2-6

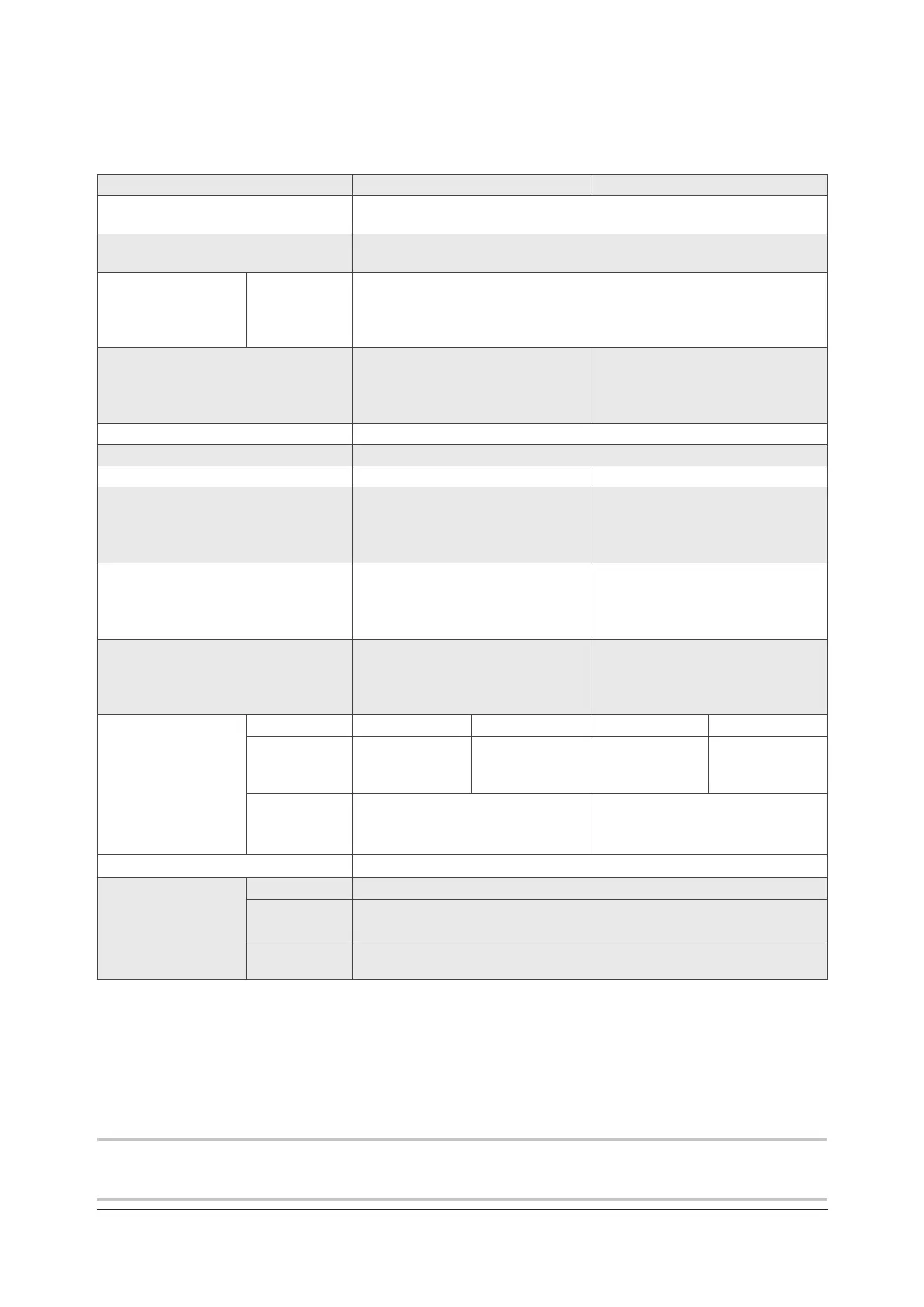

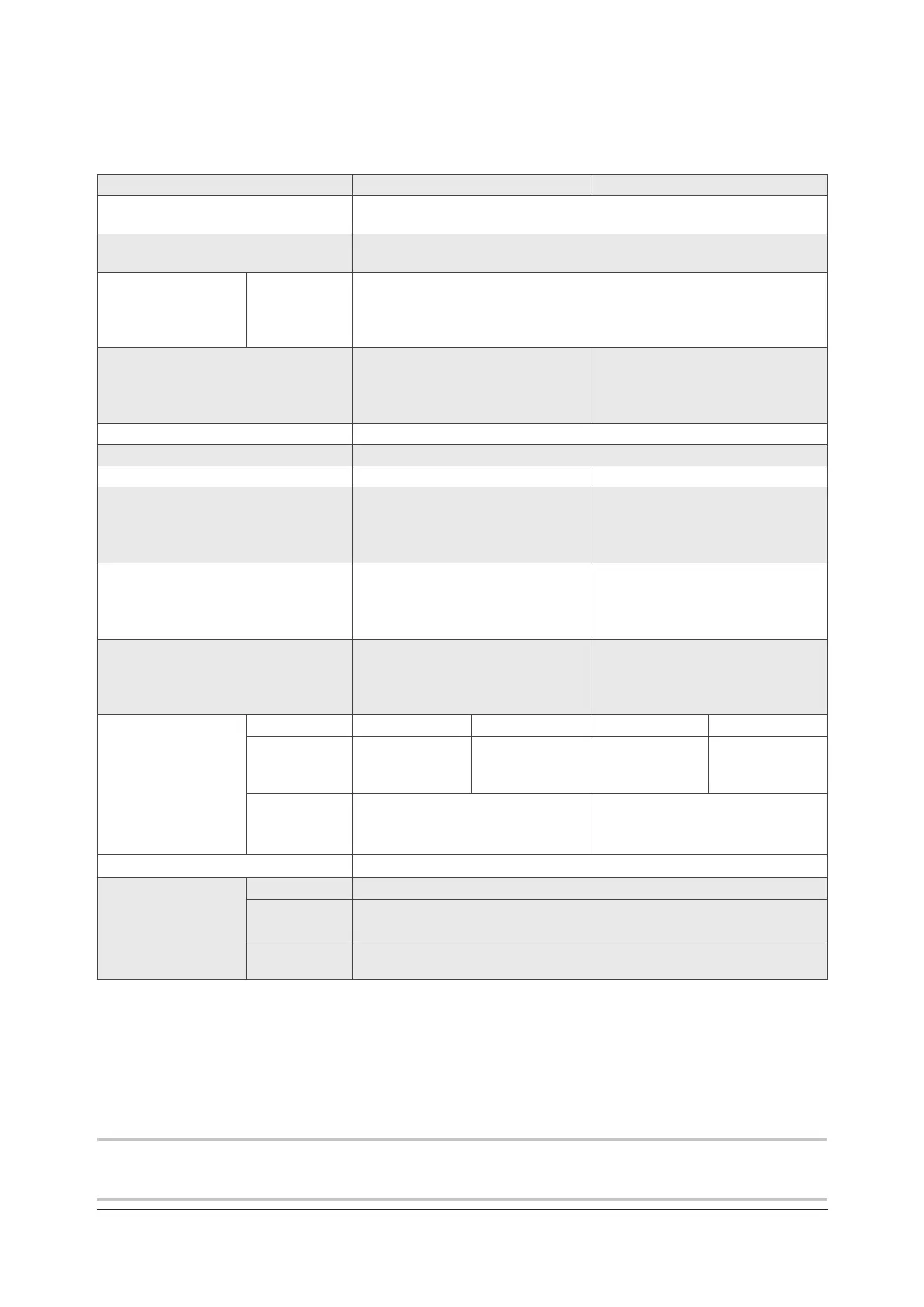

LP2 probe system: LP2 basics

Variants LP2 / LP2DD LP2H / LP2HDD

Principal application Workpiece inspection and job set-up on all sizes of lathes,

machining centres and CNC grinders.

Transmission type Hard-wired, or in conjunction with optical or radio transceiver

modules

Compatible

interfaces

Hard-wired

Optical

Radio

HSI, HSI-C, MI 8-4, FS1i or FS2i

OMI-2 / OMI-2T / OMI-2H / OSI or OSI-D with OMM-2 or OMM-2C

RMI-Q / RMI-QE

Recommended styli

50 mm (1.97 in) to 100 mm

(3.94 in)

Stylus material depends on

application.

50 mm (1.97 in) to 150 mm

(5.91 in)

Stylus material depends on

application.

Weight 65 g (2.29 oz)

Sense directions ±X, ±Y, +Z

Unidirectional repeatability 1.00 μm (40 μin) 2s

1

2.00 μm (80 μin) 2s

1

Stylus trigger force

2 3

XY low force

XY high force

+Z direction

0.50 N, 51 gf (1.80 ozf)

0.90 N, 92 gf (3.24 ozf)

5.85 N, 597 gf (21.04 ozf)

2.00 N, 204 gf (7.19 ozf)

4.00 N, 408 gf (14.39 ozf)

30.00 N, 3059 gf (107.91 ozf)

Maximum setting:

XY low force

XY high force

+Z

1.00 N, 102 gf (3.59 ozf)

1.85 N, 188 gf (6.65 ozf)

7.40 N, 754 gf (26.61 ozf)

Not applicable

Minimum setting:

XY low force

XY high force

+Z

0.25 N, 25 gf (0.90 ozf)

0.50 N, 51 gf (1.80 ozf)

2.35 N, 239 gf (8.45 ozf)

Not applicable

Stylus overtravel

limits

Variant LP2 LP2DD LP2H LP2HDD

XY plane

14.87 mm

(0.55 in)

±12.5°

19.06 mm

(0.73 in)

±15°

14.87 mm

(0.55 in)

±12.5°

19.06 mm

(0.73 in)

±15°

+Z plane

6.5 mm (0.26 in)

4.5 mm (0.18 in) when tted with

a swarf deector

5.0 mm (0.20 in)

4.5 mm (0.18 in) when tted with

a swarf deector

Mounting

M16 thread, for LPE extension bars and adaptors.

Environment IP rating IPX8, BS EN 60529:1992+A2:2013

Storage

temperature

–25 °C to +70 °C (–13 °F to +158 °F)

Operating

temperature

+5 °C to +55 °C (+41 °F to +131 °F)

Specication

1 Performance specication is tested at a standard test velocity of 480 mm/min (18.9 in/min) with a 35 mm stylus. Signicantly

higher velocity is possible depending on application requirements.

2 Trigger force, which is critical in some applications, is the force exerted on the component by the stylus when the probe triggers.

The maximum force applied will occur after the trigger point (overtravel). The force value depends on related variables including

measuring speed, machine deceleration and latency.

3 These are the factory settings, manual adjustment of the LP2/LP2DD is possible, but not possible on LP2H/LP2HDD.

NOTE: For stylus recommendations, refer to the Styli and accessories technical specications (Renishaw

part no. H-1000-3200).

Loading...

Loading...