ProMinent

®

Page 37

Technical Data

14.2 Dosing reproducibility

Standard Liquid ends

Dosing precision -5 to +10% at max. stroke length and max. operating pressure for all materials.

Reproducibility ±2 % at constant conditions and minimum 30 % stroke length.

Self-degassing liquid ends

Since self-degassing liquid ends are filled with air bubbles when in contact with gaseous

chemicals and when in operation, no dosing reproducibility values can be given.

The recommended minimum stroke length with self-degassing liquid ends is 50 %.

14.3 Viscosity

The liquid ends are designed for liquids up to a maximum viscosity of

• 200 mPas for standard liquid ends

• 500 mPas for valves with springs

• 50 mPas for self-degassing liquid ends

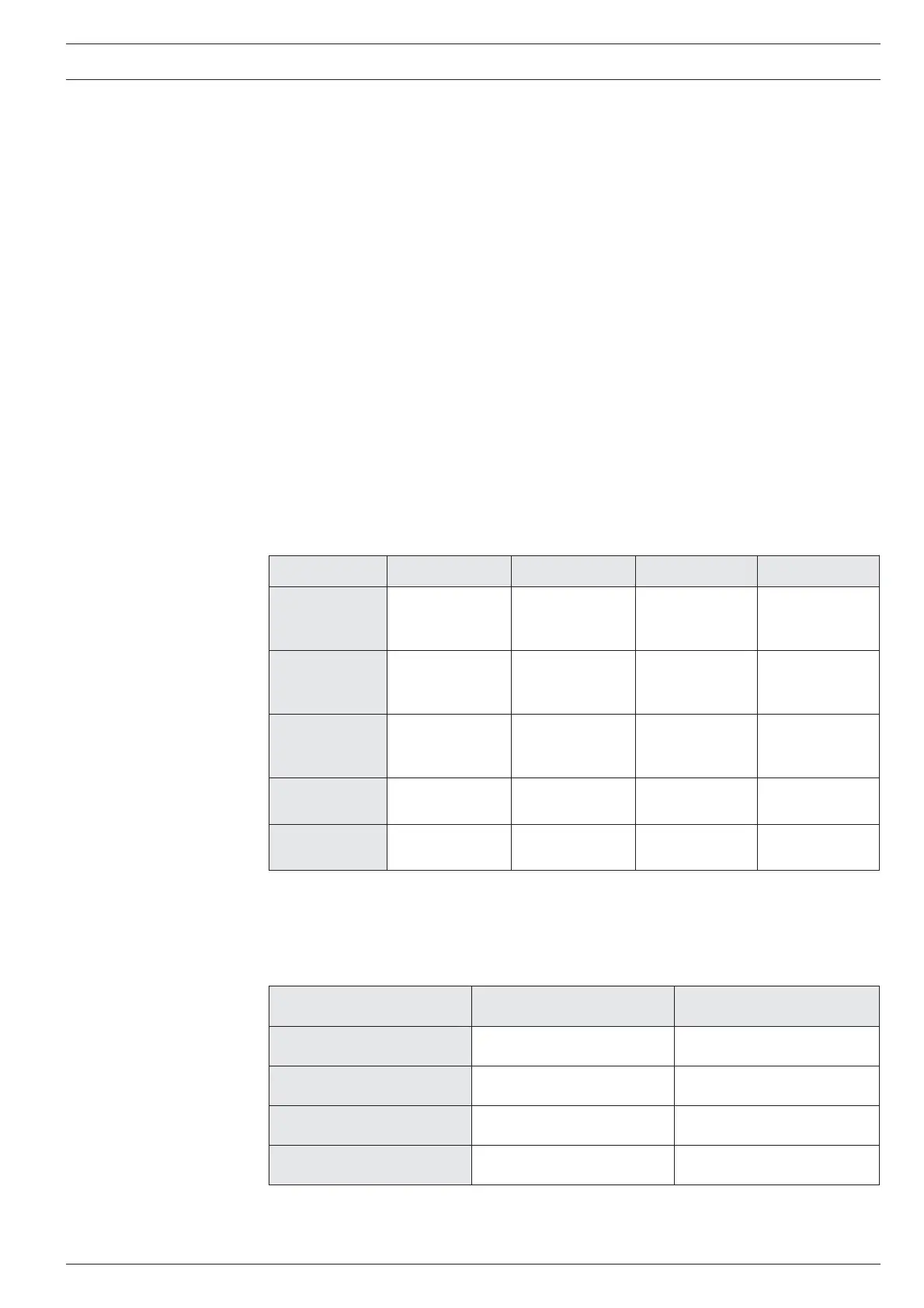

14.4 Materials Data for Liquid ends

noisreV dnediuqiL sevlaV slaeS sllaB

EPP

BPP

PP

PP

PP

PP

MDPE

notiV(MPF

®

)

cimareC

cimareC

ECP

BCP

CVP

CVP

CVP

CVP

MDPE

notiV(MPF

®

)

cimareC

cimareC

EPN

BPN

ssalgcilyrcA

ssalgcilyrcA

CVP

CVP

MDPE

notiV(MPF

®

)

cimareC

cimareC

TTT

htiwEFTP

nobrac

htiwEFTP

nobrac

EFTPcimareC

TSS

leetssselniatS

1754.1

leetssselniatS

1754.1

EFTPcimareC

Viton

®

(FPM) is a registered trade mark of DuPont Dow Elastomers.

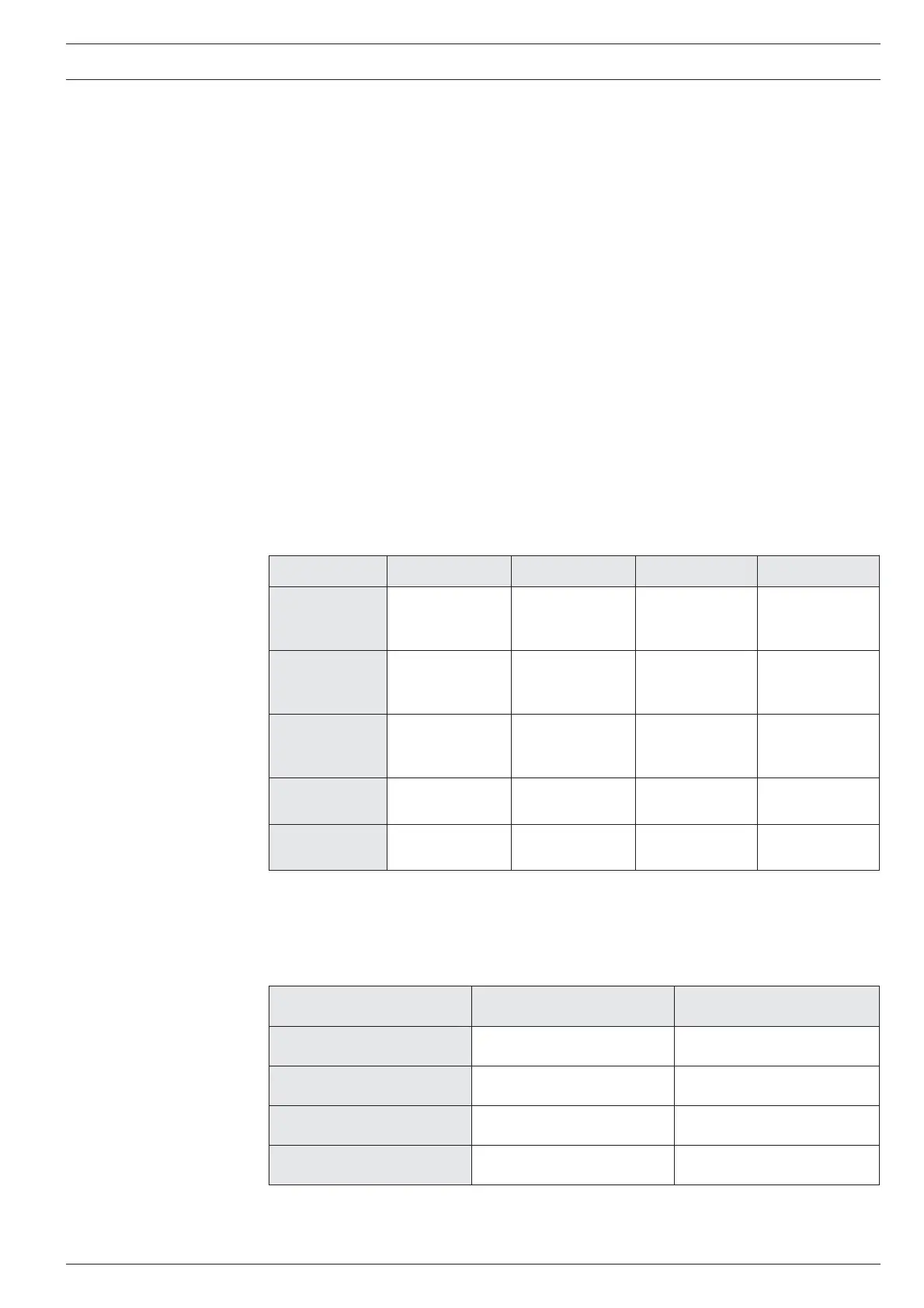

14.5 Electrical Data

Version: 100 - 230 V ± 10 %, 50/60 Hz

CA/V032-001stnairaV 07ML/ammag 58ML/ammag

:gnitarrewoPW71W22

:tnerrucdetaRA7.0A1

:tnerruckaepnohctiwS)sm1.xorpparof(A51)sm1.xorpparof(A51

:esuFTA8.0TA8.0

Note Fuses must display VDE, UL and CSA certification, e.g. type 19195 from Wickmann in

accordance with IEC publication 127 - 2/3

Loading...

Loading...