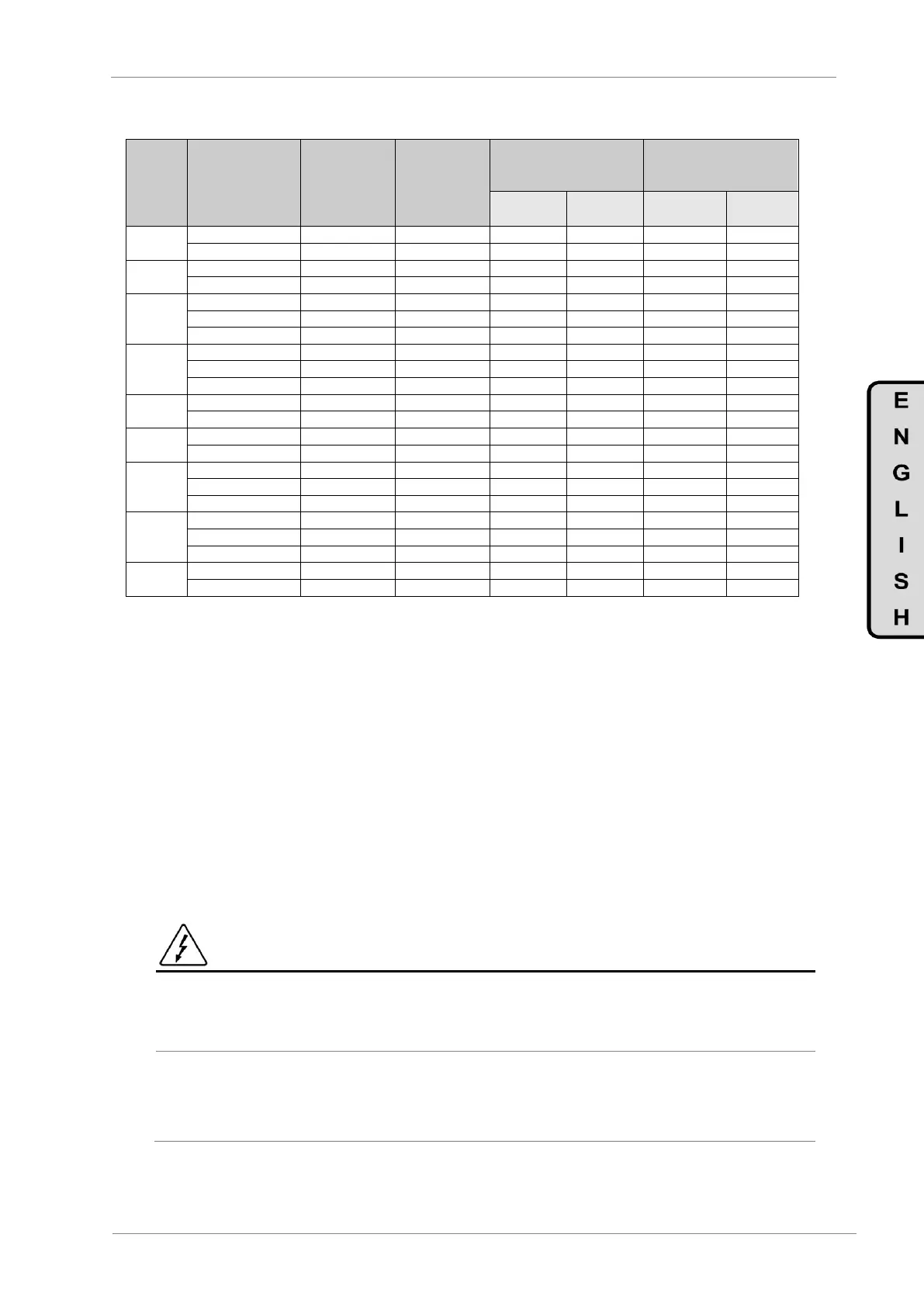

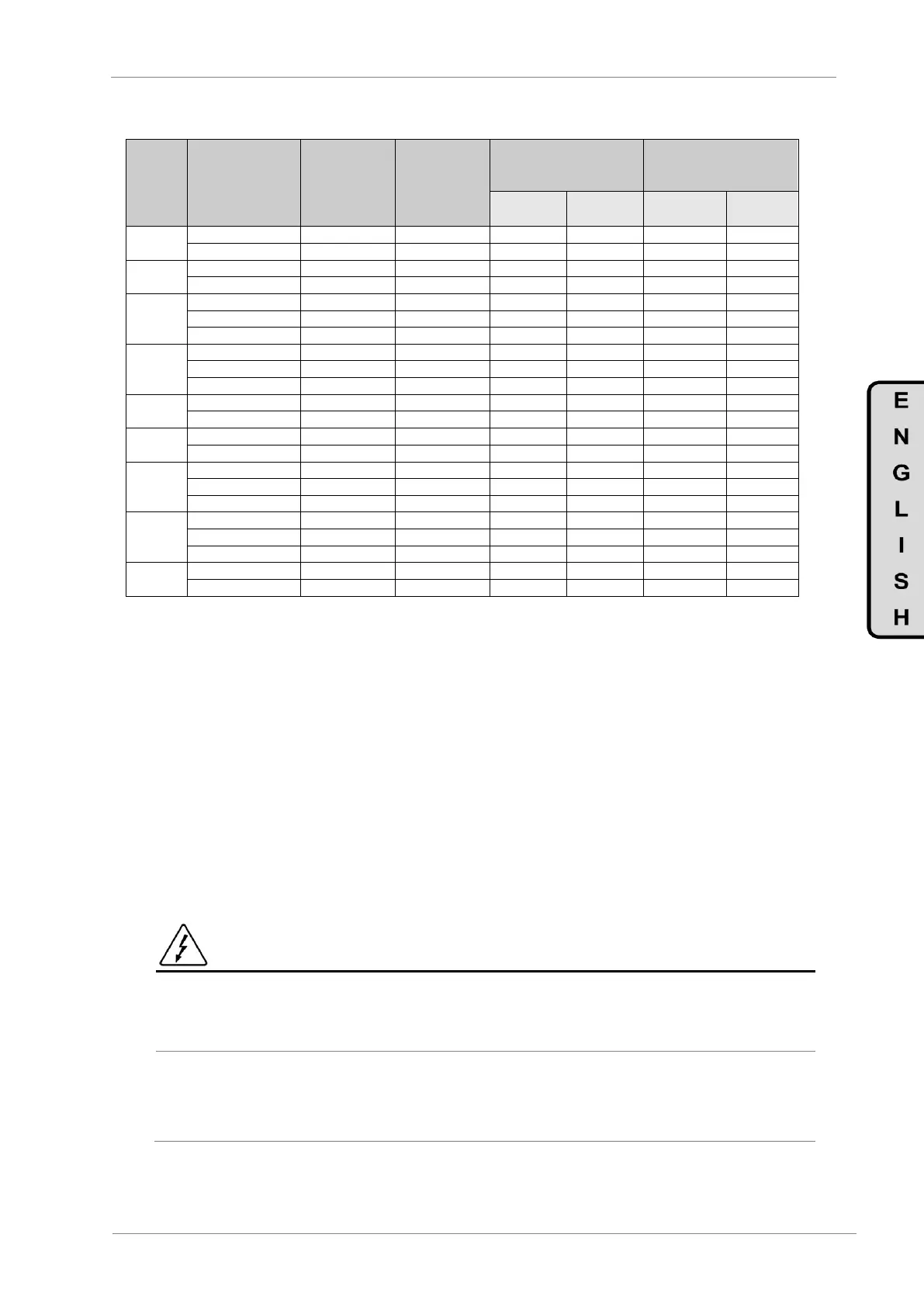

6.3.2. Recommended Cable Section for 690VAC

Recommended

Cable Section

per Phase

Recommended

Cable Section

for Earth Wire

Note: Cable must be suitable for a permanent Tª >75ºC. Use 600V cables for up to 500Vac rated voltage.

For 525Vac and 690Vac phase to phase rated equipment use 1kV cables. However this is only a

recommendation. You must follow the local regulation.

6.4. Ground connection

Before connecting the power conductors, be sure that the chassis of the drive and the adjoining cabinets

are connected to ground through the dedicated (PE) terminals. They are situated at both sides of the bottom

metallic walls of the drive and they are labelled with the appropriate ground connection. Check section

“6.10 Power Terminals”.

Motor’s chassis grounding must be connected to the drive. In other words, connect the motor’s ground

conductor to the PE output terminal of the drive and not to the installation’s ground. We recommend that

the cross section of the motor’s ground conductor (PE) should have at least the cross section of the active

conductor (U, V, W). Additionally, it should be installed following the recommendations indicated in section

“6.3 Power Connection and wiring”.

When connecting the earth, ensure that all connected terminal lugs are securely tight and protected from

mechanical forces. The tightening torque in case of M10 PE terminals is 40Nm.

CAUTION

For safety reasons it is determinant to measure the grounding resistance of the plant itself. This

must be established before the first start up of the plant and with the drive disconnected.

It is responsibility of the installer to provide the adequate number, type and cross section

grounding conductor alongside with the characteristics of the drive used and of the Plant in order to

minimize the grounding resistance, that comply with the local and national regulation.

Loading...

Loading...