Routine Maintenance

Recommended Routine Maintenance Schedule

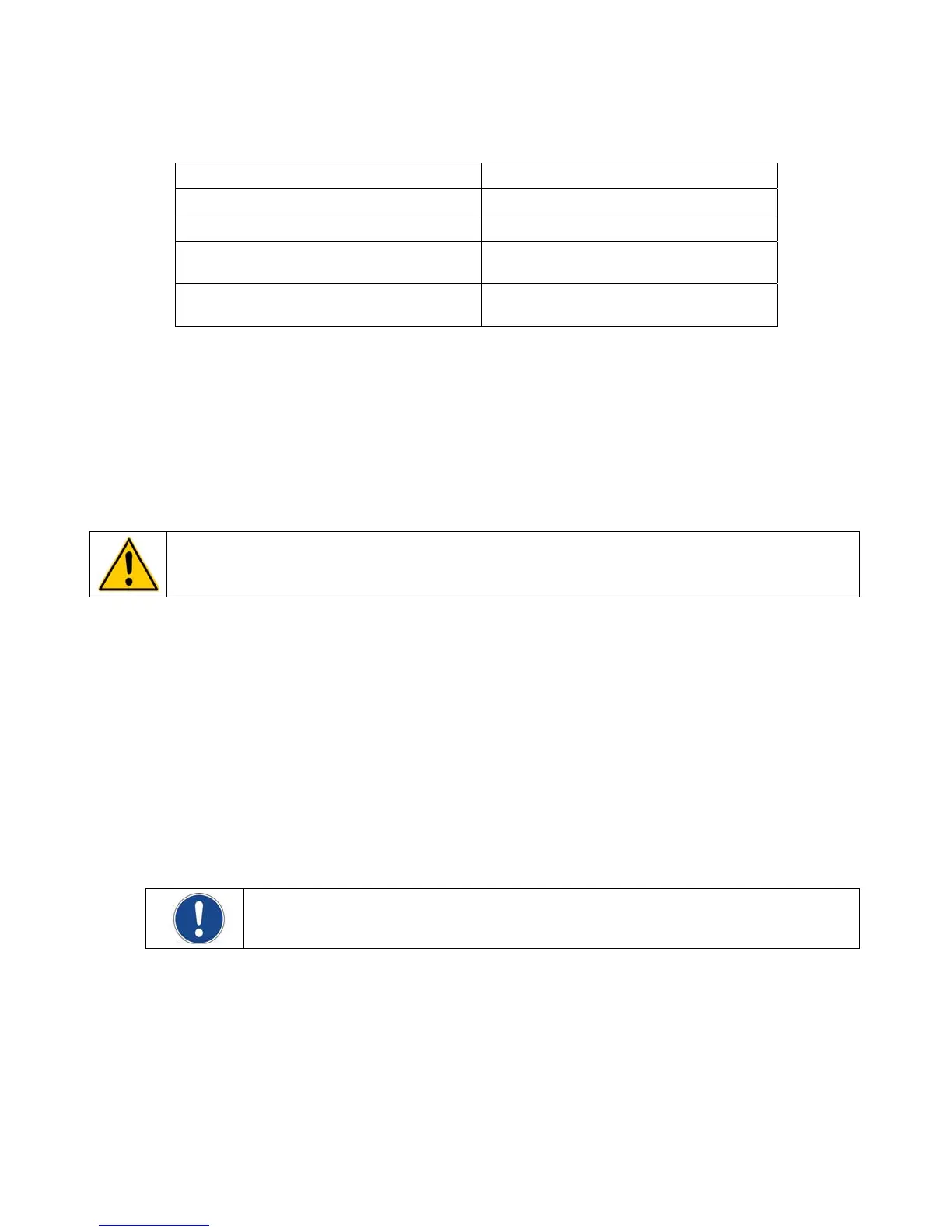

Routine Maintenance Procedure Frequency

1

Check reservoir coolant level Monthly

Check coolant freeze protection Monthly

Inspect and clean inline strainer Weekly for first month of operation;

every 3 months thereafter.

Inspect and clean air filters Weekly for first month of operation;

every 3 months thereafter.

1. Minimum maintenance frequency. Your plant conditions may require more frequent inspection and

cleaning.

Reservoir Coolant Level

The coolant level in the Reservoir should be checked on a monthly basis and replenished as required. A proper

fill level is approximately 2 inches (5.1 cm) below the top of the Reservoir. If fluid replacement is required, slowly

add coolant until the proper fill level is achieved. You may add coolant either directly to the Reservoir or through

the top of the Liquid Level Sight Glass on the rear of the unit.

Coolant Freeze Protection

CAUTION: Coolant freeze protection must be 25°F (14°C) below the lowest possible temperature. The

lowest possible temperature is equal to the process temperature minus the Lower Band (Lb) setting. See

Normal Operation, Setting Operational Parameters / Limits.

If your Chiller is operating below 59°F (15°C), it must be protected with an antifreeze solution. The coolant

should be checked periodically for proper freeze protection.

Inline Strainer

The Chiller’s inline strainer should be inspected and cleaned weekly for the first month of operation. Once you

are certain that all debris that has been generated or dislodged has been removed from the process coolant,

strainer inspection and cleaning should be performed every three months or as required, whichever is more

frequent.

1. Place the Power Switch / Disconnect in the OFF position.

2. Remove the Chiller’s left side rear panel. The inline strainer is located just above the Reservoir at the

inlet to the Chiller.

3. Using an adjustable wrench or the proper size hex head socket, loosen and remove the inline strainer

cap and screen.

NOTE: There will be a small amount of residual coolant within the housing of the inline strainer

which will drain out when the cap is removed.

4. Clean the screen. Either water or high pressure air can be used to remove accumulated debris.

5. Replace screen and drain cap and tighten.

6. Place Power Switch / Disconnect in the ON position.

7. Check for leaks before replacing left rear side panel.

110-279 34

Loading...

Loading...