Display, Alarm and Error Messages

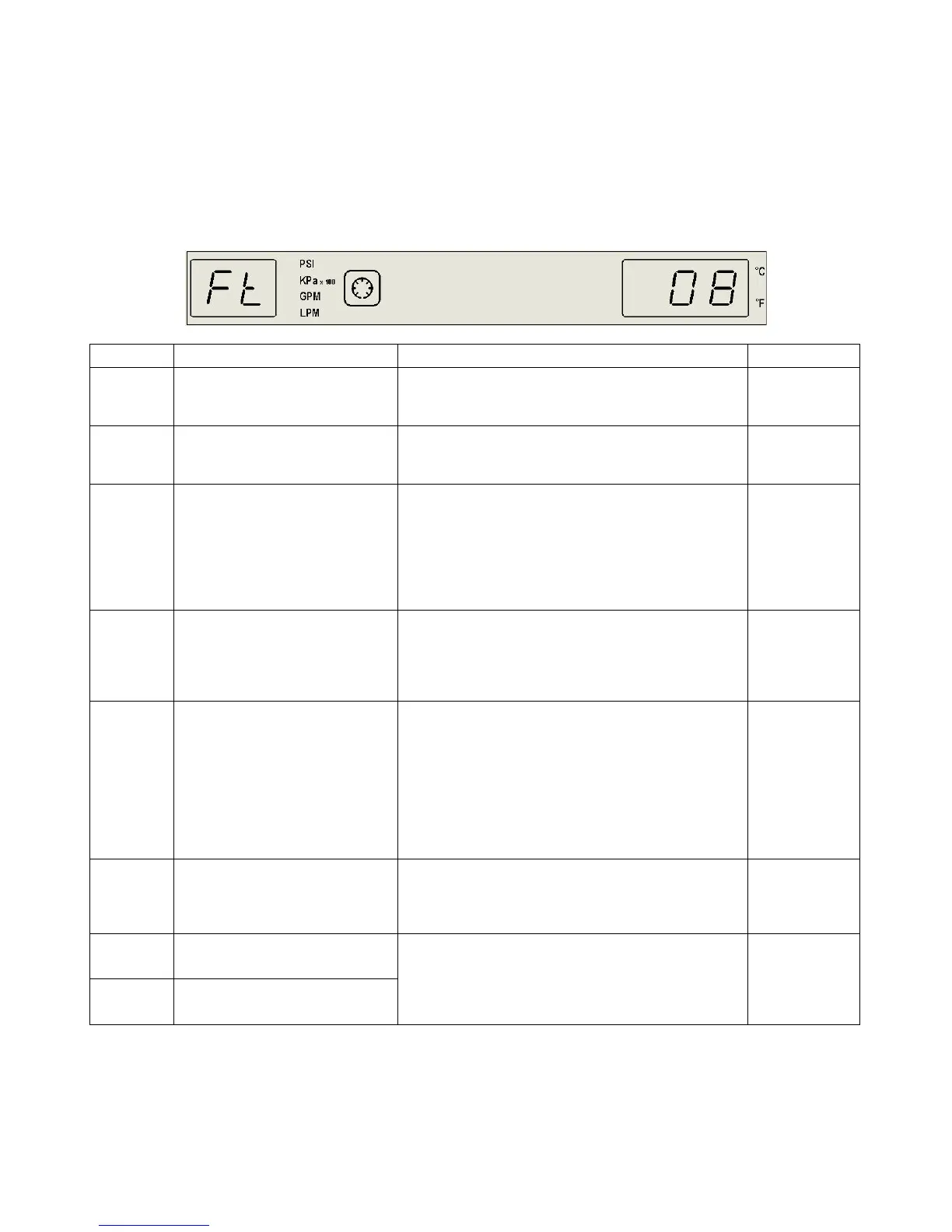

When an alarm or error condition is detected, Ft appears on the Pressure/Flow Rate Display and a

corresponding code flashes on the Temperature Display. Operational limit parameter alarms will shut down the

compressor, fan, pump, and heaters. Alphabetical codes will also appear on the Temperature Display. An audio

alarm will also sound.

After taking corrective action, restart the Chiller to clear the fault or error.

Code Description Action Required Default

02

Low limit temperature alarm

Alarm – Process fluid temperature has dropped

below the low limit temperature setting.

Increase heat load or decrease LL setting.

39°F (4°C)

03

High limit temperature alarm

Alarm – Process fluid temperature has reached the

high limit temperature setting.

Decrease heat load or increase HL setting.

95°F (35°C)

04

Over-temperature alarm

(select models only)

Alarm – Process fluid temperature is above the

factory set high temperature cutout.

Air-cooled units: Cutout will reset automatically after

the temperature of the fluid is lowered.

Water-cooled units: Reset cutout manually by

pressing red button on rear of unit after the

temperature of the fluid is lowered.

Units without

heater option

“OPT”

jumpered on

PCB

05

Low liquid level alarm

(units with Liquid Level Float

Switch option only)

Delayed Alarm – Activated when the liquid level in the

Reservoir falls below an acceptable level for 30

seconds.

Wired in series with mechanical flow switch; see 07

low flow alarm.

See Fuse Bit

settings

07

Low flow alarm

Alarm – Flow rate has dropped below minimum flow

rate setting.

Correct low flow condition or decrease FL setting.

Secondary: Mechanical flow switch closes with flow

(~4 gpm / 15 lpm minimum). If installed in

combination with optional liquid level float switch,

they are wired in series and both must be closed. If

either is open due to low flow or low liquid level, this

alarm or EFL will be activated. See EFL.

~4 gpm

(15 lpm)

minimum

required for

flow switch

08

High pressure alarm

Delayed Alarm – Activated when the fluid outlet

pressure has exceeded the high pressure limit setting

for 30 seconds.

Decrease outlet pressure or increase FP setting.

100 psi

(689 kPa)

09

Internal software fault

10

Triac fault

Fault – Default unit to °C or °F. If fault persists,

replace Control PCB.

Note: Some parameters will reset to default values;

this could activate another fault code. Review and

return all parameters to user settings.

N/A

110-279 31

Loading...

Loading...