Page 48 of 80

© Retrotec 2022

8. What to do if you have trouble with the gauge

Knowing the common causes of erroneous readings will increase your confidence in the results. It is often

assumed the gauge must be regularly calibrated in order to get accurate readings, but this thought

obscures the fact that most gauge problems do not result from incorrect calibrations. The following list

provides approximate percent probabilities based on our experience for certain types of gauge problems.

Notice that gauge calibration is one of the smallest, and even that can usually be eliminated by following

the gauge check procedures in section 7 this manual.

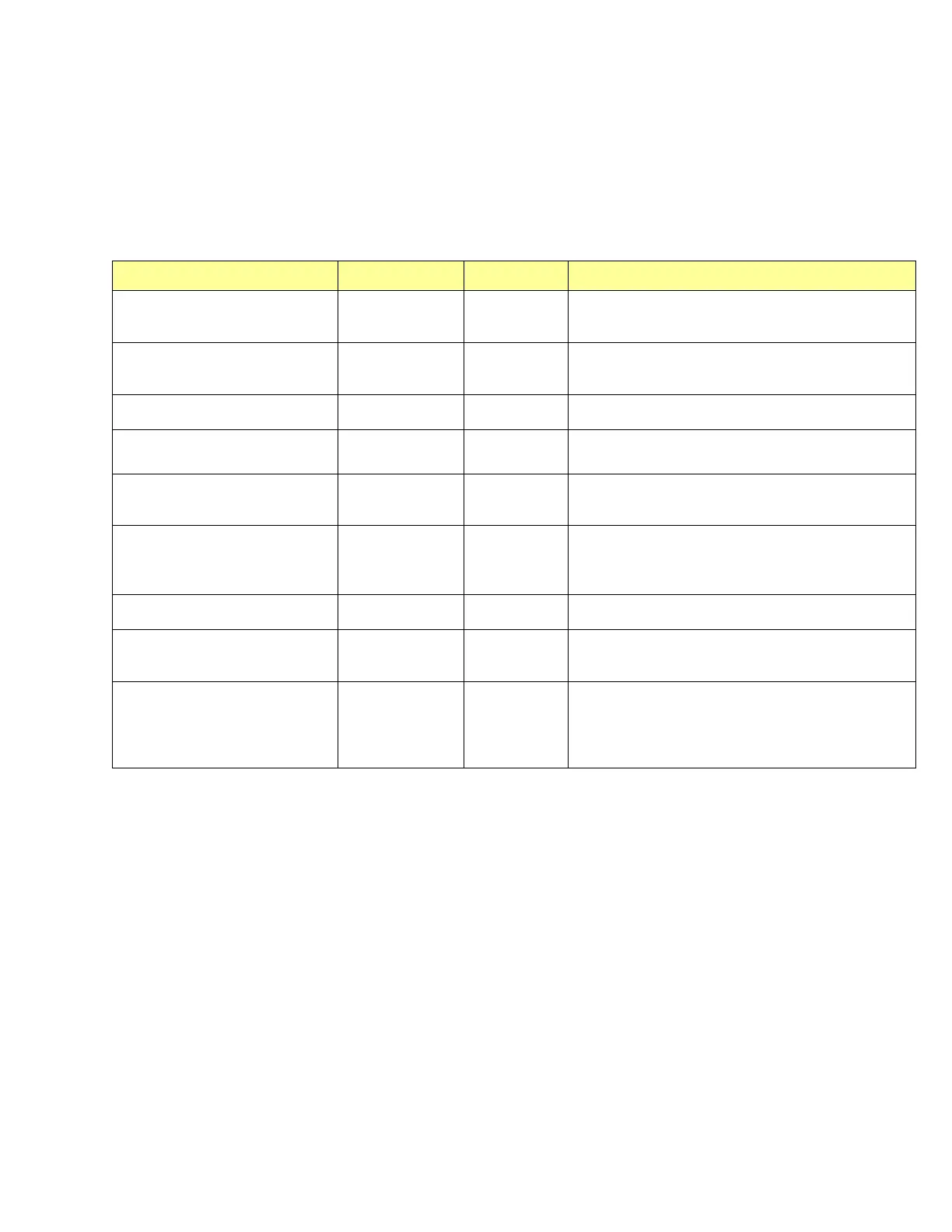

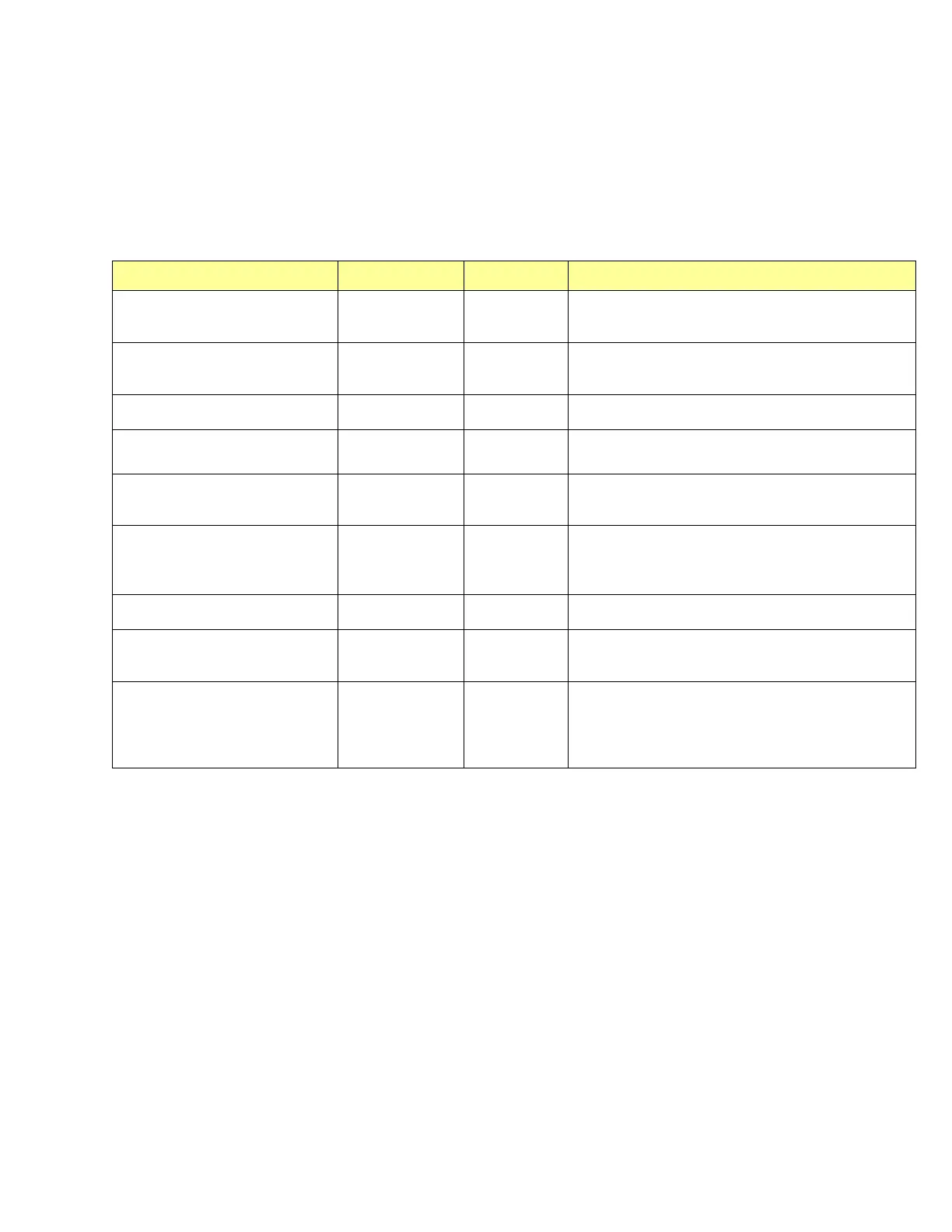

Table 2: Causes of common problems with gauges

Tubing is crimped shut

Usually noticeable because gauge does not move, but the

blockage may be partial, which could cause an erroneous

Water in tubing

Possible only in wet areas. If gauges sent in to be

repaired or calibrated, the water evaporates and the user

never discovers the cause.

Improper Device selected

Not common because the wrong Range Configuration

choices will likely be noticed on the gauge.

Improper Range Configuration

Very common unless gauges checked before and after

each measurement to ensure the right Range is in use.

Improper use of reference tube for

pressurization

Pressurization is seldom used, but if the technician is

improperly trained, they may not set the equipment up

Time averaging set too high or too

low

If the gauge is fluctuating too much it will be difficult to

read. If the time averaging is too high, the pressure may

have changed but that change is not reflected in the

Wind

These errors can be eliminated by long-term averaging or

by multiple pressure pickups.

Out of calibration

Gauges can go out of calibration in a week or may take 10

years. It is impossible to tell unless the readings seem

Out of calibration with regular

checks

Regular gauge checks can eliminate most of the

calibration problems, by identifying large errors

immediately, and before erroneous test results can be

taken. It is unlikely that errors in excess of 2% would

occur if the gauges checked before each use.

Proper training can eliminate almost all of the above errors.

8.1 Pressing power button may not turn gauge On if battery is fully

discharged

When the gauge is fully discharged, pressing the power button will not start the gauge. It is necessary to

plug the gauge in to mains power using the USB-C cable and power adapter. When the gauge is being

charged, you will see a blinking light next to the charging port. Once the light remains steady, the gauge is

fully charged. From the fully discharged state, plugging USB-C into a computer may not provide enough

current to charge, the gauge must be plugged into an outlet to re-charge.

8.2 Calculated Result will be wrong if the Range and Device

installed on fan are different than those selected on the gauge

If the results just don't make sense, check to make sure the “Range” and “Device” selected on the gauge

are the same as the Range and Device being used. Each Device and Range configuration has its own

Loading...

Loading...