11-01

Axles

Fixed Row Crop Width Axles

The Redball

®

Model 680 High Clearance Sprayer has an

option of fixed axles. These axles are ordered at a pre-

set width and are not adjustable.

Adjustable Row Crop Width Axles

The Redball

®

Model 680 High Clearance Sprayer has

optional adjustable axles which allow the operator to

increase or decrease the width of the spacing between

the tires. Width adjustment will allow for accommodating

different types of crops, which are grown with different

plant row spacings.The procedure for adjusting the axle

width is as follows:

1. Secure sprayer on level ground, assuring NO forward

or aft rolling of sprayer can occur when elevating a

tire.

2. Utilizing a jack, hoist or forklift: raise one side (i.e.

one tire) off the ground.

3. Secure elevated end with jack stands, braces, or

equivalent, assuring the side of the sprayer cannot

fall, causing a hazard to personnel under the sprayer.

4. The axle tube is very heavy and should only be

moved with the aid of a floor jack or equivalent

lifting system. Loosen the four U-bolts located

along the axle cross frame and slide the spindle and

hub assembly to the new desired width setting. If any

of the axle adjustment u-bolts need to be complete

ly removed, extreme care should be taken to assure

the axle tube weldment is not dropped. Tires should

always be placed equal distance from the trailer center

line, as an offset may cause poor trailing stability.

5. Tighten all axle adjustment bolts to the torque

specified in section E. Replace any bolts or nuts

that have signs of physical damage, especially noting

damage due to corrosion.

6. Remove jack stands/braces and lower unit back

to the ground.

7. Repeat for the other side making certain the

same distance from the centerline is achieved.

Never attempt to adjust the tire width unless the sprayer is

secure, and on level ground. The liquid tank should be

completely void of fluid. Always secure sprayer with jack

stands, braces or equivalent when working under an

elevated unit.

DANGER

Do not exceed the following settings, which

are dependent on the particular sprayer

axle configuration purchased.

Overall

Axle Width (Inch) 8 Bolt Hub

Configuration

Minimum Maximum Axle Length

Option 1 62” 80” 52”

Option 2 80” 120” 71”

Option 3 120” 152” 110”

2

Section C

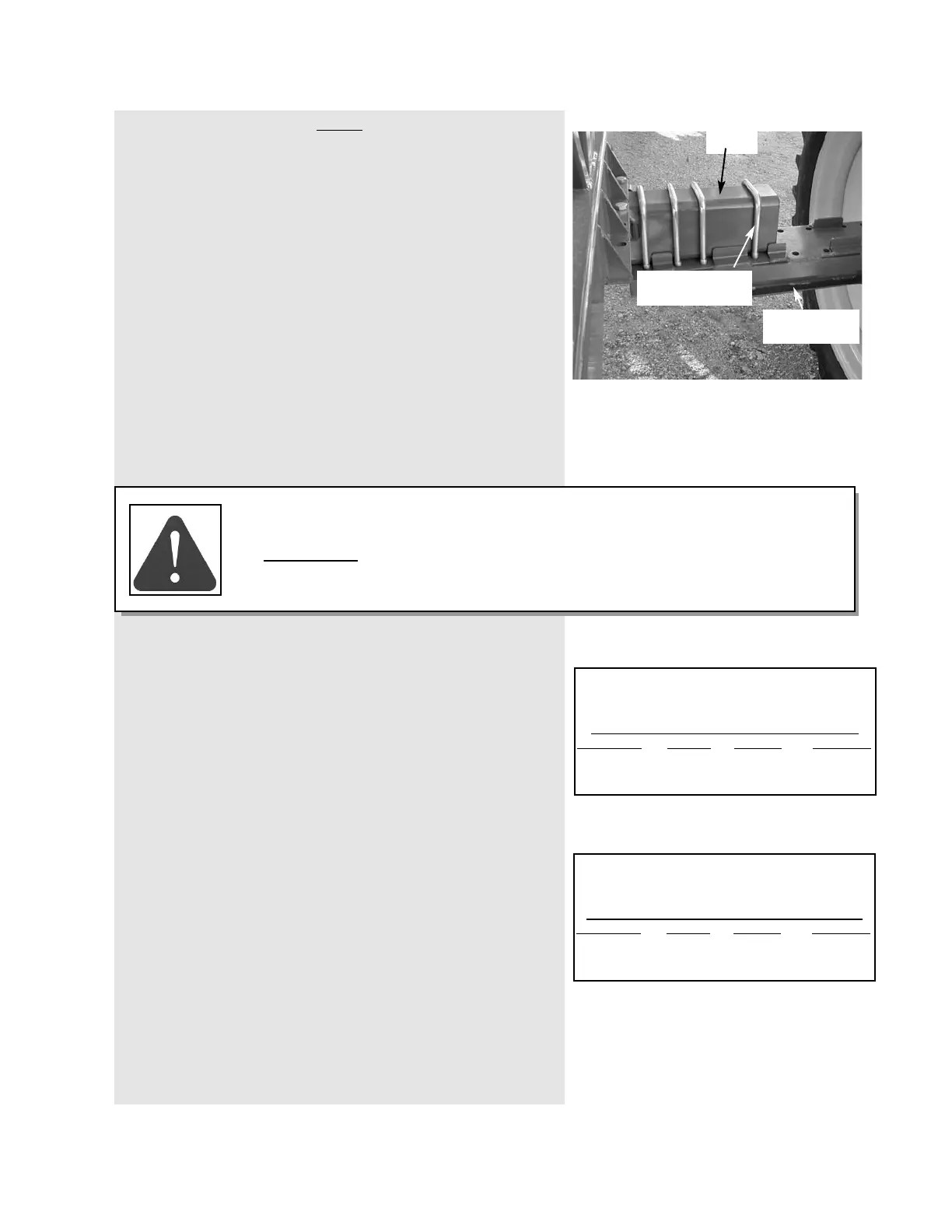

Axle Tube Weldment

Do not exceed the following settings, which

are dependent on the particular sprayer

axle configuration purchased.

Overall Axle Width (Inch) 10 Bolt Hub

Configuration Minimum Maximum Axle Length

Option 1 62” 80” 56 1/2”

Option 2 80” 120” 74 1/2”

Option 3 120” 152” 114 1/2”

680 High Clearance Sprayer - Connection & Startup

Section C

Axle

Axle Adjustment

U-Bolts

Spindle Hub

Assembly

Loading...

Loading...