6.8

CLUTCHING

Belt Inspection

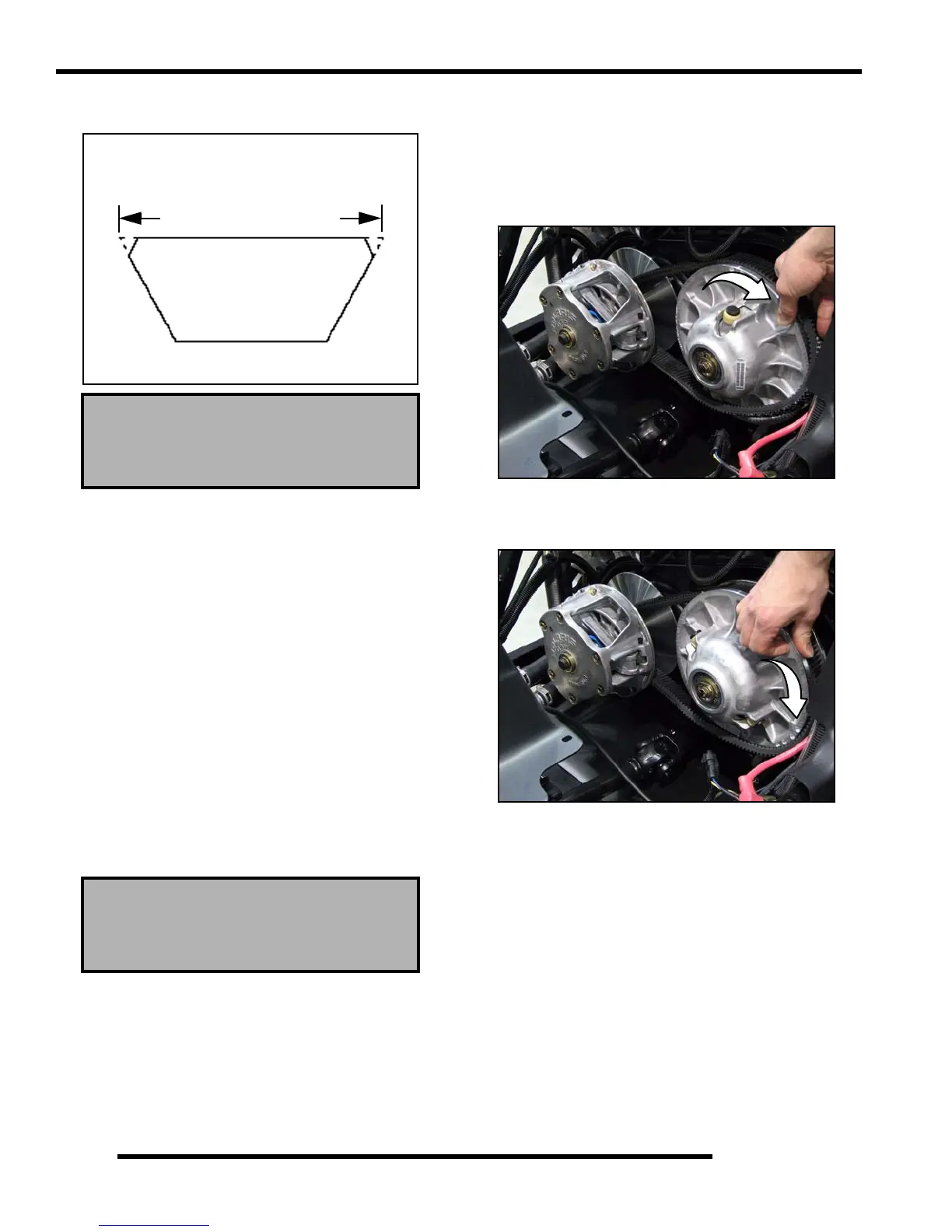

1. Measure belt width and replace if worn severely.

• The top edges have been trimmed on some drive belts.

It will be necessary to project the side profiles and

measure from corner to corner.

• Place a straight edge on each side of the drive belt.

• Place another straight edge on top of belt.

• Measure the distance where the side straight edges

intersect the top.

2. Inspect belt for loose cords, missing cogs, cracks,

abrasions, thin spots, or excessive wear. Replace if

necessary.

3. Inspect belt for hour glassing (extreme circular wear in at

least one spot and on both sides of the belt). Hour glassing

occurs when the drive train does not move and the drive

clutch engages the belt.

4. Measure belt length with a tape measure around the outer

circumference of the belt.

5. Replace belt if worn past the wear limit. Belts with thin

spots, burn marks, etc., should be replaced to eliminate

noise, vibration, or erratic PVT operation. See the

Troubleshooting Chart at the end of this chapter for

possible causes.

Belt Installation

NOTE: Be sure to position belt in the same position

as when removed or so part number is easily read.

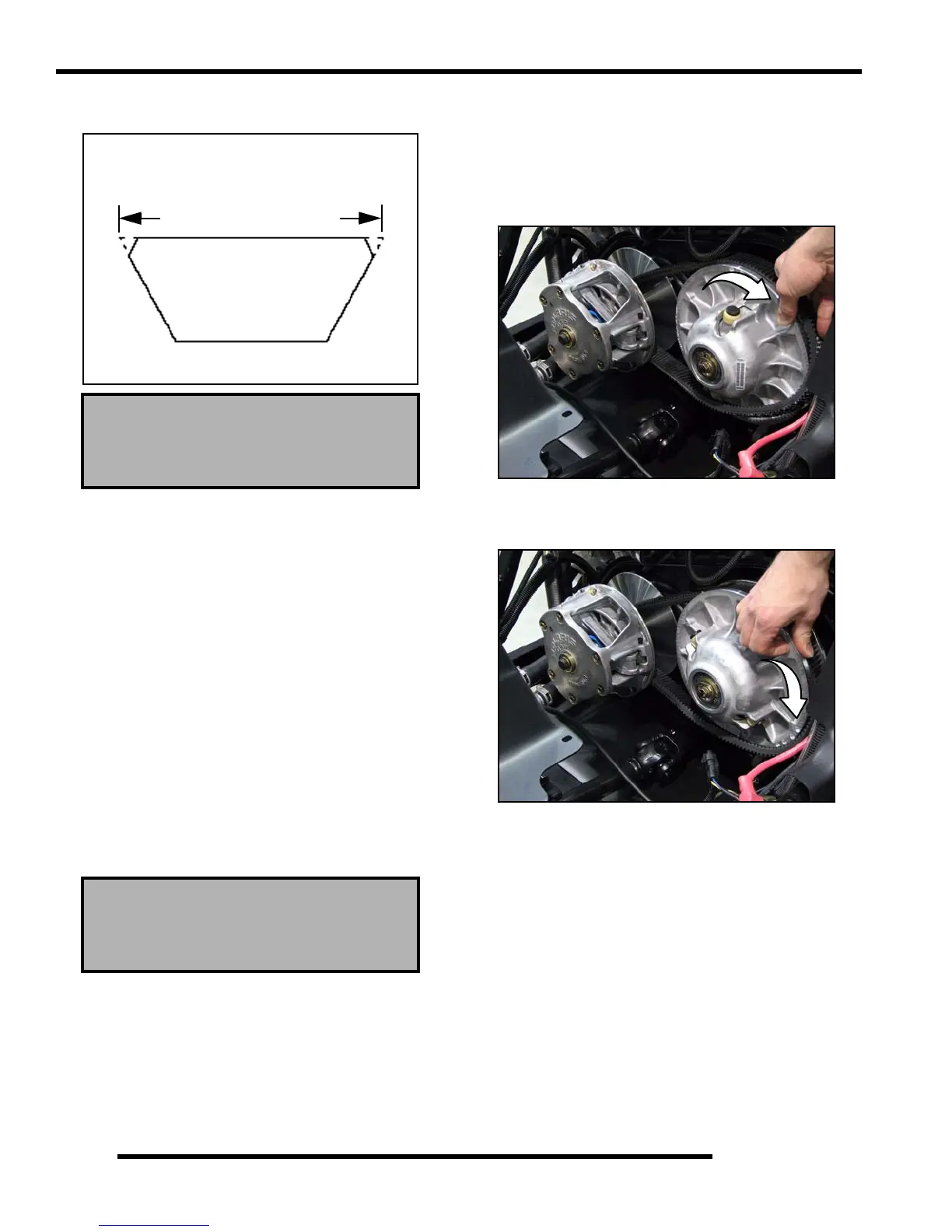

1. Loop belt over the drive clutch and over top of the driven

sheave.

2. While pushing down on top of belt, turn the back, or

moveable driven sheave, clockwise.

3. The belt then should be able to be pushed down into and

between the sheaves.

PVT Break-In (Drive Belt / Clutches)

A proper break-in of the clutches and drive belt will ensure a

longer life and better performance. Break in the clutches and

drive belt by operating at slower speeds during the 10 hour

break-in period as recommended (see Chapter 3 “Engine

Break-In Period” for break-in example). Pull only light loads.

Avoid aggressive acceleration and high speed operation during

the break-in period.

Belt Width

New: 1.188” (3.02 cm)

Wear Limit: 1.157 (2.94 cm)

Belt Outer Circumference

New: 40.89” (103.85 cm)

Wear Limit: 41.08” (104.34 cm)

Projected Belt Width

Loading...

Loading...