11. MAINTENANCE

SD700 drives consist of advanced semiconductor devices. Temperature, humidity, vibration and

deteriorated components can reduce their efficiency. To avoid any possible irregularity we recommend

making periodic inspections.

11.1. Warnings

Be sure to remove the input power while performing maintenance.

Be sure to perform maintenance after checking the DC Link capacitor has discharged. Check that the

voltage between terminals +HVDC and -HVDC is below DC 30V. The bus capacitors in the drive main

circuit can still be charged even after the power is turned off.

The correct output voltage of the drive can only be measured by using an RMS voltage meter. Others

voltage meters, including digital voltage meters, are likely to display incorrect values caused by the

high frequency PWM output voltage of the drive.

11.2. Routine Inspection

Be sure to check the following points before handling the drive:

Installation site conditions.

Drive cooling system conditions.

Excessive vibrations or noise in the motor.

Excessive overheating.

Normal output current value on the monitor.

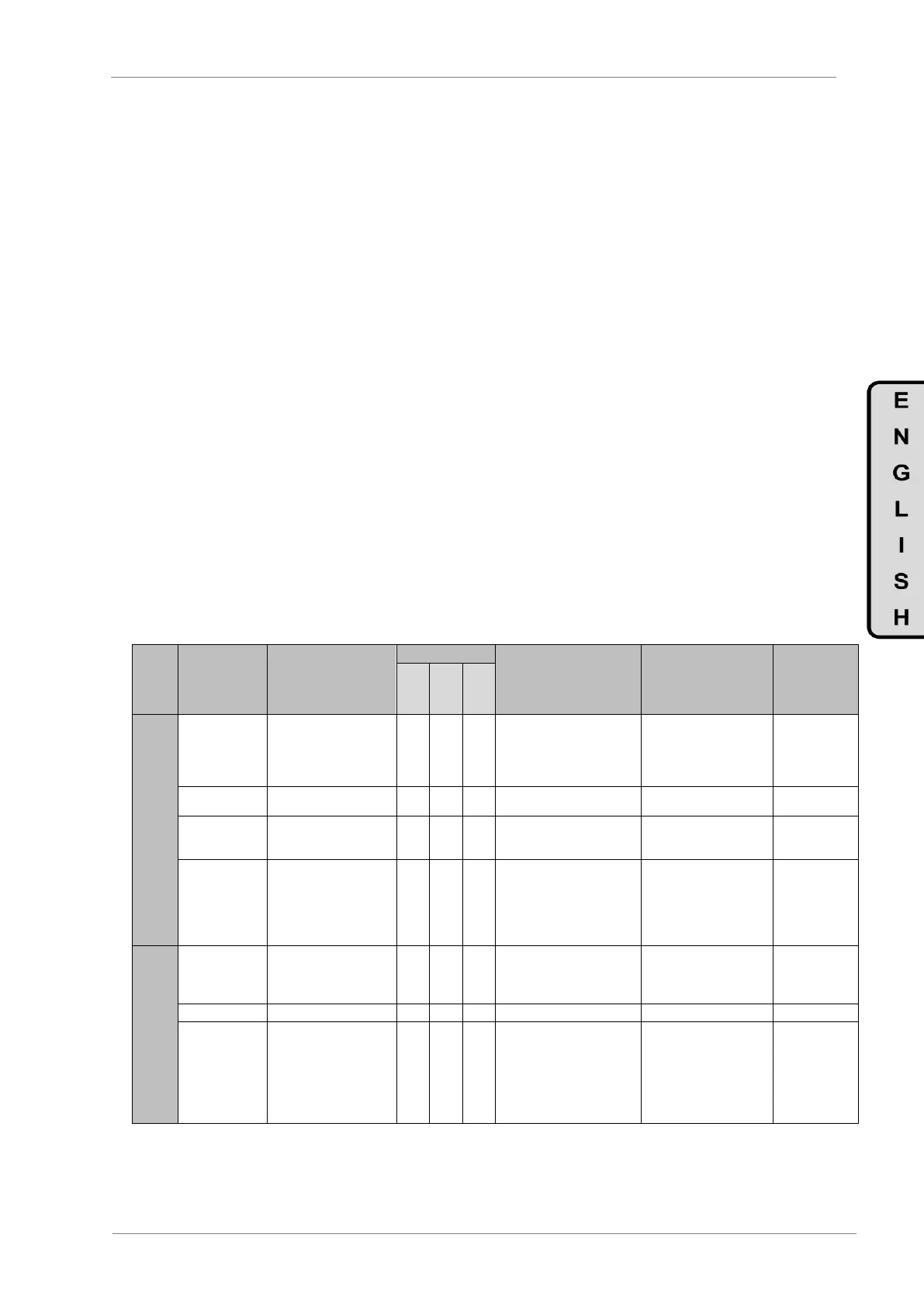

Instrument of

Measurement

Are there dust particles?

Are the ambient

temperature and the

humidity within

specification?

Temperature:

-30 to +50 ( or 40ºC)

Humidity: below 95% non-

condensing.

Thermometer,

Hygrometer,

Recorder.

Are there any abnormal

noises or oscillations?

Is the input power to the

main circuit correct?

Measure the voltage between

terminals L1, L2, L3 and PE.

Digital

multimeter.

Tester.

Are the Power terminals

correctly fastened?

Measure the temperature and

torque of the power

connections

Fasten the bolts again one

week after its start-up.

Check that the

temperature is

homogeneous and below

70ºC

Infrared

thermometer ,

Torque key

Is the conductor

corroded?

Is the sheathing of the

cable damaged?

IGBT's module

Diodes module

and Rectifier

Check the resistance

value between each one

of the terminals

Disconnect the cables of the

inverter and measure the

resistance value between:

L1, L2, L3, VDC+, VDC-

and

U, V, W VDC+, VDC-

with a tester > 10k

Digital

multimeter.

Analogue tester.

Loading...

Loading...