Premier Tech 30 / 64 Solido SMART

DOKK5110E 15.04.2020

6.6 Desludging

• Make sure of desludging (on demand) if SSV90

norm

-level (referred to HRmax) is

reaching 700 ml/l (measure with dilution 1+3 and multiply result by 4).

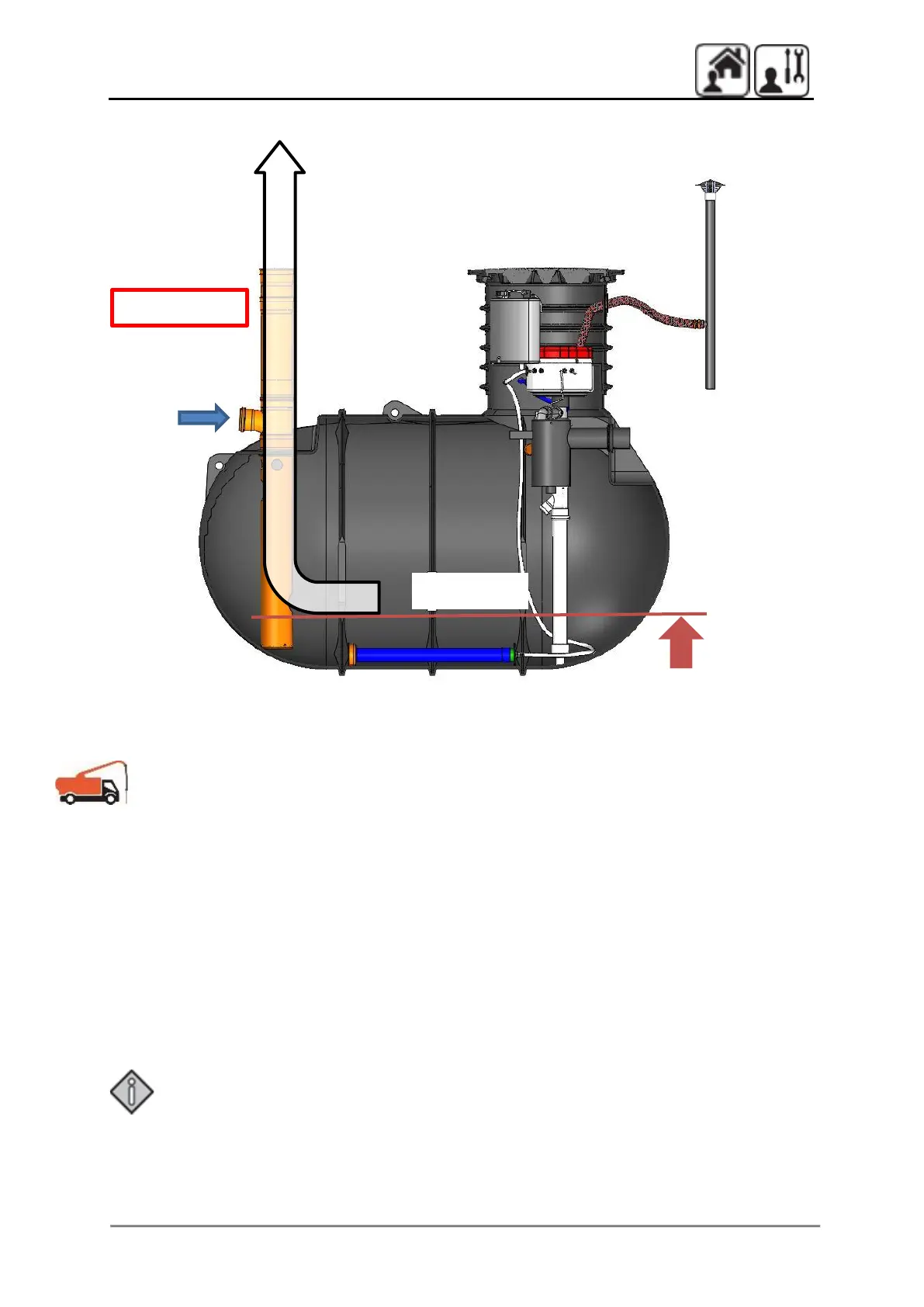

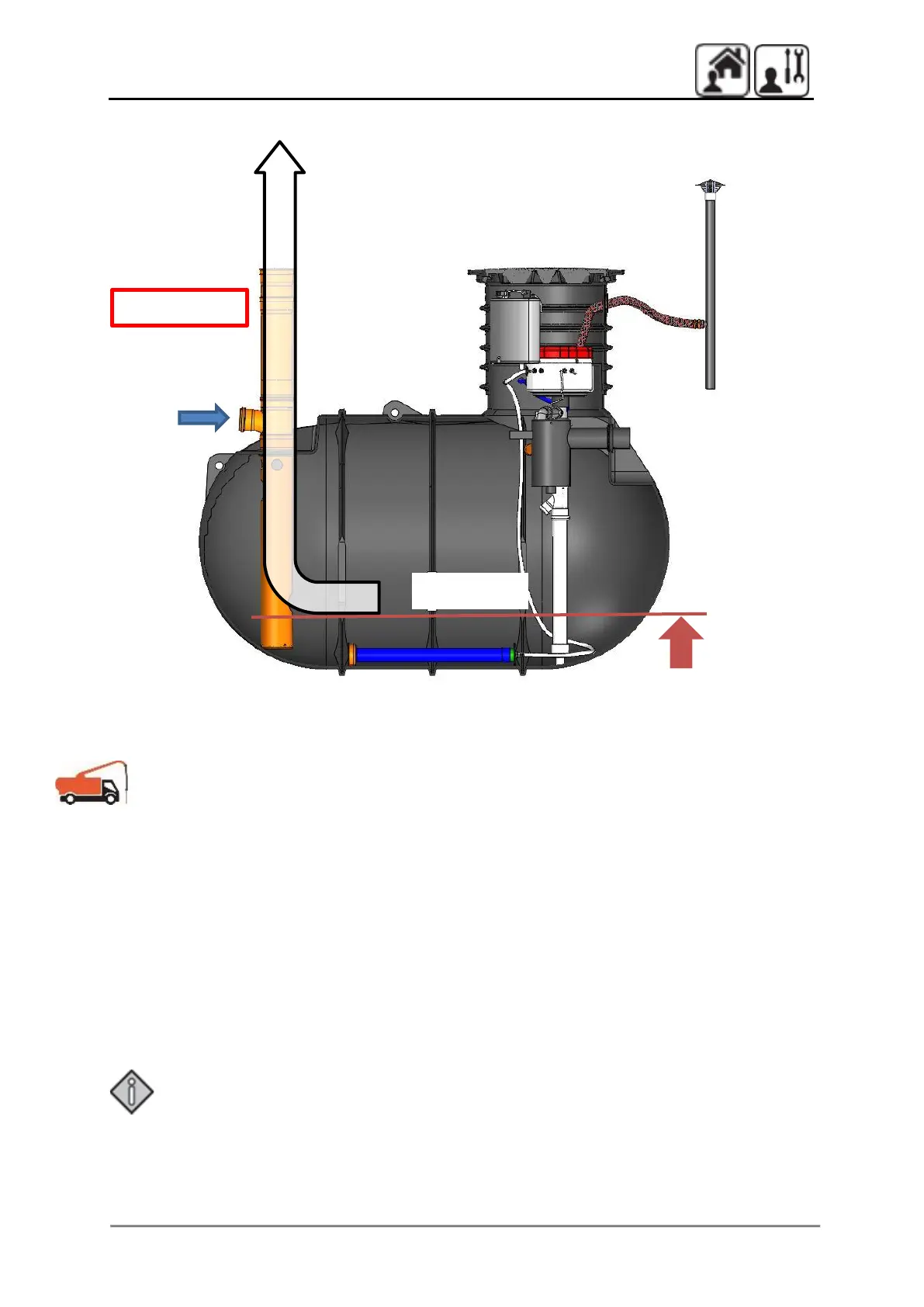

• For desludging make sure to use integrated desluding/inspection pipe (d=160mm)

indicated by this pictogramm only, in order to enable proper desludging and to

prevent damage to components.

• Avoid desludging during sedimentation phase (around 12 to 2pm).

Recommended: between 2 and 3 pm, low water level after clearwater discharge.

• There is no need to open the lid of the system or take out the capsule for desludging.

• The design of the pipe will make sure that at least 10% of the volume will stay inside

the tank. This is mandatory to keep up the performance of the plant right after

desludging.

• It is recommended to fill up tank with water after desludging (around 1/3 of max. level)

• Make sure to document desludging in operations logbook

With SMART+P EM2 (two chamber tank M2) the desludging is done in the same way.

There is an opening in the baffle at a specific height, in order to desludge the first

chamber almost completely and leaving a water level of about 25cm in the second

chamber. Considering the whole volume there will remain enough sludge to continue

the biological process.

Loading...

Loading...