5.2. Drive mounting

This section provides guidelines to select the best mounting location to ensure the optimum performance,

cautions and warnings that you should follow to avoid injury and/or equipment damage.

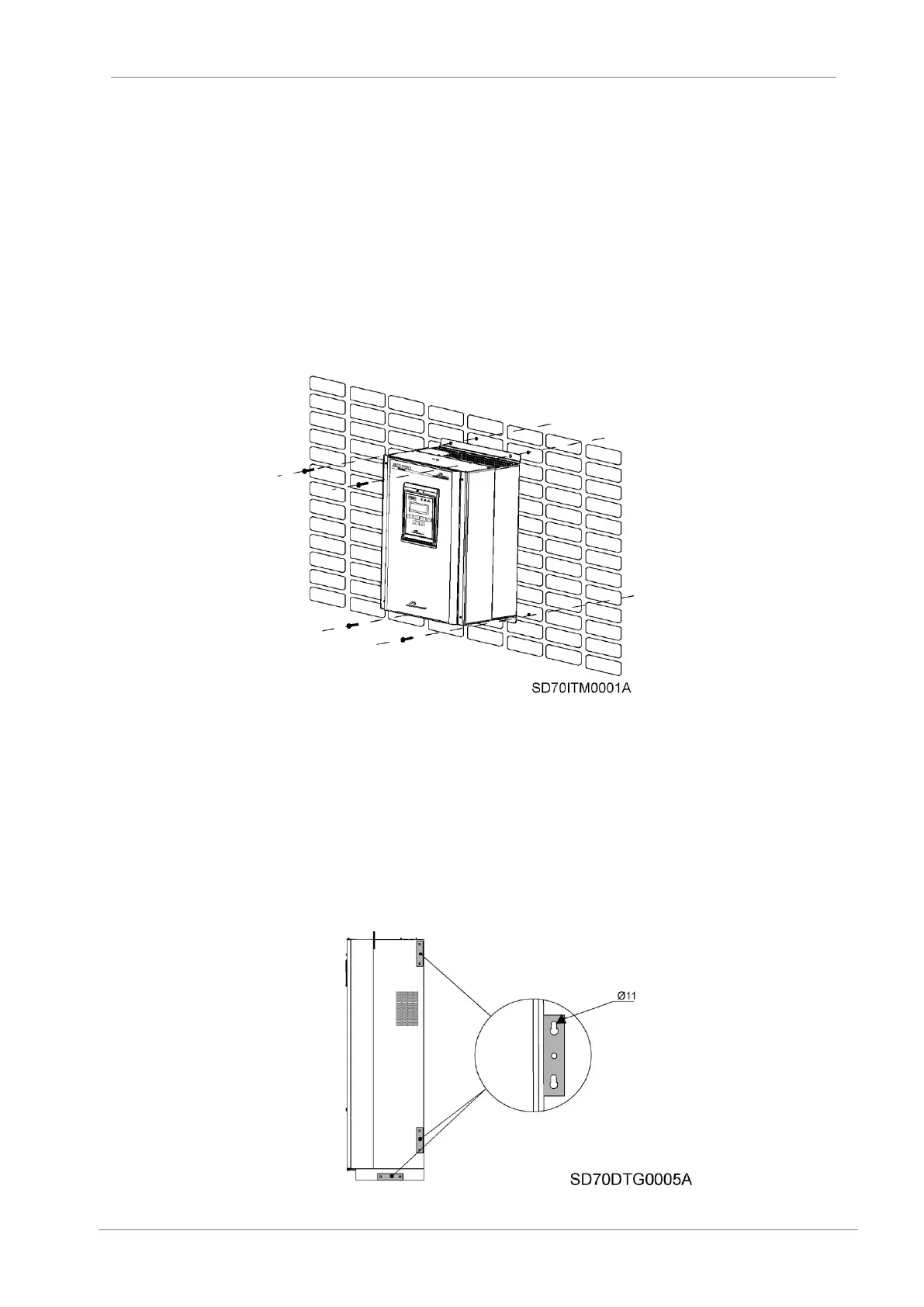

5.2.1. Wall mounting drives

The variable speed drives of the SD700 series from frame 1 to 4 are wall-mounting drives.

Additionally frame 4 has available an optional plinth that converts it into a stand-alone cabinet.

The installation method and mounting location must be suitable for the weight and dimensions of

the drive. Power electronics recommend hanging the SD700 cabinet on a solid wall or structure

through the anchorages placed on the rear part of the drive, which supports the VFD’s weight and

the possible forces generated by the wiring.

Figure 5.1 SD700 wall mounted

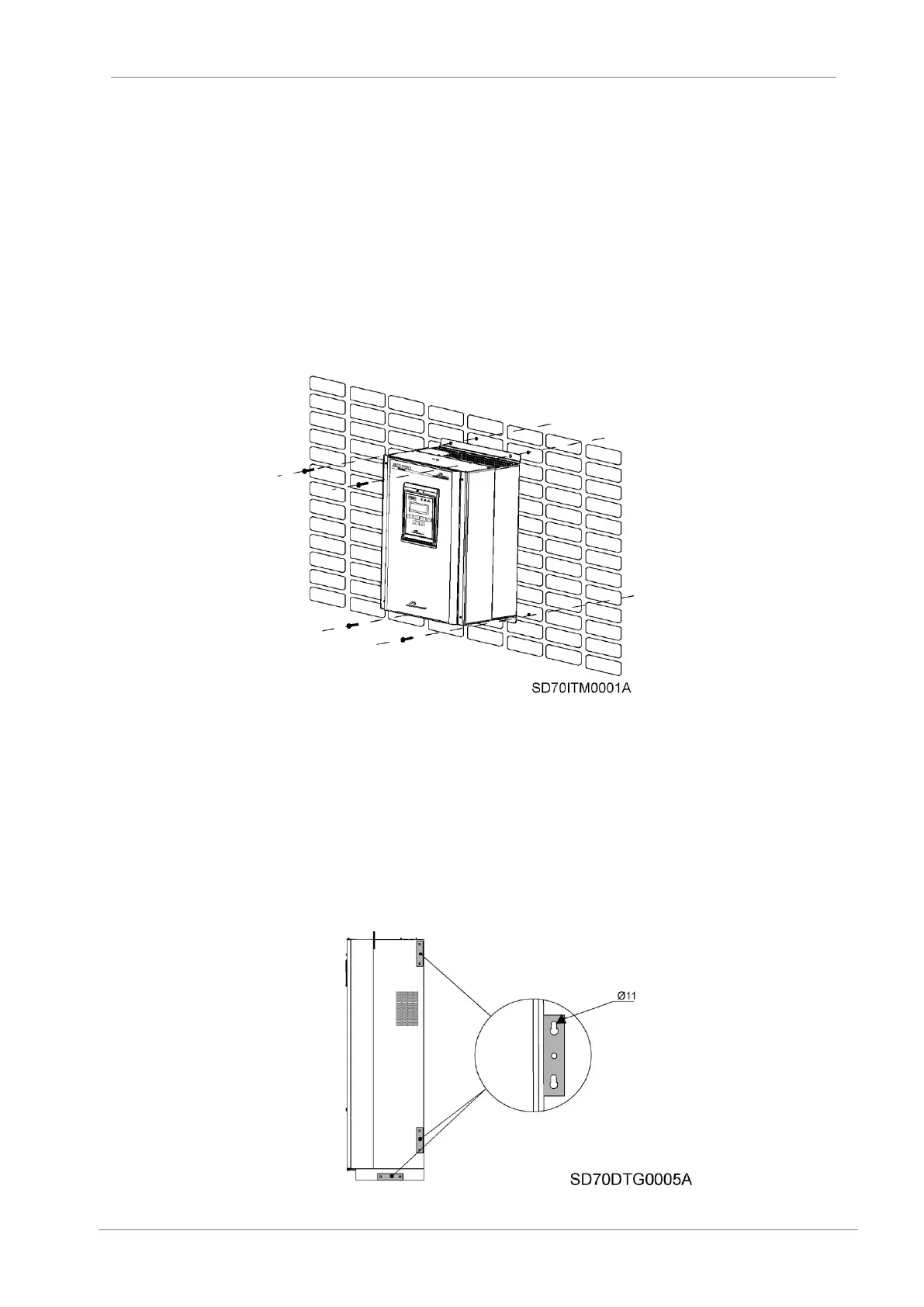

5.2.2. Stand alone drives

Frames 5 to 11 are designed to be placed over a technical floor, if needed there are available

optional plinths that increase the height of the drive from 1710mm to 2000mm or 2200mm. The

floor must guarantee a non-flammable, solid, plain and levelled surface to the drive, a minimum

clearance around it and a smoothly cable access. The maximum allowed slope is 1cm in every 6

meters. The installation site should be levelled, if necessary, as the cabinet is not equipped with

adjustable feet. The walls adjoining the drive must be made of a non-flammable material. Fix the

SD700 cabinets to the wall or floor by using the L brackets placed in both sides of the drive. They

have an Ø11 hole and can be use either in the legs or in the rear part of the drive.

Figure 5.2 Wall or floor fixation

Loading...

Loading...