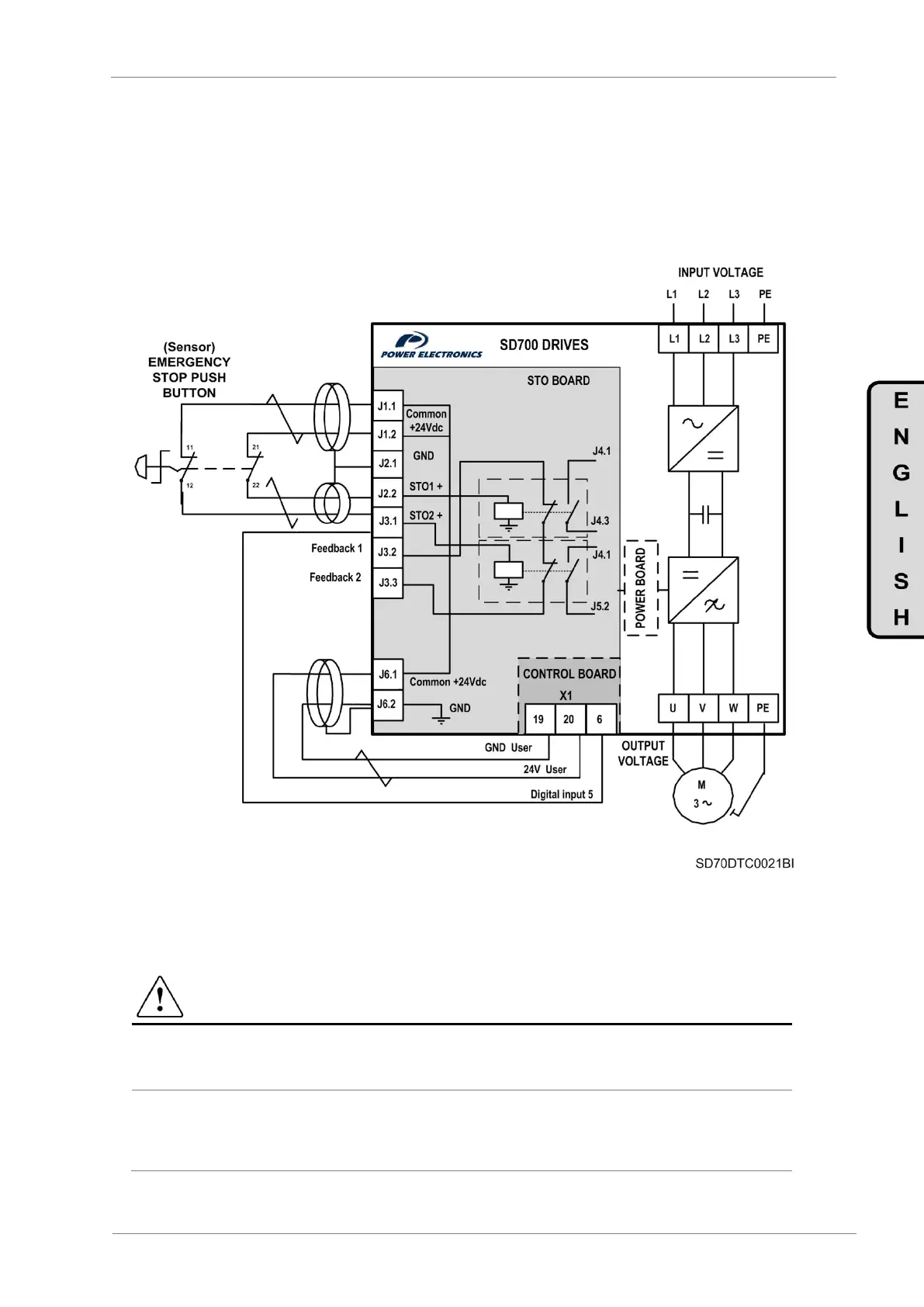

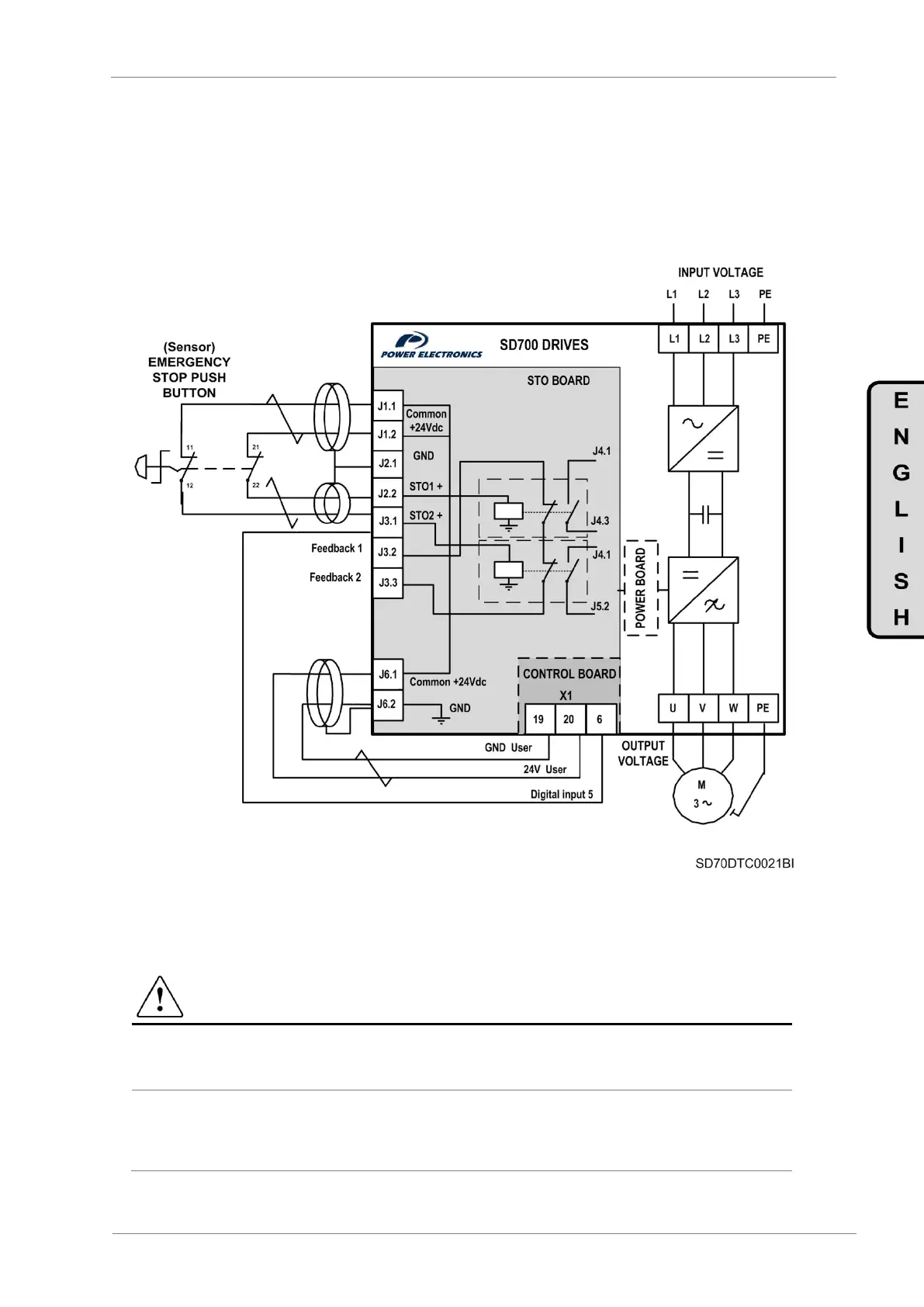

7.3.2. Safety Integrity Level SIL1- PLc

This connection scheme provides an easy and cost effective solution for installations that not

require the highest safety level requirements. In this case, the two NC contacts from the external

push button are directly connected to the optional STO board. As the previous solutions, the

operator pressing sensor will deactivates the IGBT switching of the inverter bridge through two

independent channels, disconnecting the motor power supply and avoiding any possible

unexpected restart. The monitoring terminals will not be connected. To ensure a correct drive

response when a fault occurs, J3.1 terminal must be connected to the digital input 5 of the SD700,

previously set as external fault (G4.1.9 option 24 EXTERN EMERGE).

Figure 7.9 Emergency Stop Push button connection scheme – SIL 1 -PLe

X1.19 and X1.20 terminals can be used for other purpose depending on the inverter applications

(frequency reference performed by an external potentiometer, analogue feedback etc…). In order

to avoid the multiple cable connection in a single terminal (X1.19, X1.20), it is recommended to add

additional external terminals to distribute the power supply.

CAUTION

According to EN 60204-1 automatic restart is not allowed after an emergency stop. For this reason

the machine control must prevent an automatic start after emergency stop.

To ensure a correct drive response when a fault occurs, J3.1 terminal must be connected to the

digital input 5 of the SD700 drive, previously set as external fault (G4.1.9 option 24 EXTERN

EMERGE).

Loading...

Loading...