ADAPTER INSTALLATION PROCESS

OM 0495SB-A [57]

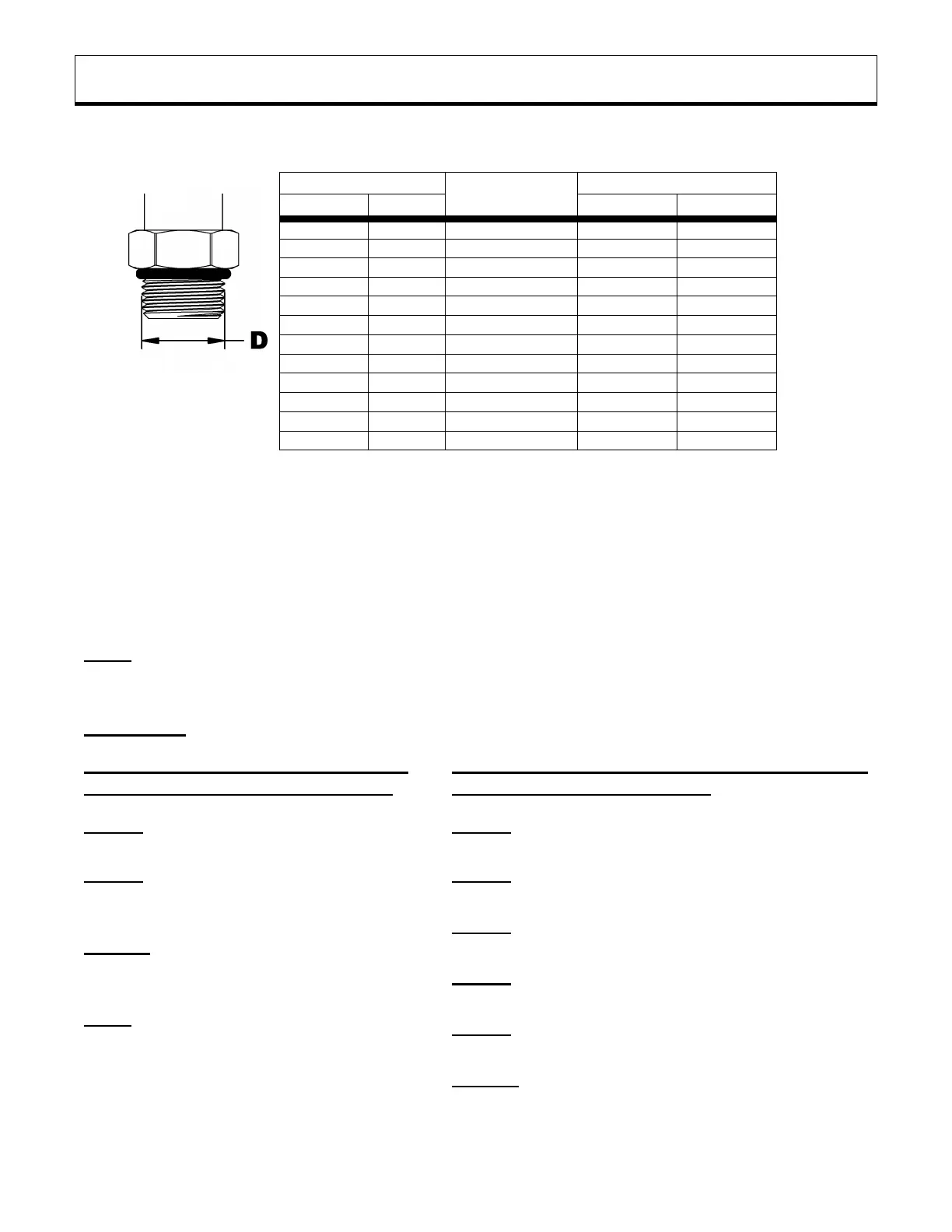

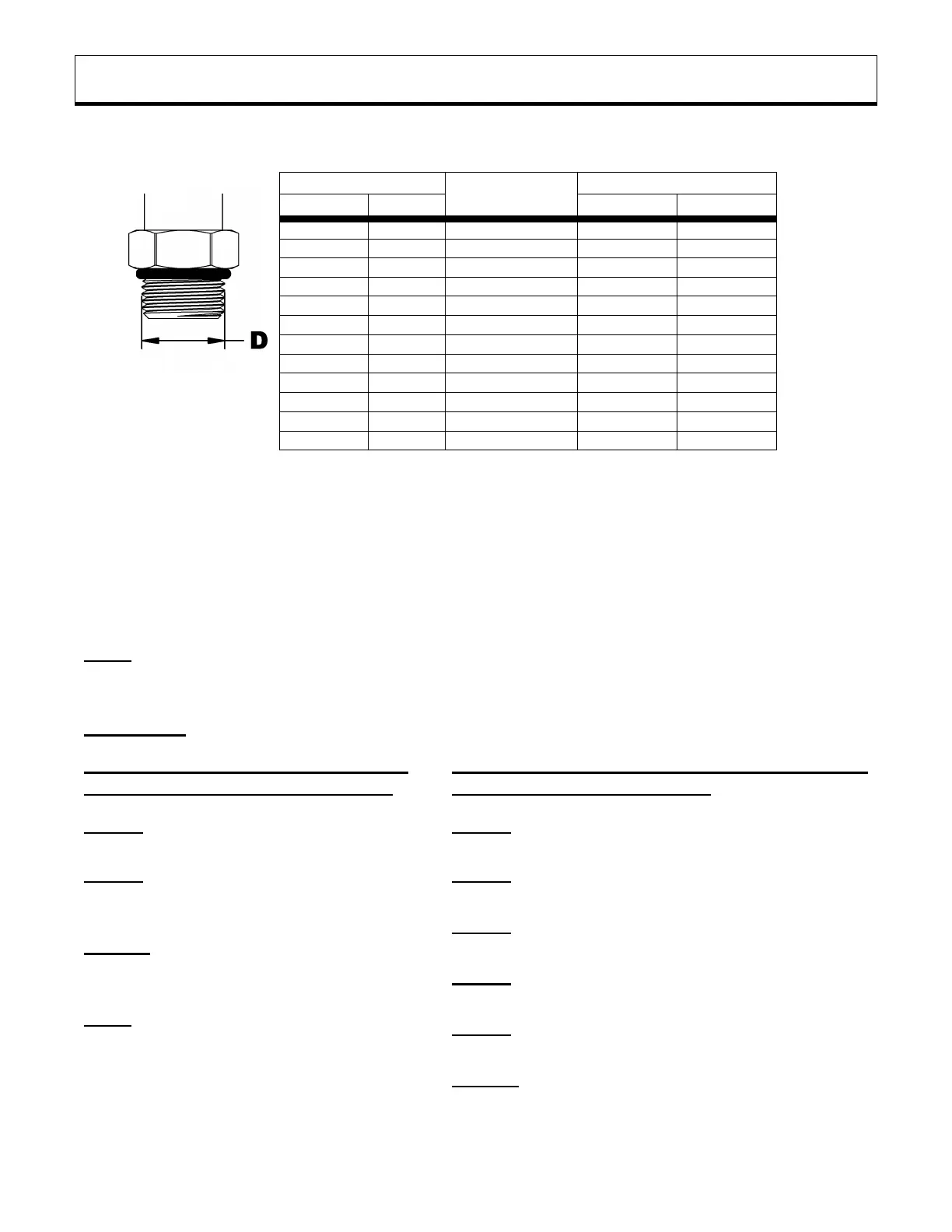

ORB (O-RING BOSS) THREAD IDENTIFICATION & TORQUE

SAE O-rings (O-Ring Boss) are straight thread fittings that seal using an O-ring between the thread and

the wrench flats of the fitting. The O-ring seals against the machined seat on the female port.

O-ring fittings can be either adjustable or non-adjustable. Non adjustable fittings are screwed into a port

where no alignment is needed. Adjustable fittings can be oriented in a specific direction.

Fittings with O-rings offer advantages over metal-to-metal fittings. Under or over-tightening any fitting can

allow leakage, but all-metal fittings are more susceptible to leakage because they must be tightened to a

higher and narrower torque range. This makes it easier to strip threads or crack or distort fitting

components, which prevents proper sealing.

NOTE: Do not apply thread sealant (teflon tape) on the ORB threads.

Leaks can also result from vibration, thermal cycling and from loads being supported by the connection

(i.e. using the fitting in the connection to support mechanical loads).

IMPORTANT: Use the lowest torque value from the chart when wet torquing.

RECOMMENDED ASSEMBLY

ORB (O-RING) NON-ADJUSTABLE

STEP 1: Inspect all components for

damage or contamination.

STEP 2: Lubricate O-ring and threads on

fitting with the same hydraulic fluid used in the

tractor.

STEP 3: Turn fitting into port until finger tight,

then torque to the value shown in the

following table.

NOTE: Use the lowest torque value from

the chart when wet torquing.

RECOMMENDED ASSEMBLY

ORB (O-RING) ADJUSTABLE

STEP 1: Inspect all components for damage or

contamination.

STEP 2: Lubricate O-ring and threads on fitting with the

same hydraulic fluid used in the tractor.

STEP 3: Looking at fitting from the male ORB end, turn

manually the nut as far as possible from the O-ring.

STEP 4: Using wrench, turn fitting into port until the

washer touches thread nearest wrench pad.

STEP 5: Back off• fitting counterclockwise not exceeding

one revolution until it is oriented in the correct position.

STEP 6 : Place wrench on the wrench pad of fitting to

prevent fitting from turning, and torque nut to the value

shown in the above table.

Loading...

Loading...