3.60

ENGINE

2. Lightly tighten all fasteners evenly to eliminate any gaps

that may be present in the mounting areas.

3. Torque fasteners to specification using a 2 part sequence.

• Torque fasteners to half of the specified torque value

• Then torque fasteners to the full specified torque value

Install drive clutch, driven clutch, and belt. Torque to

specification (see Chapter 6).

• Clean clutch sheaves thoroughly and inspect inlet and

outlet ducts for proper routing and sealing.

To install engine assembly, reverse the “Engine Removal”

procedure detailed earlier in this Chapter.

• Properly route all electrical harnesses for engine

assembly installation. Check for any possible rubbing

points of electrical wires.

• Carefully set the engine assembly into the vehicle while

installing the propshaft.

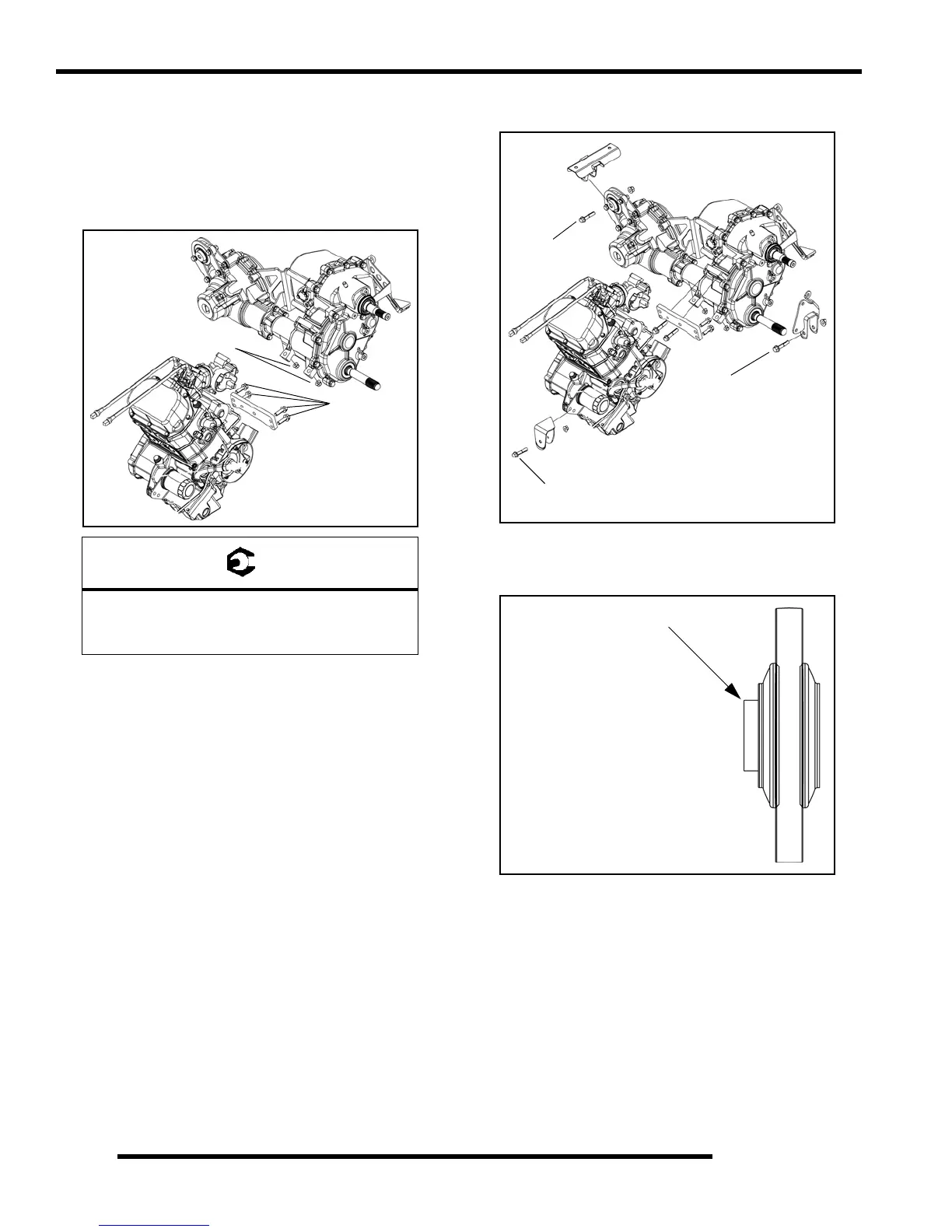

• Install engine / transmission / rear gearcase mounting

hardware and torque to specification.

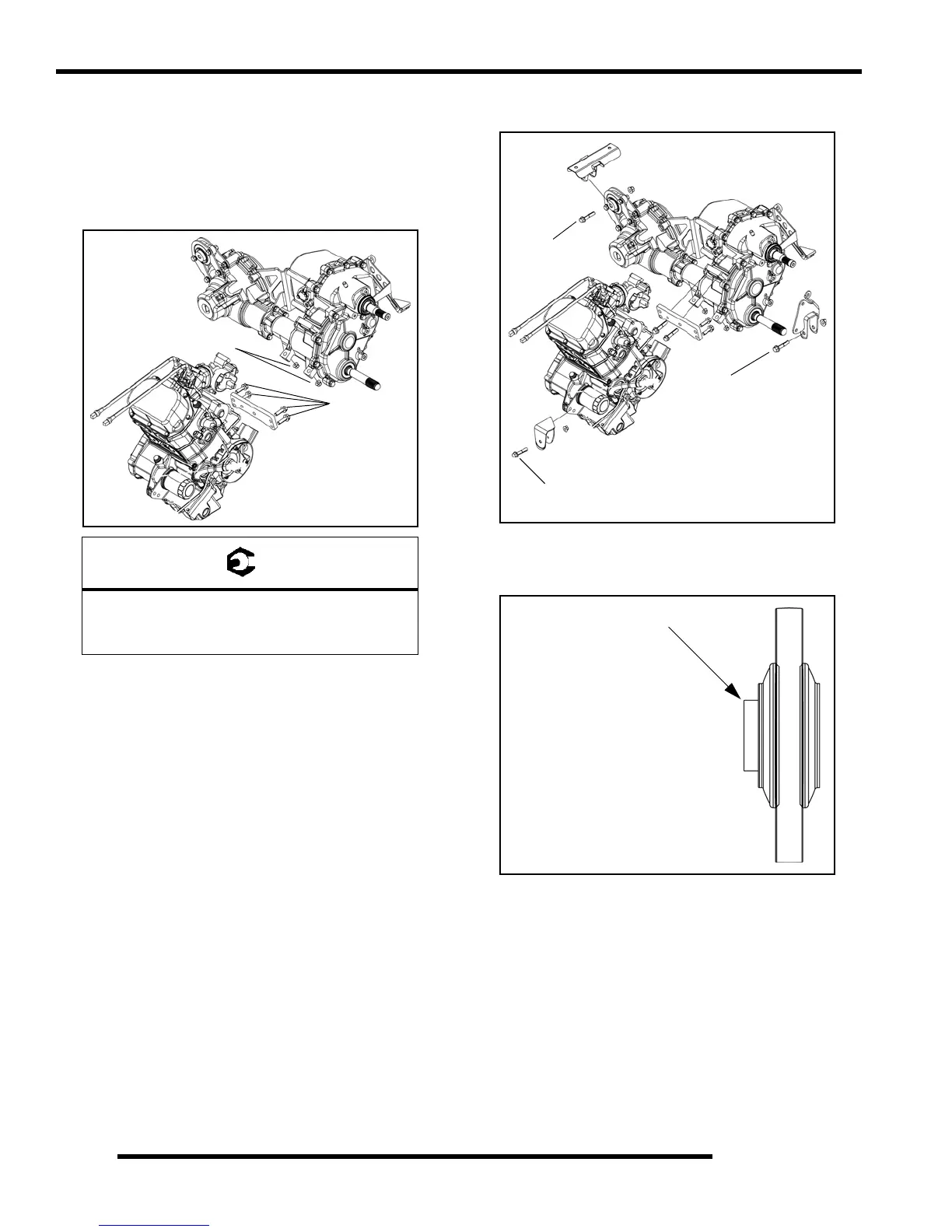

NOTE: If isolator mounts were removed or replaced,

use the following illustration to ensure proper

orientation during installation.

• Replace exhaust gaskets. Seal connections with high

temp silicone sealant. Check to be sure all exhaust

springs are in good condition.

• Inspect transmission operation and adjust linkage if

necessary (see Chapter 2 “Shift Linkage Adjustment”).

• Checks fluid levels: engine oil, transmission lubricant,

and rear gearcase lubricant.

• Bleed cooling system as described in this Chapter under

“Cooling System Bleeding Procedure.”

= T

Engine / Transmission Mounting Fasteners

(2) Lower 3/8” Nuts: 40 ft. lbs. (54 Nm)

(4) Outer M8 Bolts: 28 ft. lbs. (38 Nm)

40 ft. lbs.

(54 Nm)

28 ft. lbs.

(38 Nm)

17 ft. lbs.

(23 Nm)

17 ft. lbs.

(23 Nm)

30 ft. lbs.

(41 Nm)

The protrusion of the mount

must face inward towards

the engine.

The protrusion of the mount

must face the RH side of

the vehicle.

Front Isolator Mounts

Rear Isolator Mounts

Mount Protrusion

Loading...

Loading...