11-01

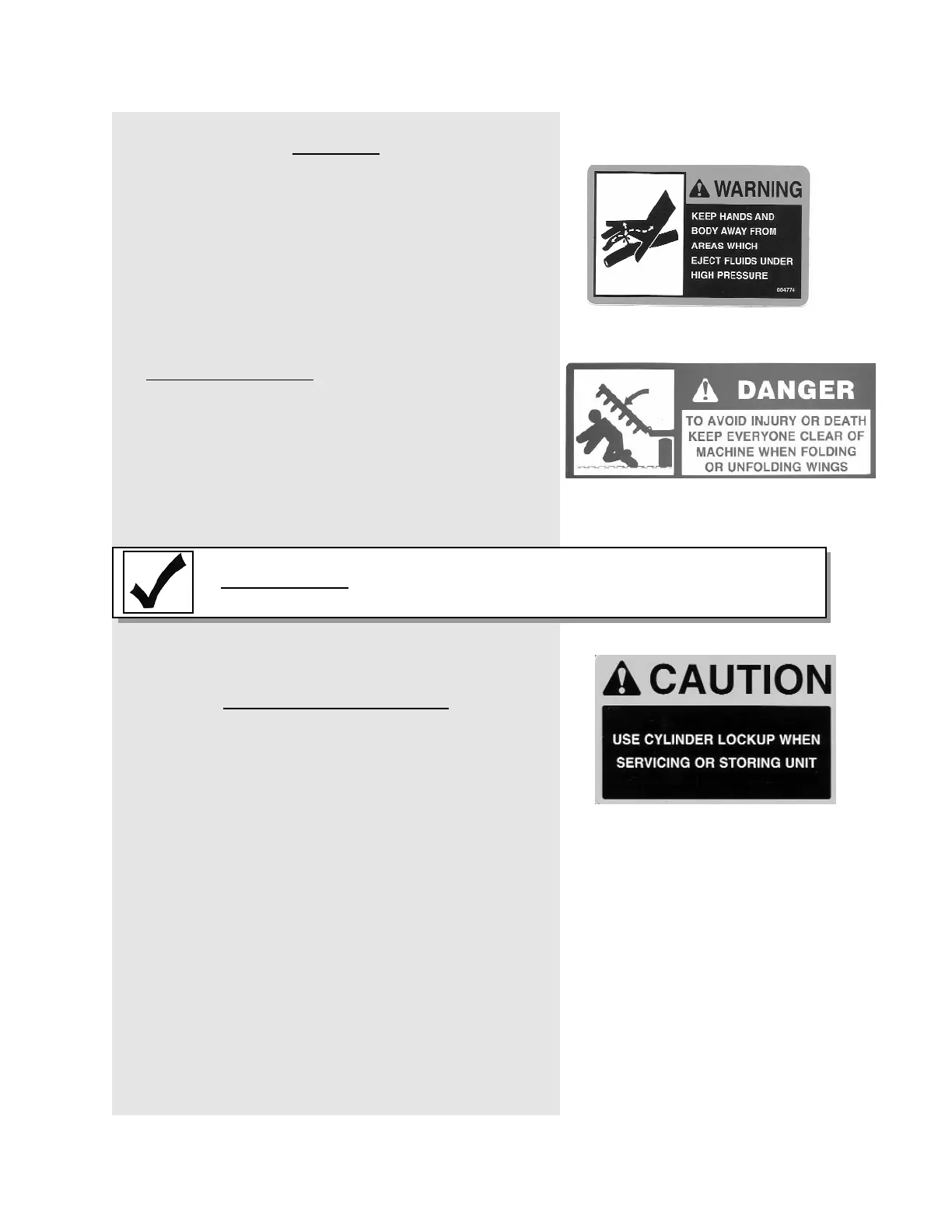

Hydraulics

1. Inspect cylinder shafts for corrosion or damage.

Repair or replace shaft to avoid hydraulic leaks or

cylinder failure.

2. Inspect hydraulic hoses. Replace any hose that

shows signs of wear or damage.

3. Removing hydraulic hoses for any reason requires

that you plumb them back to their original position.

Failure to do this may result in incorrect operation

and may damage the sprayer. Refer to Section F,

Part

s and Schematics for a hydraulic plumbing dia-

gram.

Electrical & Control System

Use of dielectric grease is strongly urged for all electrical

wire connections. All connections should be greased at

the beginning of the season. Poor electrical connections

due to corrosion is the leading cause of failure of sprayer

equipment in this environment.

Packard style connections on certain options are

designed to be weather resistant. This feature greatly

reduces the corrosion associated with electric connec-

tors. Use of dielectric grease is optional on these con-

nections.

680 High Clearance Sprayer - Maintenance, Service &

Troubleshooting

Section E

2

Section E

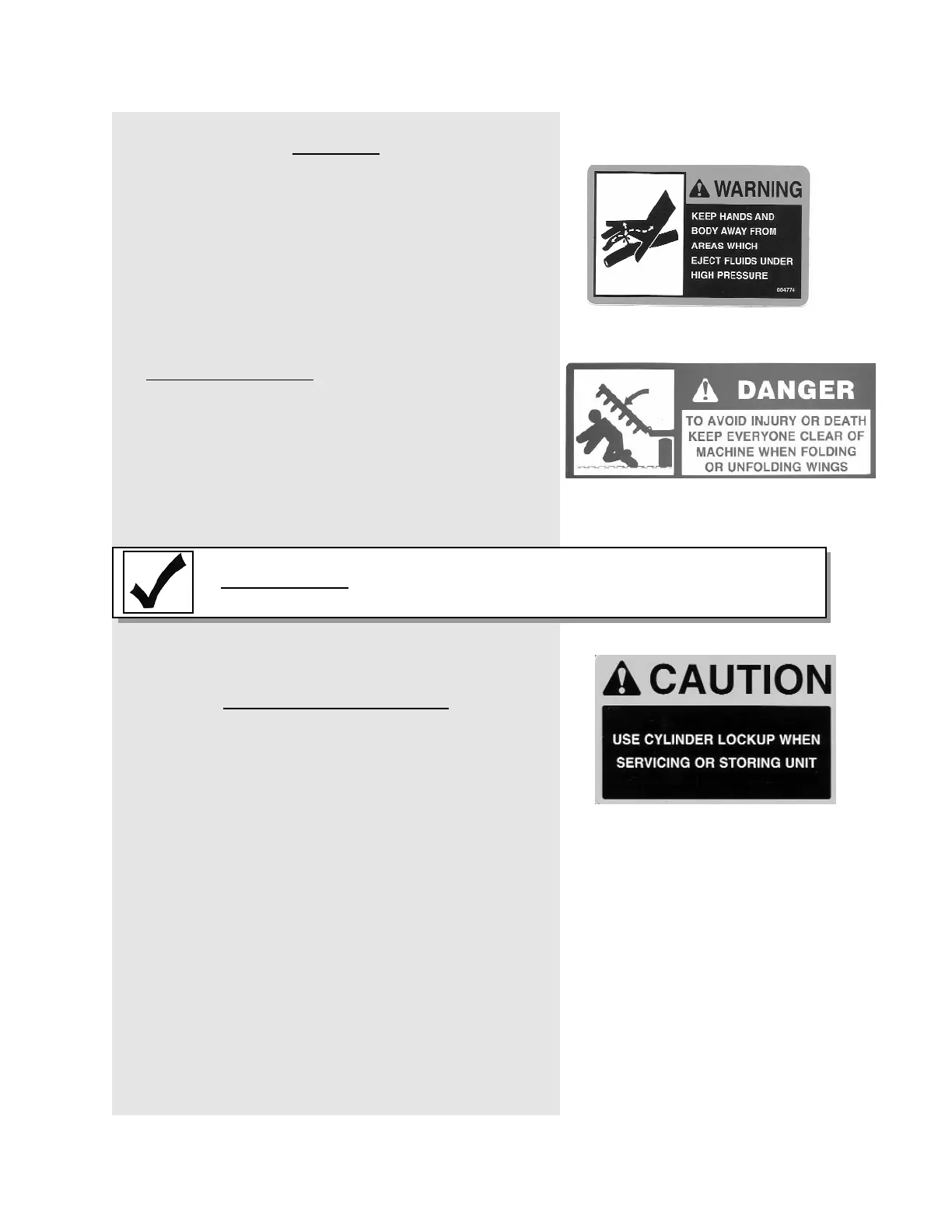

Failure to plumb the parallel cylinders correctly may cause

damage to the henschen suspension.

IMPORT

ANT

Loading...

Loading...