13 Fundamentals on wo rking with the machine

30 of 54

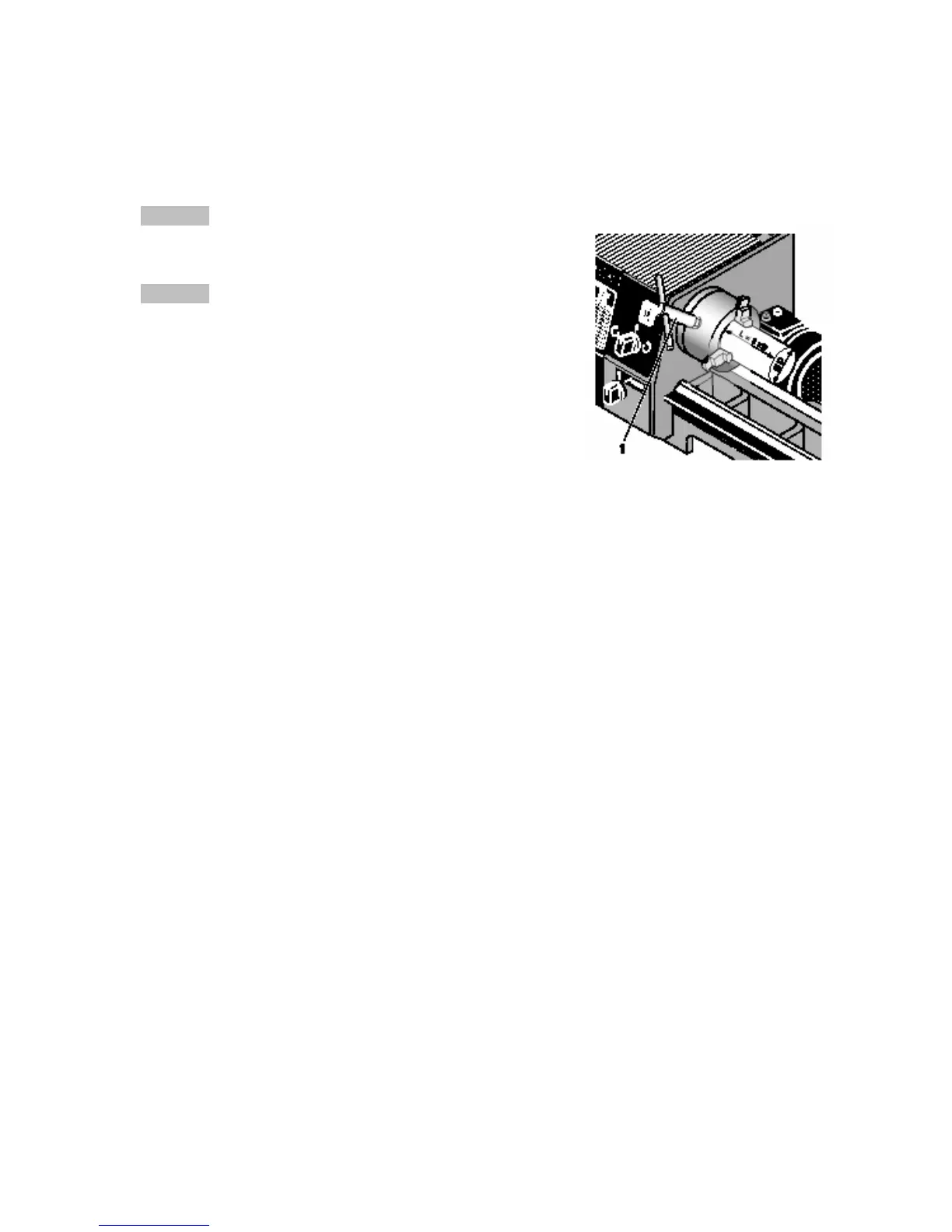

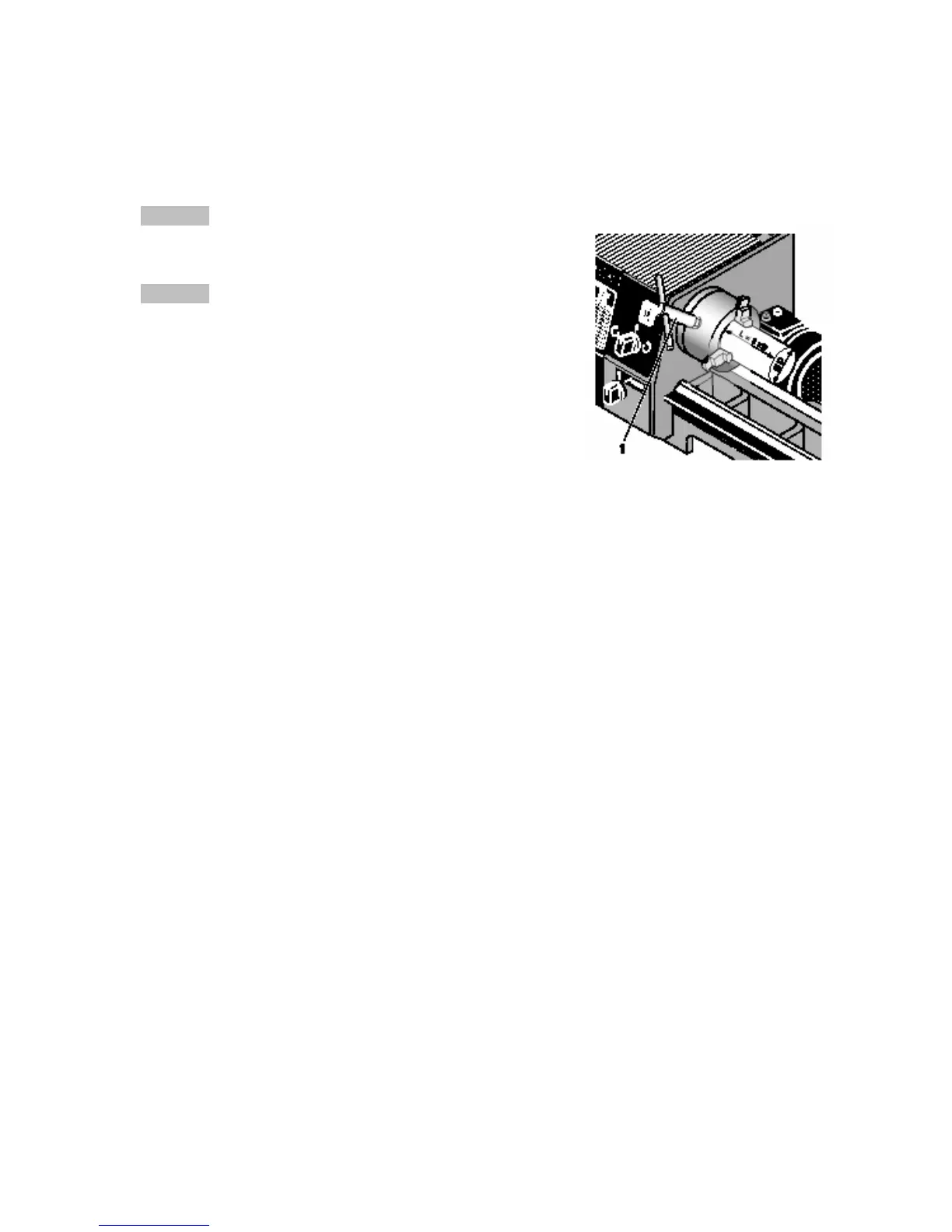

13.6. Clamping in the lathe chuck

Caution!

Please comply with the enclosed operating instructions of

the chuck manufacturer as necessary!

Caution!

If work pieces are only clamped in the lathe chuck

without counter-bracket by the tailstock, the projection

may not be greater than the three-fold diameter of the

material (L = 3 x D), see figure at right.

13.7. Determining the correct spindle speed

The cutting speed is a decisive parameter during machining. Too high or too low cutting

speeds affect the good end result, so the choice of spindle speed – which is decisive for

the cutting speed – is very important for a good surface and clean metal removal.

Another determining factor is the diameter of the work piece: the greater it is, the greater

the relative speed is at the circumference at constant speed. The relation is

characterised by the following equation:

n = Vc * 1000/ (D * 3.14)

whereby:

n: Rotational speed

Vc: Cutting speed

D: Diameter

The table on the gear case of the machine offers help in choosing the right cutting

speed. For known cutting speed "Vc" and known work piece diameter "D", the necessary

spindle speed "n" can be calculated.

An example:

An aluminium work piece with a 30mm diameter will be machined. The necessary

cutting speed according to the table is 100–180m/min. We will calculate 132m/min.

n = 132 x 1000/ (30 x 3.14) = 1400 rev/min

This result can be read directly in the table on the gear case.

Loading...

Loading...