SECTION 3 - RIGGING, HANDLING AND STORAGE

QUANTECH

27

FORM QTC4-NM1

ISSUE DATE: 4/2/2018

3

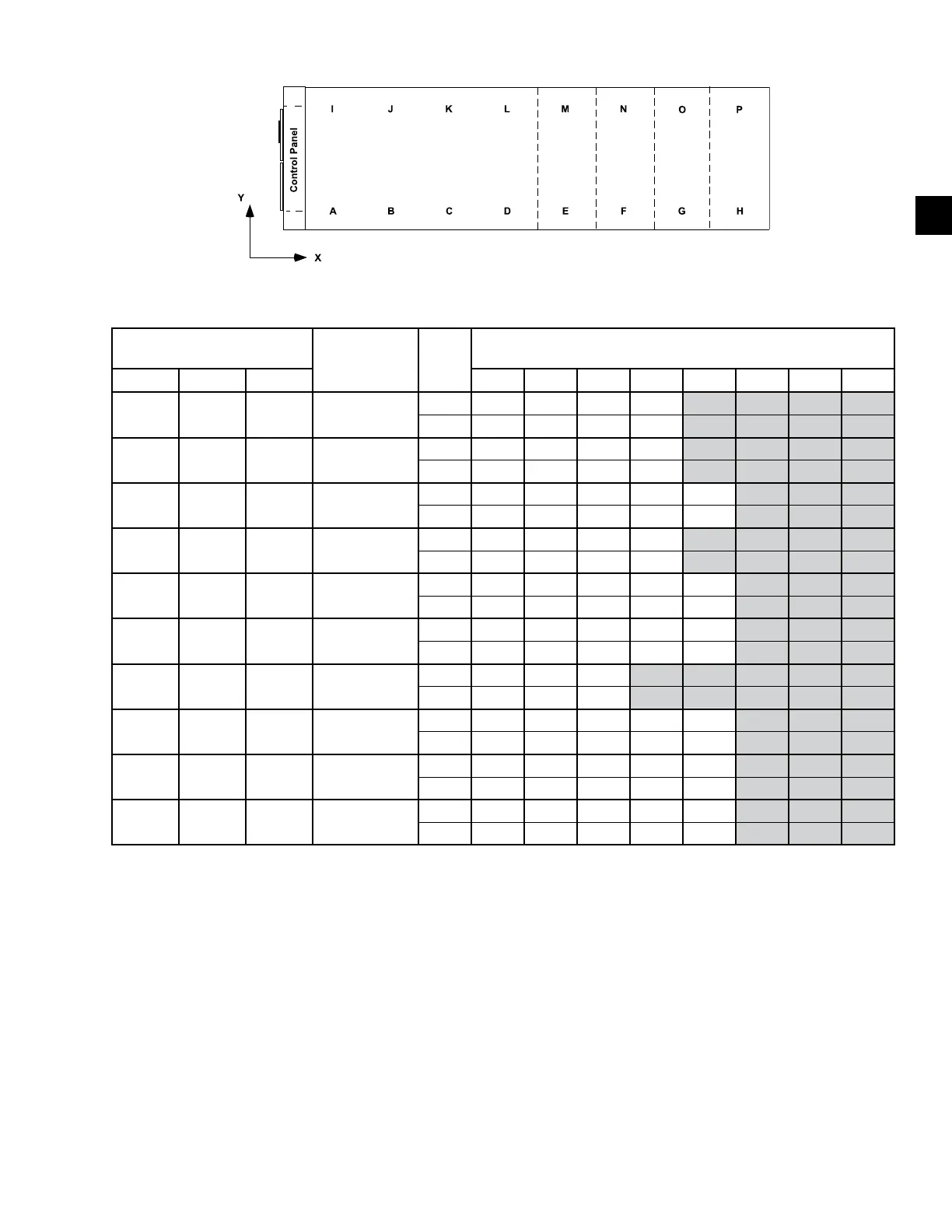

TABLE 1 - UNIT RIGGING (CONT'D)

LD18582

QTC4 MODEL

DESCRIPTION UNITS

RIGGING HOLES

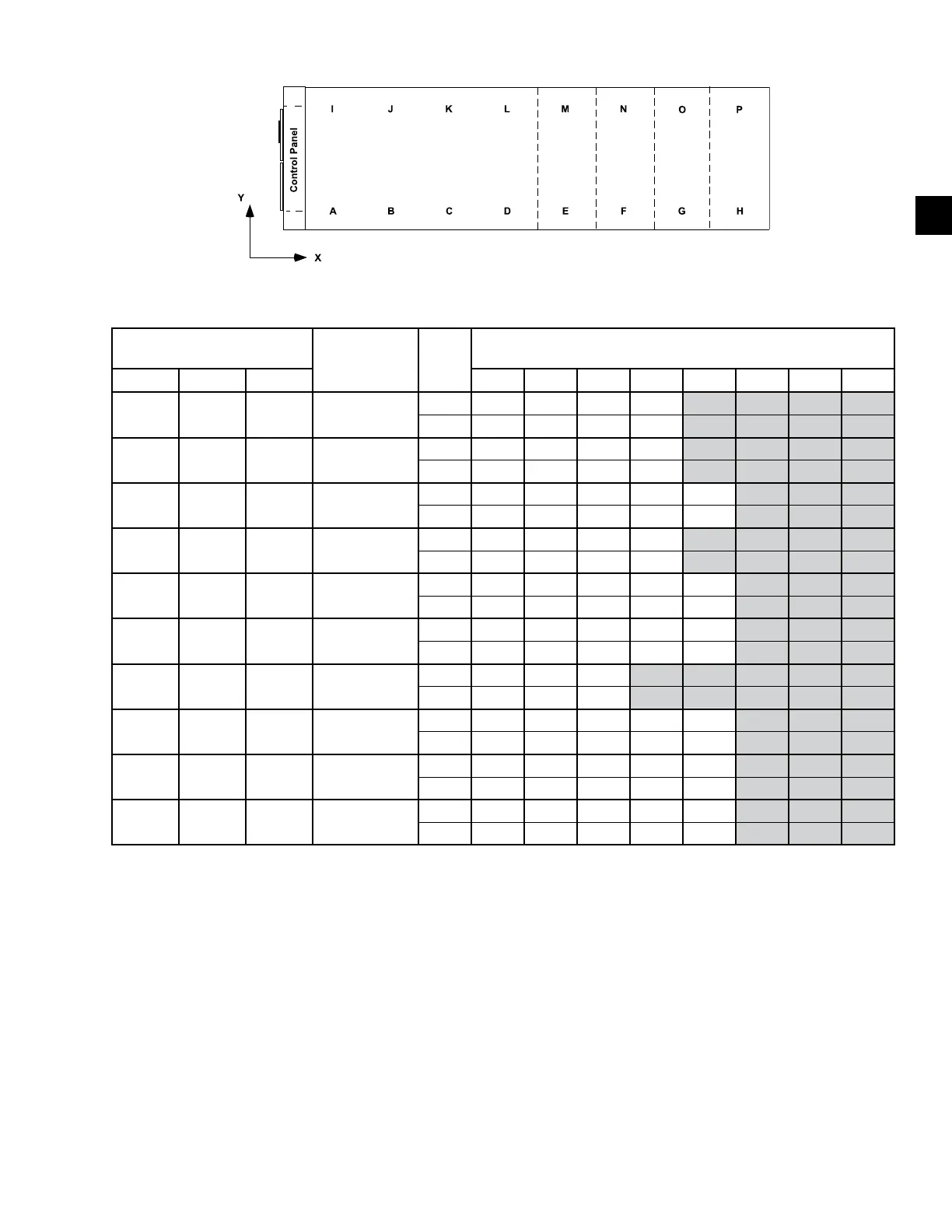

MODEL COND EVAP I J K L M N O P

150 S B

Rigging Hole

Location

inches 18 60 116 192

mm 464 1511 2937 4866

165 H B

Rigging Hole

Location

inches 18 60 137 214

mm 464 1533 3485 5435

175 P C

Rigging Hole

Location

inches 12 73 144 197 260

mm 314 1845 3654 5012 6593

185 S A

Rigging Hole

Location

inches 18 60 143 220

mm 464 1533 3636 5598

185 H A

Rigging Hole

Location

inches 18 60 143 227 272

mm 464 1533 3636 5761 6920

185 P B

Rigging Hole

Location

inches 18 60 137 215 302

mm 464 1533 3484 5455 7670

175 C C

Rigging Hole

Location

inches 60 131 214

mm 1518 3332 5430

210 S A

Rigging Hole

Location

inches 18 60 143 227 272

mm 464 1533 3637 5761 6920

210 H C

Rigging Hole

Location

inches 12 73 144 197 260

mm 314 1845 3654 5012 6593

210 P C

Rigging Hole

Location

inches 12 73 163 254 324

mm 314 1845 4144 6443 8218

NOTE: Rigging and lifting the unit must be done by a professional rigger safely, as discussed in this section. The rigger should locate the center

of gravity through trial lifts to account for possible variations in unit conguration. Contact your nearest Quantech Sales Ofce for weight data.

Loading...

Loading...