5-1

www.renishaw.com/lp2

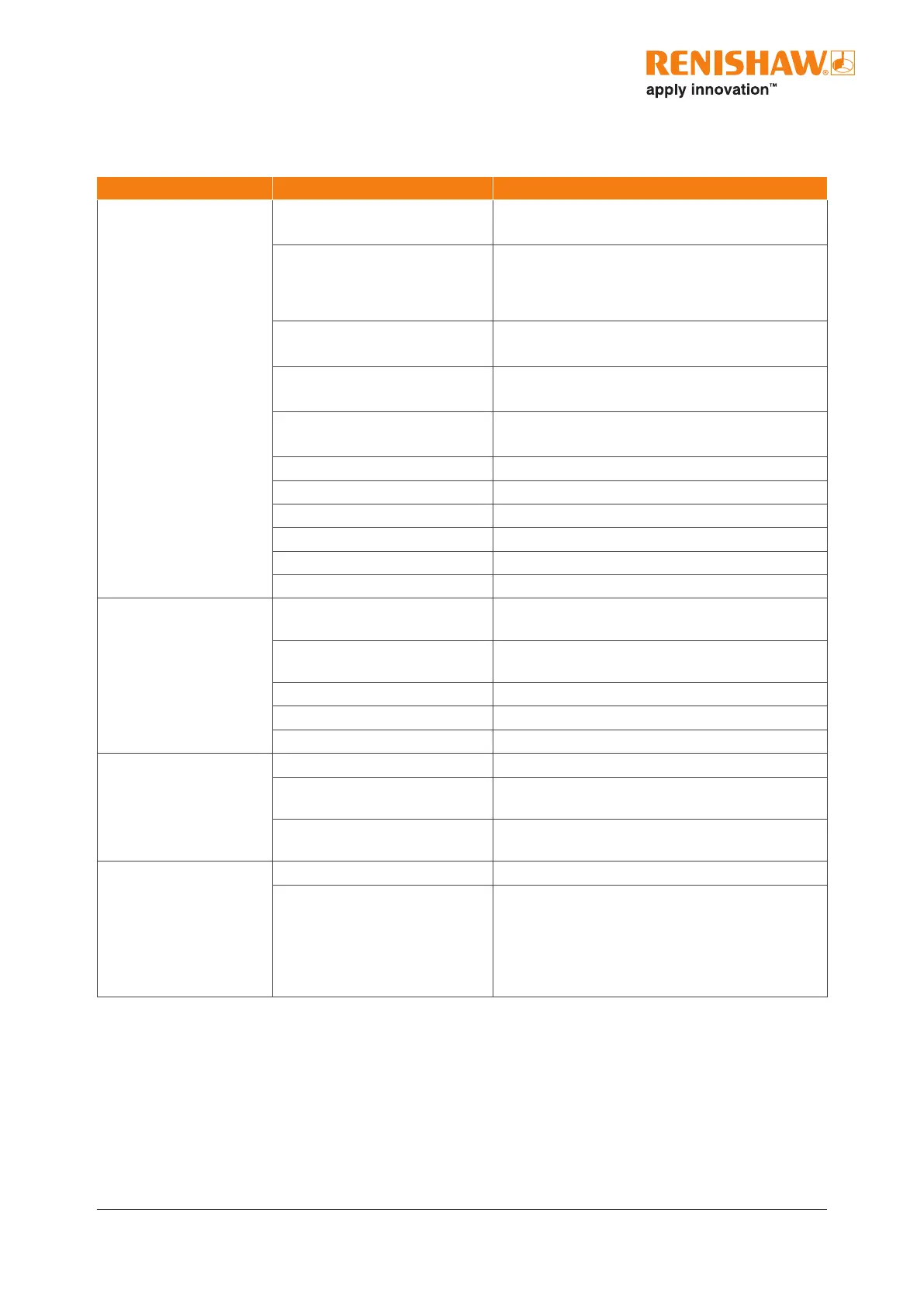

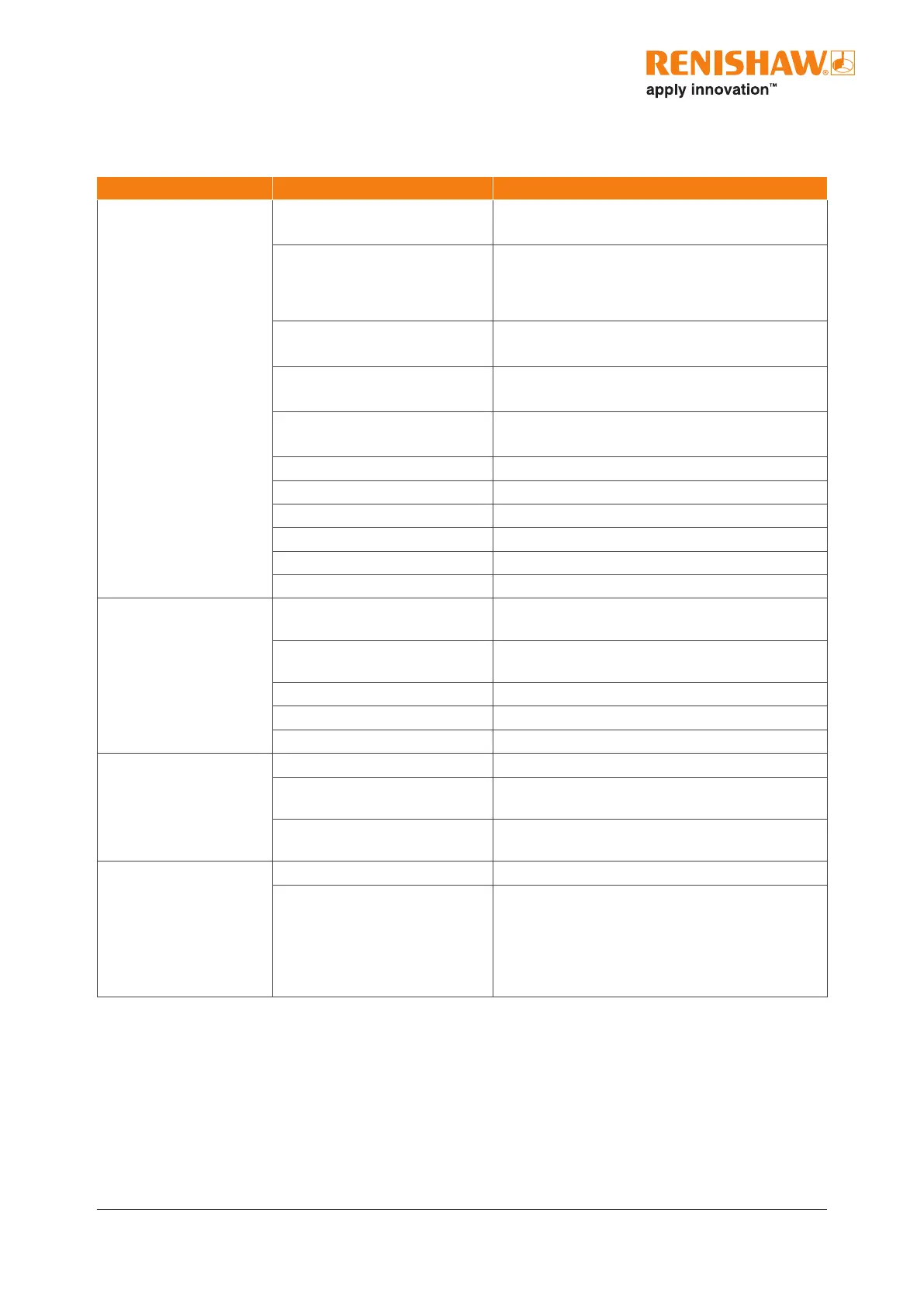

Fault-nding

Symptom Cause Action

Complete failure. Transmission modules not

correctly aligned.

Align correctly.

Transmission modules

damaged.

Return to supplier for repair.

For information on transmission, refer to the

relevant installation guide.

Swarf blocking inductive

transmission air gap.

Clean out.

Loose mounting. Check all bolted or screwed connections for

tightness.

Interface LED does not light

up.

Check fuses.

Poor electrical connection. Check connectors.

Cable screen broken. Replace cable.

Incorrect voltage. Check supply.

Probe failure. No continuity through probe circuit.

Probe spring force too low. Tighten stylus spr

ing force.

Probe mounting damaged. Repair or replace.

Poor repeatability. Transmission modules not

correctly aligned.

Align correctly.

Loose mounting. Check all bolts and screwed connections for

tightness.

Loose stylus. Tighten.

Poor electrical connections. Check connectors.

Excessive machine vibration. Tighten spring force.

Spurious reading. Cab

le screen broken. Replace.

Poorly regulated supply

voltage.

Regulate correctly.

Excessive machine vibration. Eliminate vibration or adjust stylus spring

force.

Poor re-arming (the

probe is armed

when the stylus

mounting is seated,

the electrical circuit

is complete and the

interface LED is lit).

Spring force too low. Adjust spr

ing force.

Inner diaphragm pierced or

damaged.

Return to supplier for repair.

Loading...

Loading...