OMP400 installation guide

3.4

System

installation

MI

1

2

TM

TM

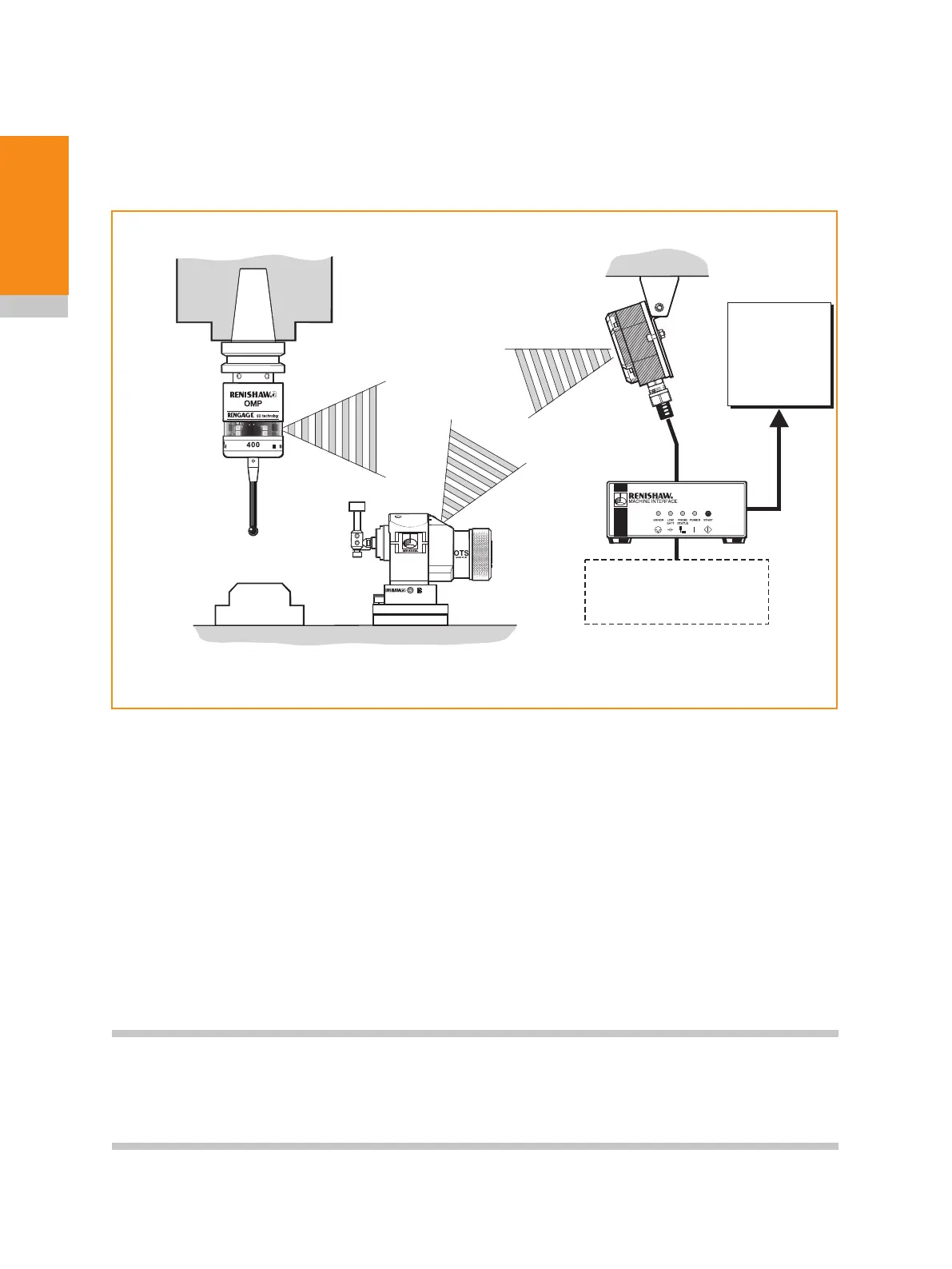

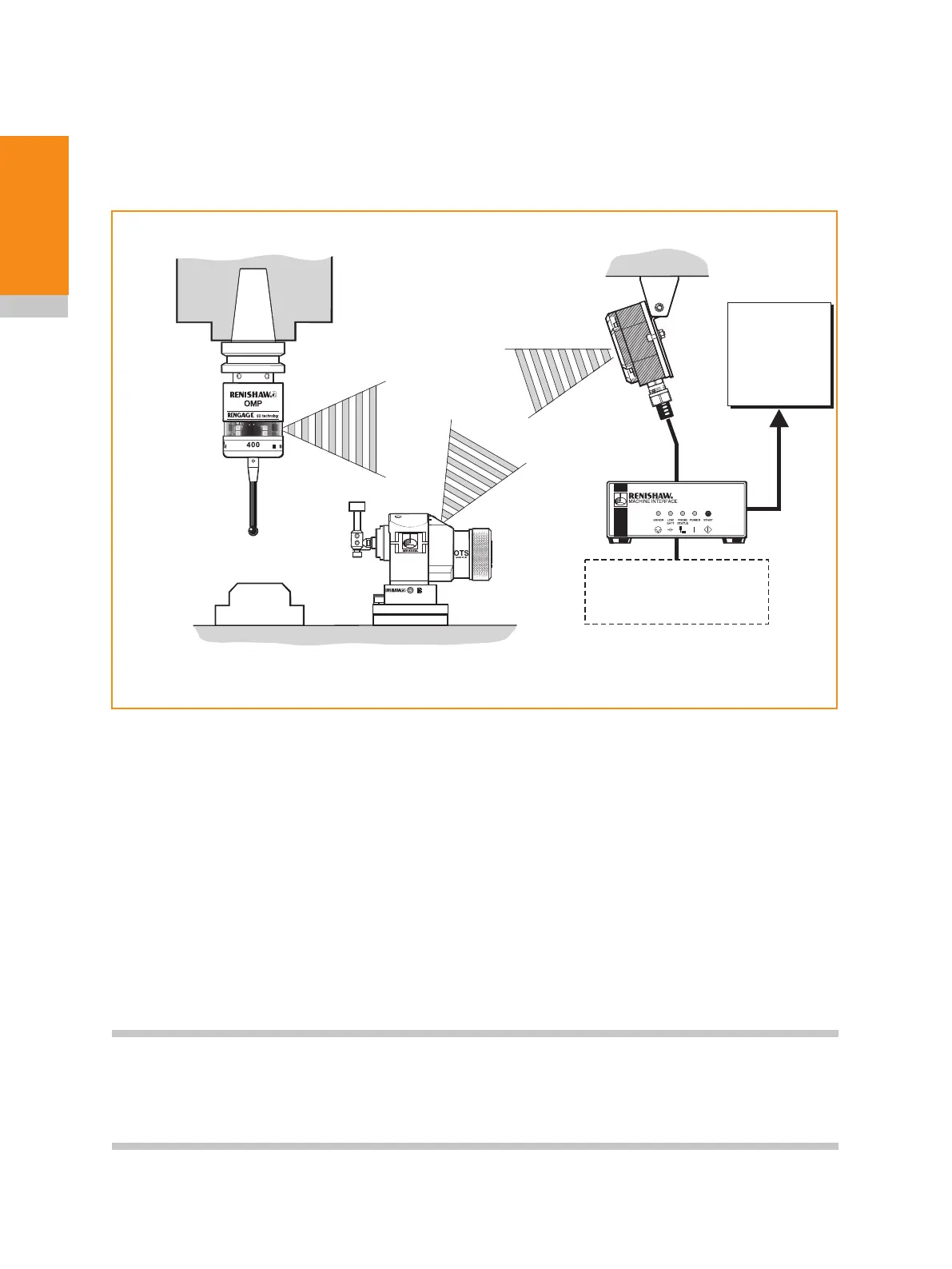

CNC machining centre spindle

CNC

machine

control

Mounting bracket

Cable

Workpiece

OMM

Stylus

Power supply

(optional)

MI 12 interface

OMP400

inspection probe

Installing the OMP400 with an OMM and MI 12

The probe and OMM diodes must be in the others field of view, and within the performance envelope

shown. The OMP400 performance envelope is based on the OMM being at 0°, and vice-versa.

Natural reflective surfaces within the machine may change the signal transmission range.

Coolant residue accumulating on the OMP400 or OMM windows will have a detrimental effect on

transmission performance. Wipe clean as often as is necessary to maintain unrestricted transmission.

Operation in temperatures of 0 °C to 5 °C or 50 °C to 60 °C (32 °F to 41 °F or 122 °F to 140 °F) will

result in some reduction in range.

On large machine tools, it is possible to provide greater reception coverage by mounting two OMMs

connected to a single MI 12 interface.

CAUTION: If two systems are operating in close proximity to each other, take care to ensure that

signals transmitted from the OMP400 on one machine are not received by the receiver on the other

machine, and vice versa. When this is the case, use of the probe’s low power mode or OMM low range

setting

Loading...

Loading...