7.4. Connection with ATEX motors

ATEX regulations and guidelines are related to the regulations governing the use of machinery, installations

or equipment within potentially explosive atmospheres. In the European Union, the use of equipment within

these areas becomes a legal requirement described in two complementary directives: Directive

1999/92/EC for the installation environment and workers protection, and Directive 94/9/EC for the ATEX

equipment. These guidelines and directives are based on two basic concepts: the classification of

potentially explosive areas or zones, and the branding of products that are able to be installed within a

zone.

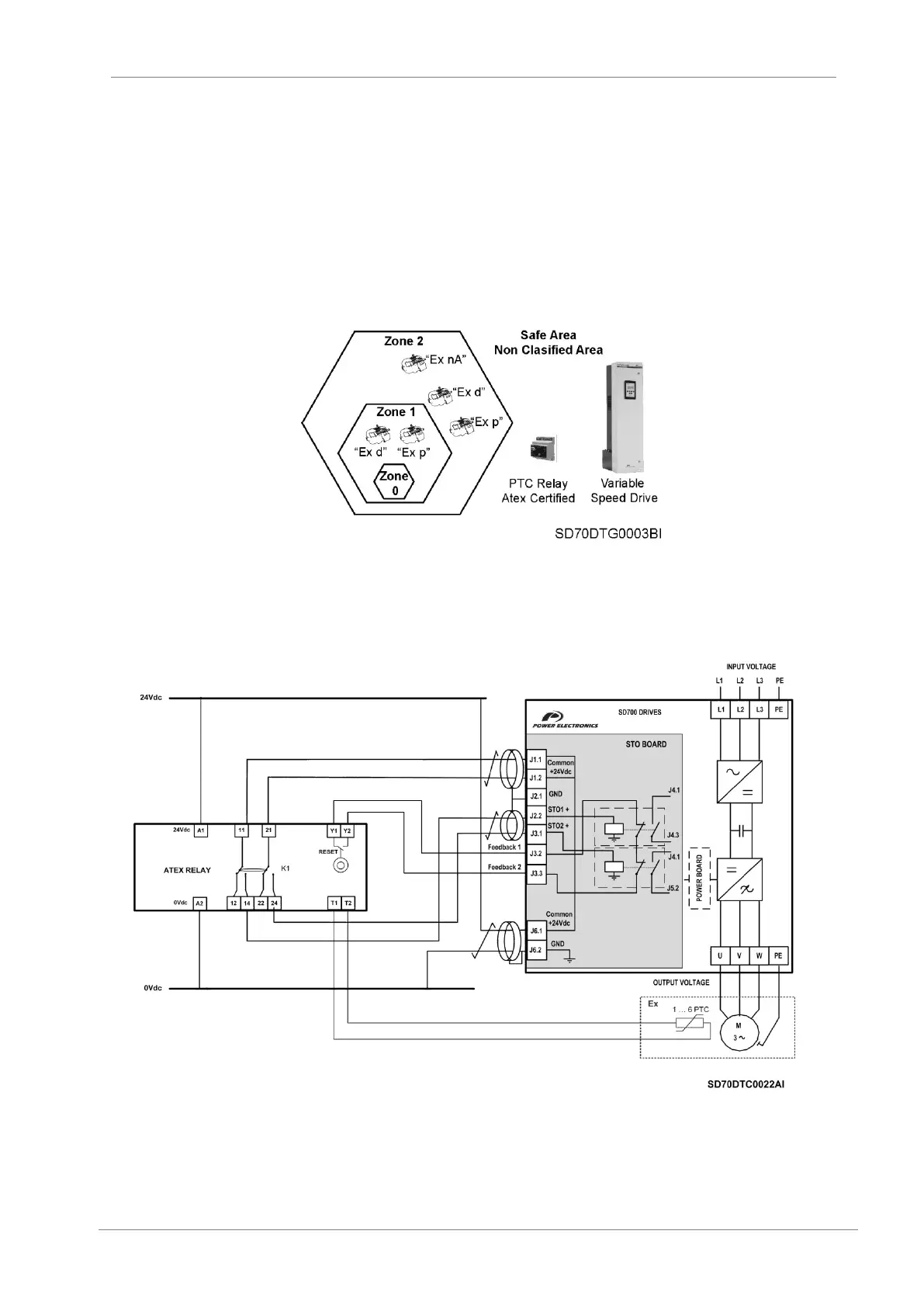

Power Electronics provides a solution for driving ATEX motors such as “Ex nA”, “Ex d” and “Ex p”, under

the ATEX zone areas illustrated below. For different ATEX motor and zone combination, consult Power

Electronics.

Figure 7.10: Atex motors and Zones combination

The solution is valid for motors with type of protection "Ex d" or “Ex p” installed in ATEX zone 1 and 2, or

motors with type of protection "EX nA" located in zone 2. The external PTC relay must be ATEX certified,

and compatible with the following features: 24Vdc power supply, 2 safety input terminals, at least 2 NO

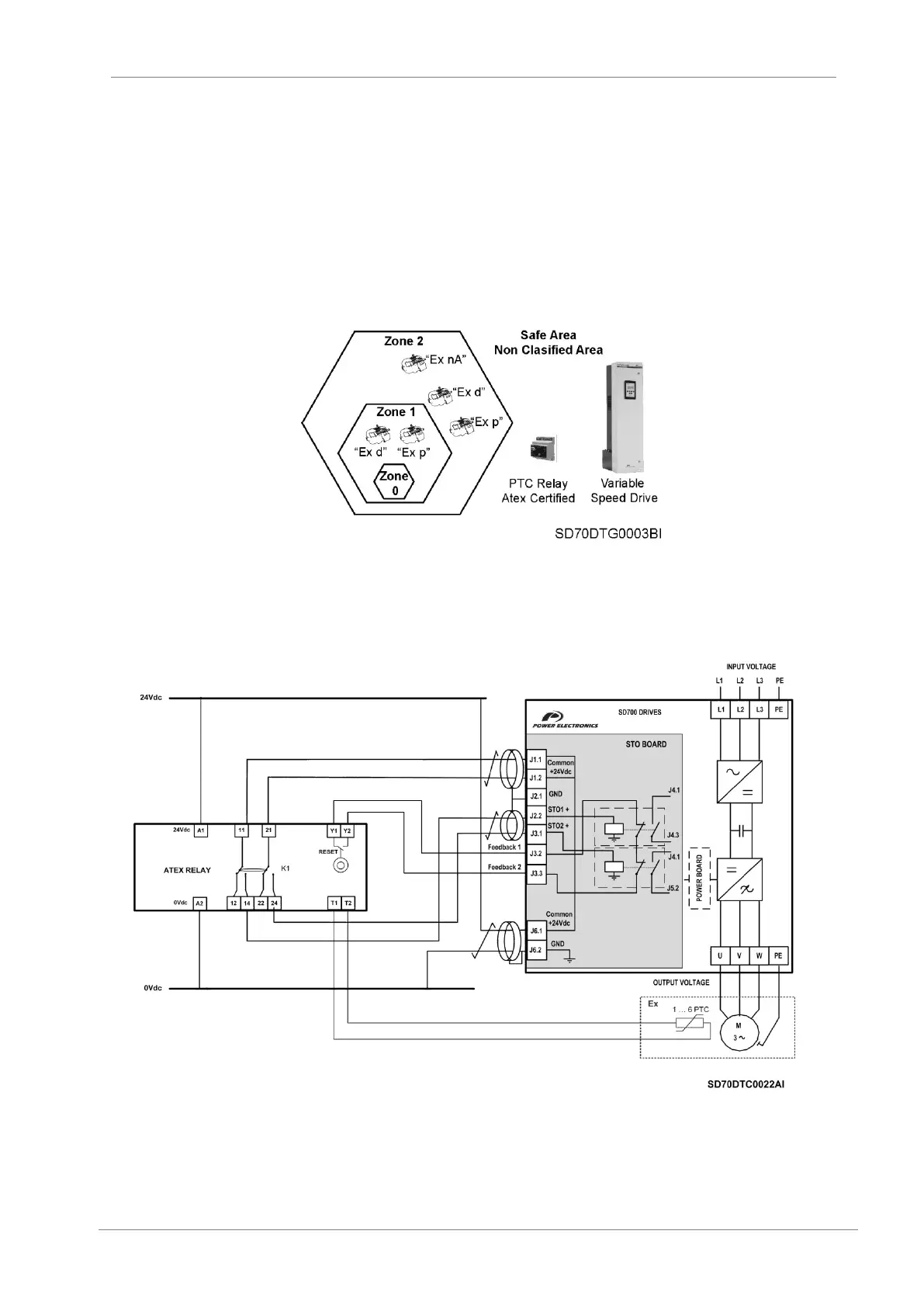

and a reset function. As illustrated below, the SD700 drive and ATEX relay must be place in a safe area,

outside the ATEX zone. (Example: ZIEHL -PTC MSR 220 Vi)

Figure 7.11: Connection scheme (Example with ZIEHL -PTC Thermistor Relay Type MSR 220 Vi)

SD700 series are built-in as standard with dV/dt filter and a unique CLAMP system that reduce the dV/dt

and voltage peaks at the motor windings. Therefore, it reduces the risk of winding sparks, motor

overheating and bearing currents.

Additionally, the motor thermal mode protection could be adjusted to increase the protection against motor

overheating. In case of self-ventilated motors, it could be required to apply a derating to the drive according

to the motor manufacturer derating curves.

Loading...

Loading...