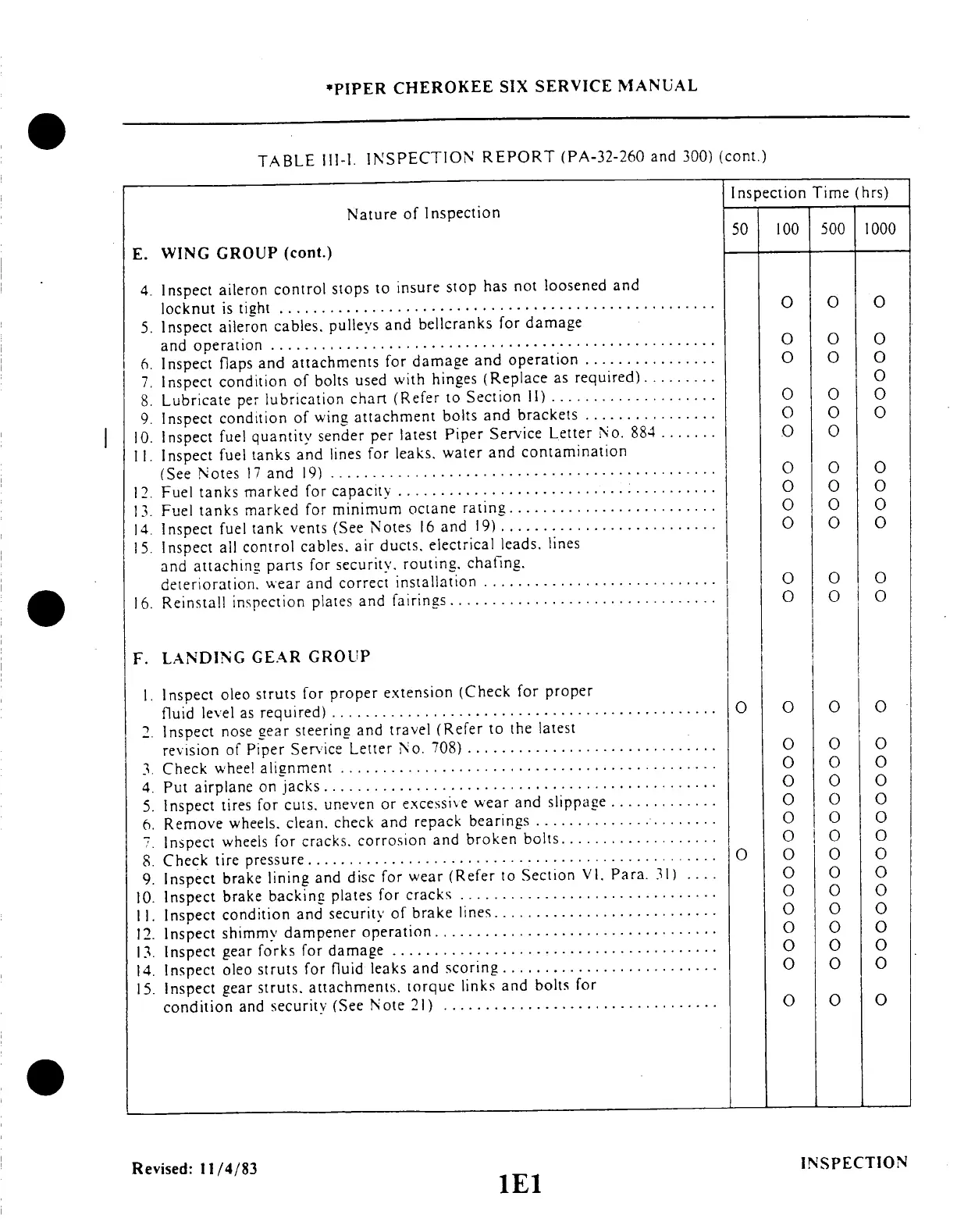

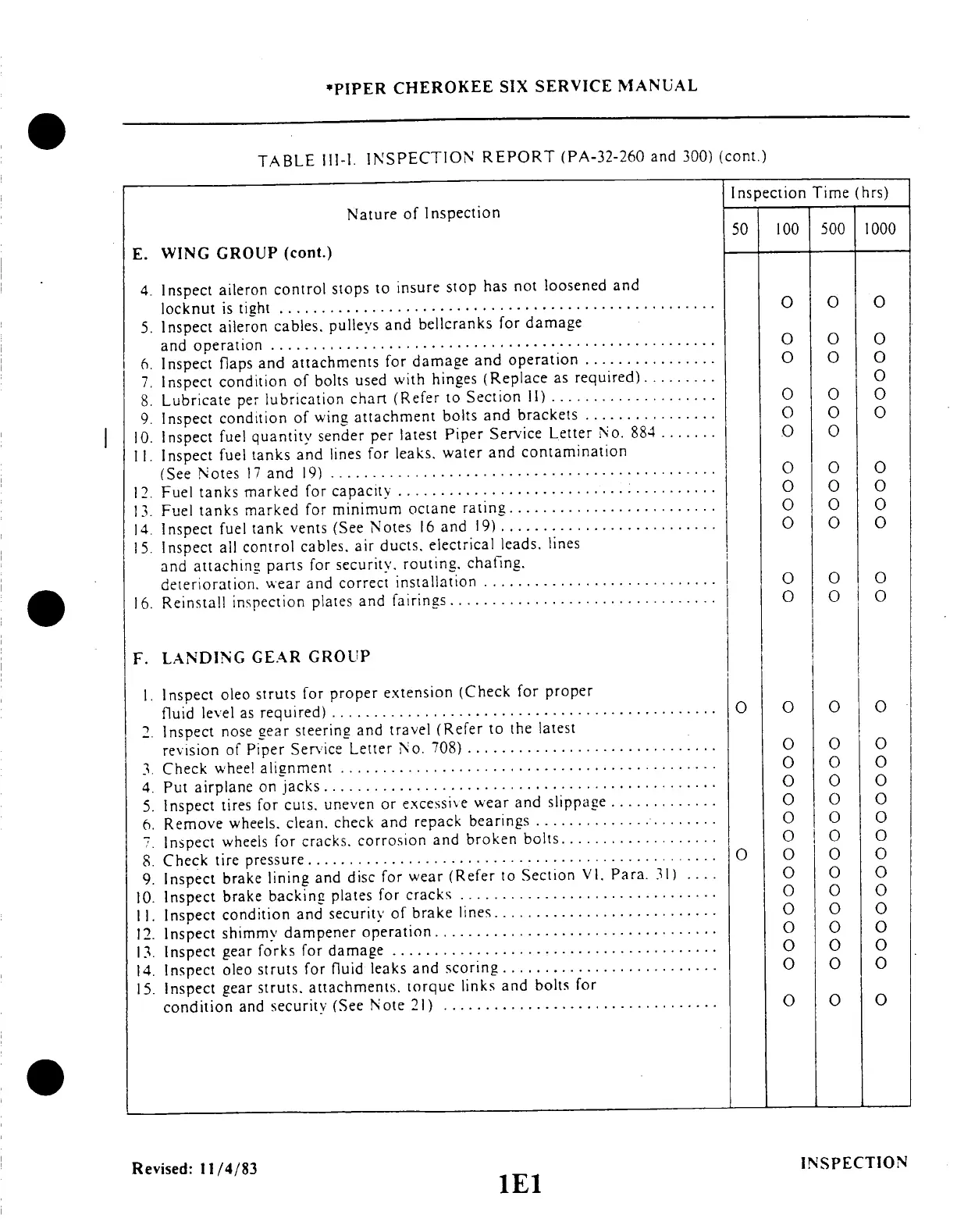

4.

Inspect

aileron

control

stops

to

insure

stop

has

not

loosened

and

locknut

is

tight

....................................................

5.

Inspect

aileron

cables.

pulleys

and

bellcranks

for

damage

and

operation

.....................................................

6.

Inspect

flaps

and

attachments

for

damage

and

operation

................

7.

Inspect

condition

of

bolts

used

with

hinges

(Replace

as

required).........

8.

Lubricate

per

lubrication

chart

(Refer

to

Section

II)

....................

9.

Inspect

condition

of

wing

attachment

bolts

and

brackets

................

10.

Inspect

fuel

quantity

sender

per

latest

Piper

Service

Letter

No.

884.......

II.

Inspect

fuel

tanks

and

lines

for

leaks.

water

and

contamination

(See

Notes

17

and

19)

..............................................

12.

Fuel

tanks

marked

for

capacity

.....................................

13.

Fuel

tanks

marked

for

minimum

octane

rating

........................

14.

Inspect

fuel

tank

vents

(See

Notes

16

and

19)

..........................

15.

Inspect

all

control

cables.

air

ducts.

electrical

leads.

lines

and

attaching

parts

for

security,

routing.

chafing.

deterioration.

wear

and

correct

installation

............................

16.

Reinstall

inspection

plates

and

fairings

................................

*PIPER

CHEROKEE

SIX

SERVICE

MANUAL

TABLE

111-1.

INSPECTION

REPORT

(PA-32-260

and

300)

(cont.)

Inspection

Time

(hrs)

Nature

of

Inspection

50

100

500

1000

E.

WING

GROUP

(cont.)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

F.

LANDING

GEAR

GROUP

0

0

1.

Inspect

oleo

struts

for

proper

extension

(Check

for

proper

fluid

level

as

required)

..................................

2.

Inspect

nose

gear

steering

and

travel

(Refer

to

the

latest

revision

of

Piper

Service

Letter

No.

708)

..................

3.

Check

wheel

alignment

.................................

4.

Put

airplane

on

jacks

...................................

5.

Inspect

tires

for

cuts,

uneven

or

excessive

wear

and

slippage

.

6.

Remove

wheels.

clean.

check

and

repack

bearings

..........

7.Inspect

wheels

for

cracks.

corrosion

and

broken

bolts.......

8.

Check

tire

pressure

.....................................

9.

Inspect

brake

lining

and

disc

for

wear

(Refer

to

Section

VI.

F

10.

Inspect

brake

backing

plates

for

cracks

...................

I

I.

Inspect

condition

and

security

of

brake

lines

...............

12.

Inspect

shimmy

dampener

operation

......................

13.

Inspect

gear

forks

for

damage

...........................

14.

Inspect

oleo

struts

for

fluid

leaks

and

scoring

..............

15.

Inspect

gear

struts.

attachments.

torque

links

and

bolts

for

condition

and

security

(See

Note

21)

.....................

Revised:

11/4/83

1E1

o

o

0 0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 0 0

Para.

31)

....

O

O

O

INSPECTION

Loading...

Loading...