11-01

680 High Clearance Sprayer - Operation Instructions

Section B

4

Section B

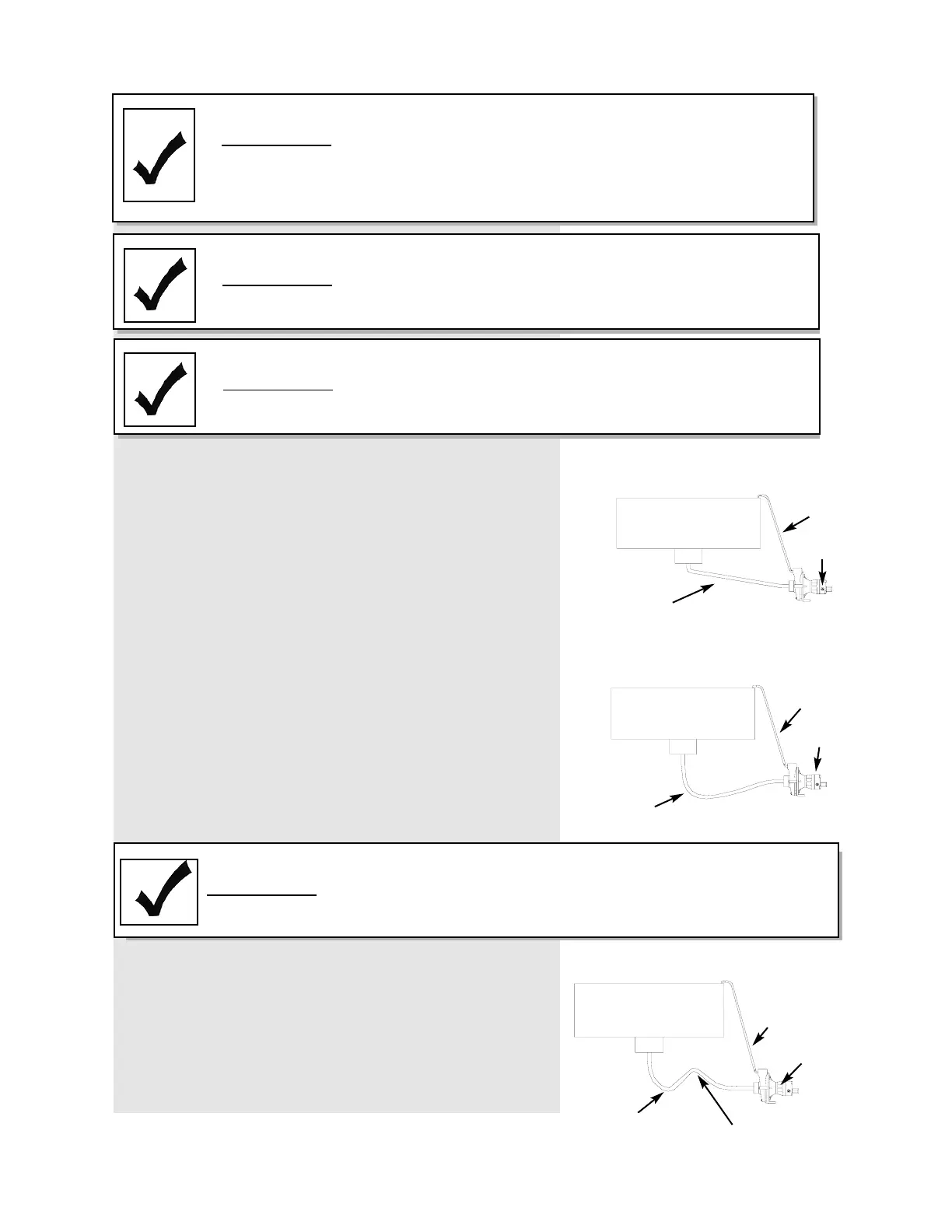

A “Flooded” condition is when the centrifugal pump is

completely full of fluid and no pockets of air are present

in the pump. In order to get maximum pump efficiency

the mounting and plumbing must meet the guidelines

stated below.

1. The pump inlet must be mounted below the product

tank(s) sump to allow gravity to naturally fill the

pump with liquid. See Figures 1 - 3.

2. The suction line must have a continual rise from the

pump inlet to the tank sump.

3. The pump must have the vent line plumbed to it.

It is very important that the proper oil flow is supplied to

the hydraulic motor which powers the pump. Excessive

flow will over-speed the motor and cause motor damage.

To regulate the correct oil flow to the pump motor

see the pump manufacturer’s manual.

Hydraulically Driven Diaphram Pump

Follow the pump manufacturer’s instructions for opera-

tion.

Product Tank

Vent

Line

Suction Line

Acceptable

Pump

Figure 2

Product Tank

Vent

Line

Air Trap Point

Pump

Figure 3

Suction Line

Not Acceptable

IMPORTANT

There are two basic rules to follow when operating a hydrauli-

cally driven centrifugal pump:

1. Never run the pump in a “Non-Flooded” condition.

2. Always have the correct oil flow to the pump motor.

Always read and follow the pump manufacturer’s opera-

tional instructions.

IMPORTANT

The Vent Line is designed to prevent air lock by bleeding off

trapped air. This allows the pump to prime and keeps some

fresh solution circulating by the seal.

IMPORTANT

For proper venting, the vent line must continually rise from the

pump to the top of the tank. Any drop or downward routing

will significantly depreciate its venting capabilities and render it

useless for its intended purpose.

IMPORTANT

Turn off a hydraulically driven centrifugal pump using the “float” posi-

tion of the tractor’s hydraulic valve. This allows the motor to stop

slowly helping to protect the motor and motor seals.

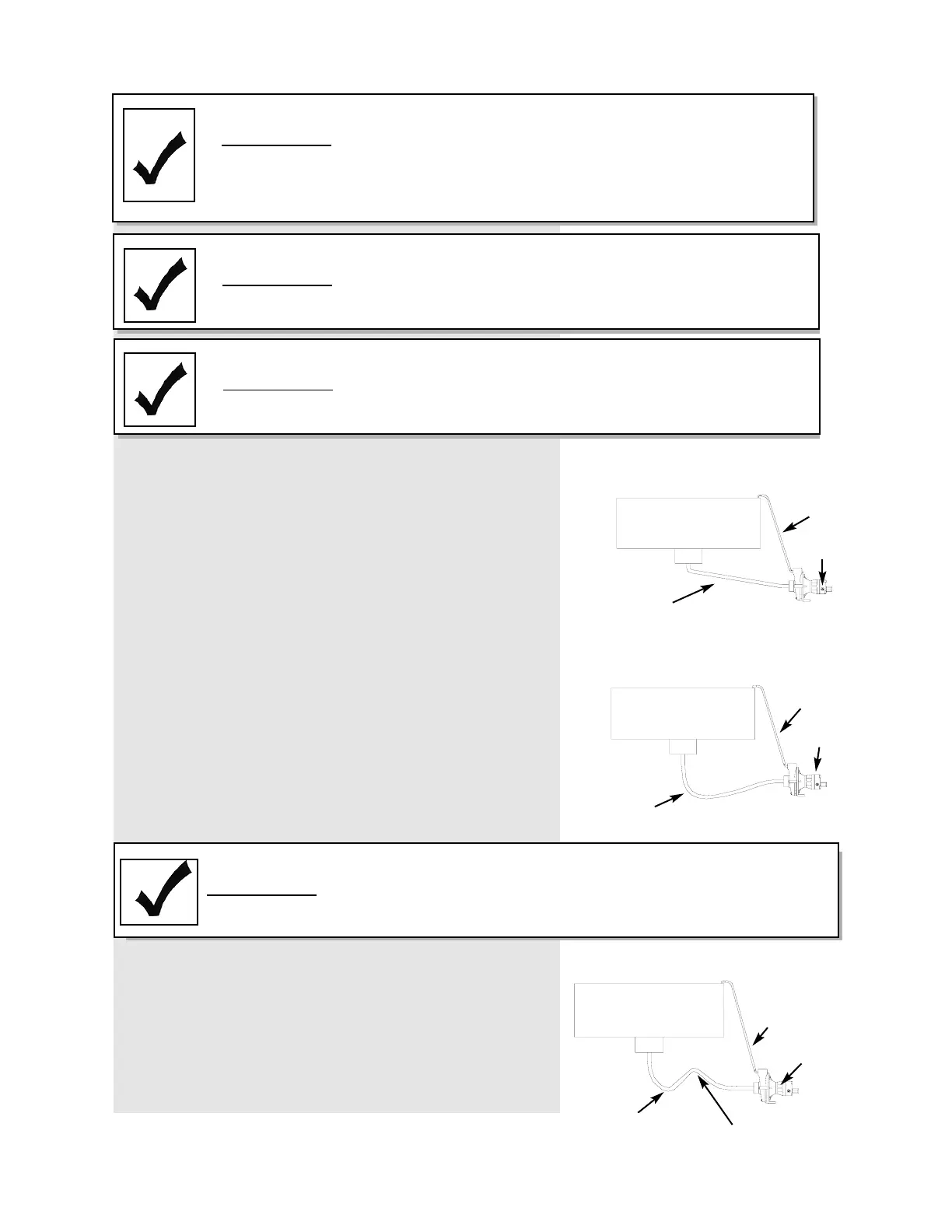

Product Tank

Vent

Line

Suction Line

Ideal

Pump

Figure 1

Loading...

Loading...