LIFTLOG 1000 – INSTALLATION AND CALIBRATION

14

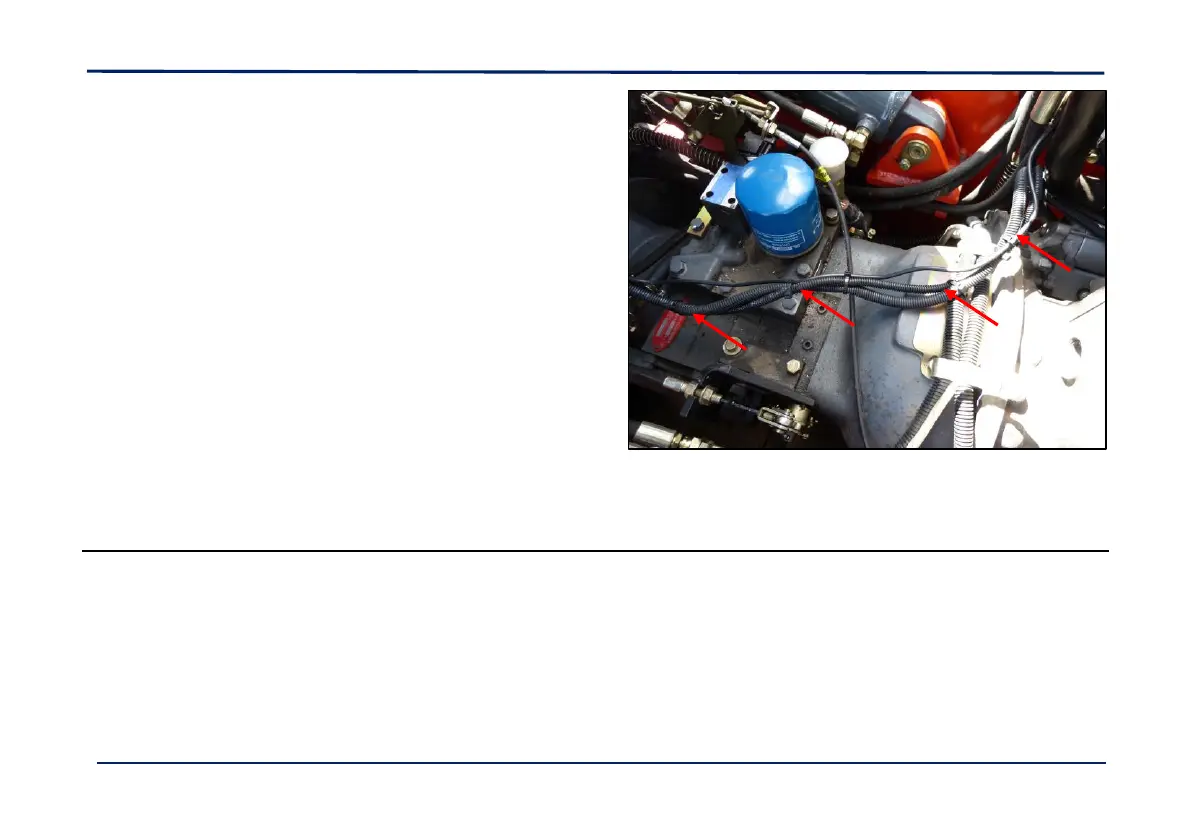

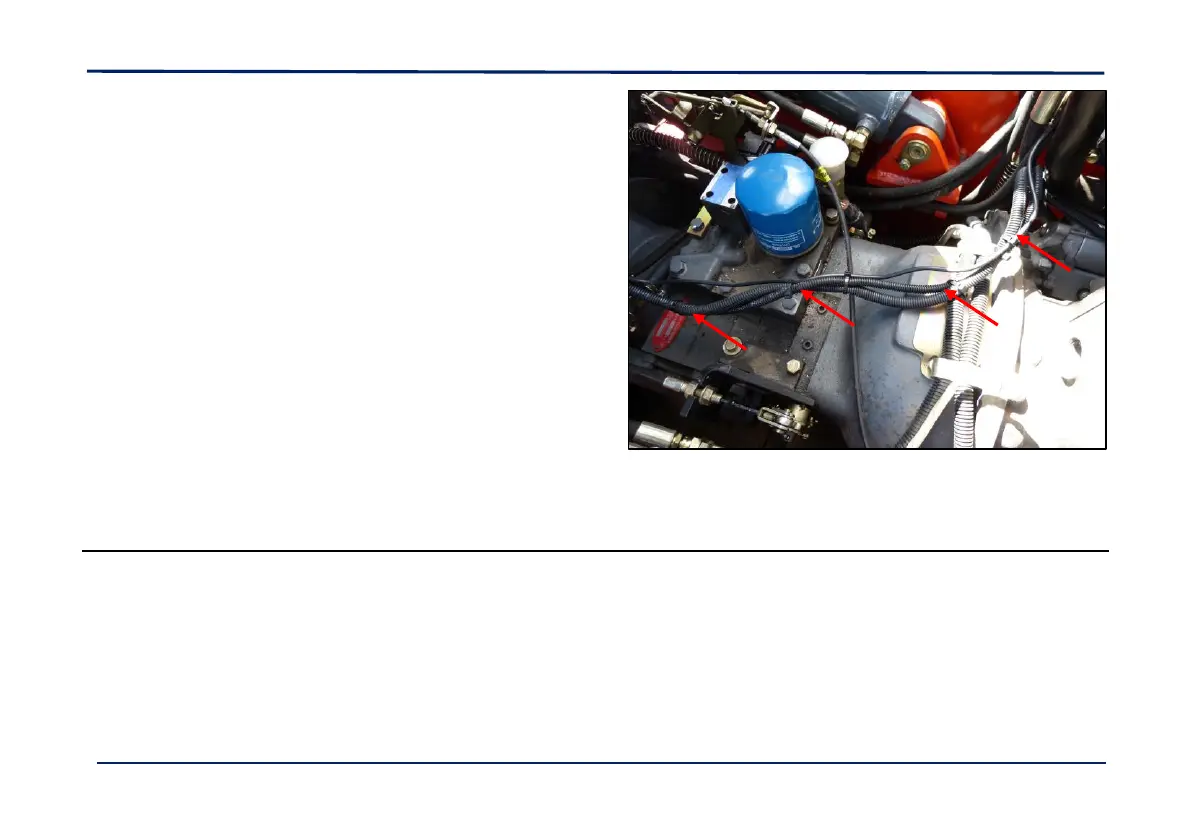

Route the pressure sensor lead and solenoid lead back to

the Terminator.

Cable tie at regular intervals following the existing wiring

loom where possible.

Ref. 2.4.4 for wiring connections.

2.1.1 Flow Rate Adjustment

The drop rate may need to be adjusted depending on the particular machine. With the solenoid connected and the head unit

powered up, press the weigh button to energize the solenoid and observe the rate of drop. Slacken the locking nut and turn the

adjuster screw in or out to decrease or increase the drop rate (i.e. approximately 15cm or 6” over the 5 second sampling period).

NOTE: Drop rate can be set with empty forks, since the drop valve keeps the flow rate constant under varying pressure.

Loading...

Loading...