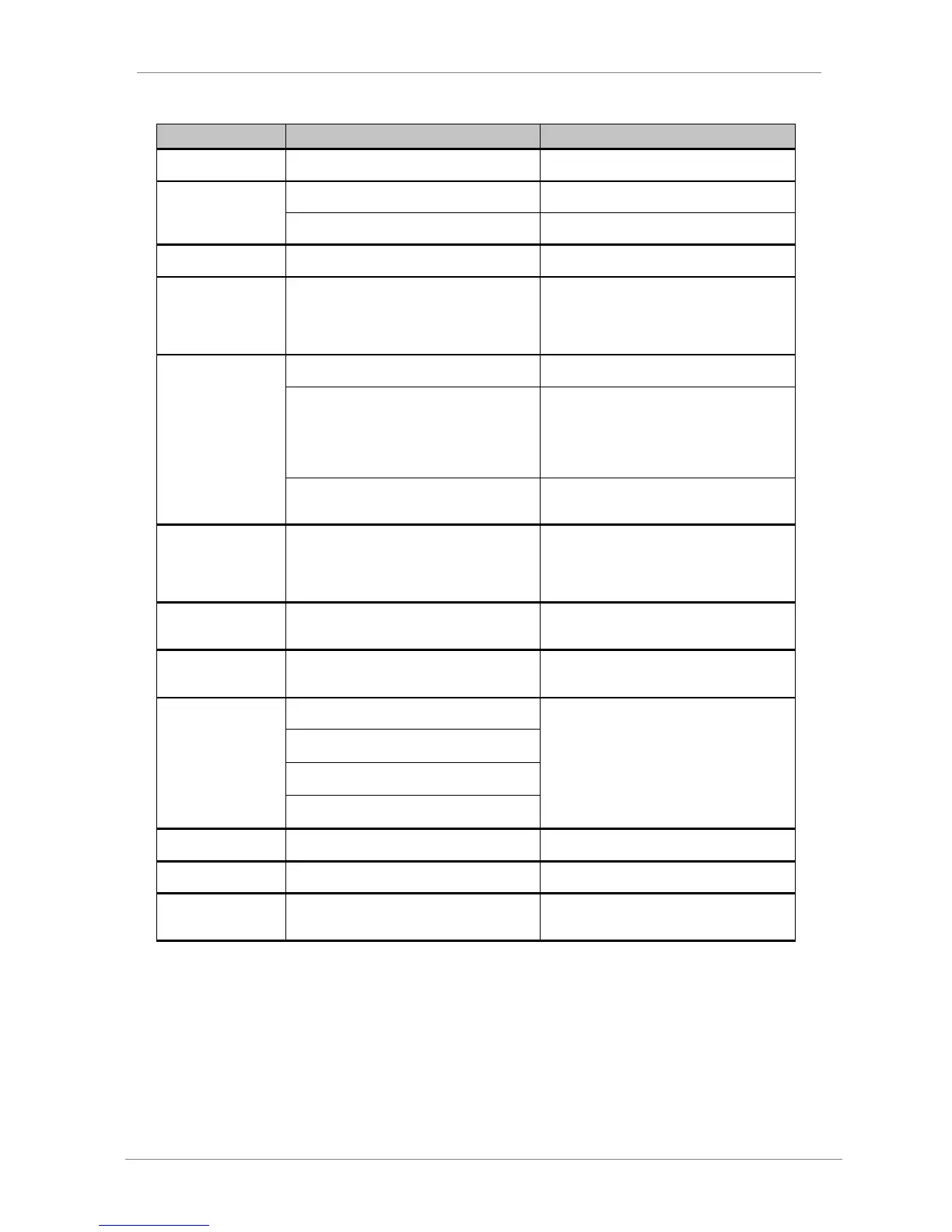

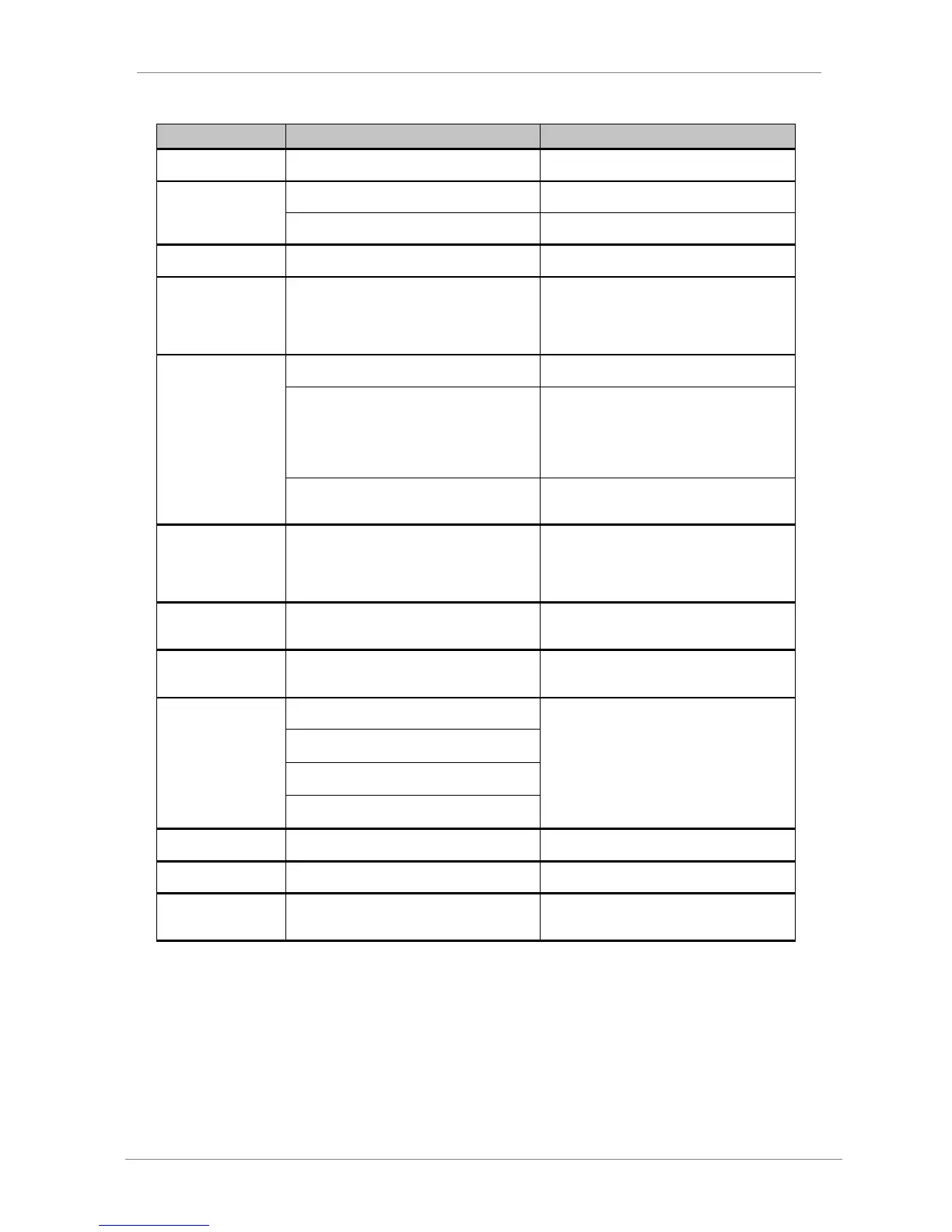

FAULT MESSAGES. DESCRIPTIONS AND ACTIONS

Reset the equipment and if the fault persists

request technical assistance.

Speed reference is higher or equal than the

speed limit.

Check the reference source and the motor load.

Motor speed is out of control or motor is

accelerating because of the load.

Reset the equipment and if the fault persists

request technical assistance.

Temperature limits for SD700FR rectifier have

been exceeded.

Verify that the ambient conditions are proper for

the equipment.

Be sure that there is nothing obstructing the

cooling fans (dust, papers, dirt, etc) and that

these rotate correctly.

Fans of the equipment are operating wrong.

Verify that fans are not obstructed.

Check that fans are not dirty and rotate correctly.

Power supply of the fans has been overheated.

Wait for the temperature of the power supply

decreases down to a value in normal conditions

and restart it. You can disconnect the equipment,

connect it again, and restart the power supply

again. If the fault persists request technical

assistance of Power Electronics.

Drive power supplies are faulty and the rectifier

bridge has reached 90ºC.

Check the correct status of the power supplies. If

the fault persist request technical assistance of

Power Electronics.

The limit of internal temperature of the electronics

chamber has been exceeded.

Verify that the ambient conditions are proper for

the equipment.

Be sure that there is nothing obstructing the

cooling fans (dust, papers, dirt in general) and

that these rotate correctly.

A fault in the microcontroller has occurred.

Disconnect and re-connect the input power of the

drive. If the fault persists request technical

assistance of Power Electronics.

An external trip has been produced by closing a

contact on the digital input configured in this

option.

Verify the wiring of digital input.

Check the installation.

High current used by the motor due to heavy

load.

Check the motor load.

Check if the motor cooling is appropriate.

Check the setting of the parameters related to

pump overload in group G11.

The load exceeds the capacity of the motor

cooling under normal operating conditions.

Incorrect setting of the parameters related to

pump overload.

Phase loss of the motor or a fault in motor

windings.

The communication between Profibus Master and

Slave is cut off.

Revise the Profibus wiring and the configuration

in the Master (PLC).

The active connection with the Ethernet/IP Client

has been lost.

Check the Ethernet/IP connection of the client

(PLC, PC).

The start command has been given while the

drive is powered through the External 24V Power

Supply.

Restore 3-Phase power supply to the drive before

giving the start command.

Loading...

Loading...