Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

enquiries@hyquip.co.uk

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

Installation 29/60

RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG

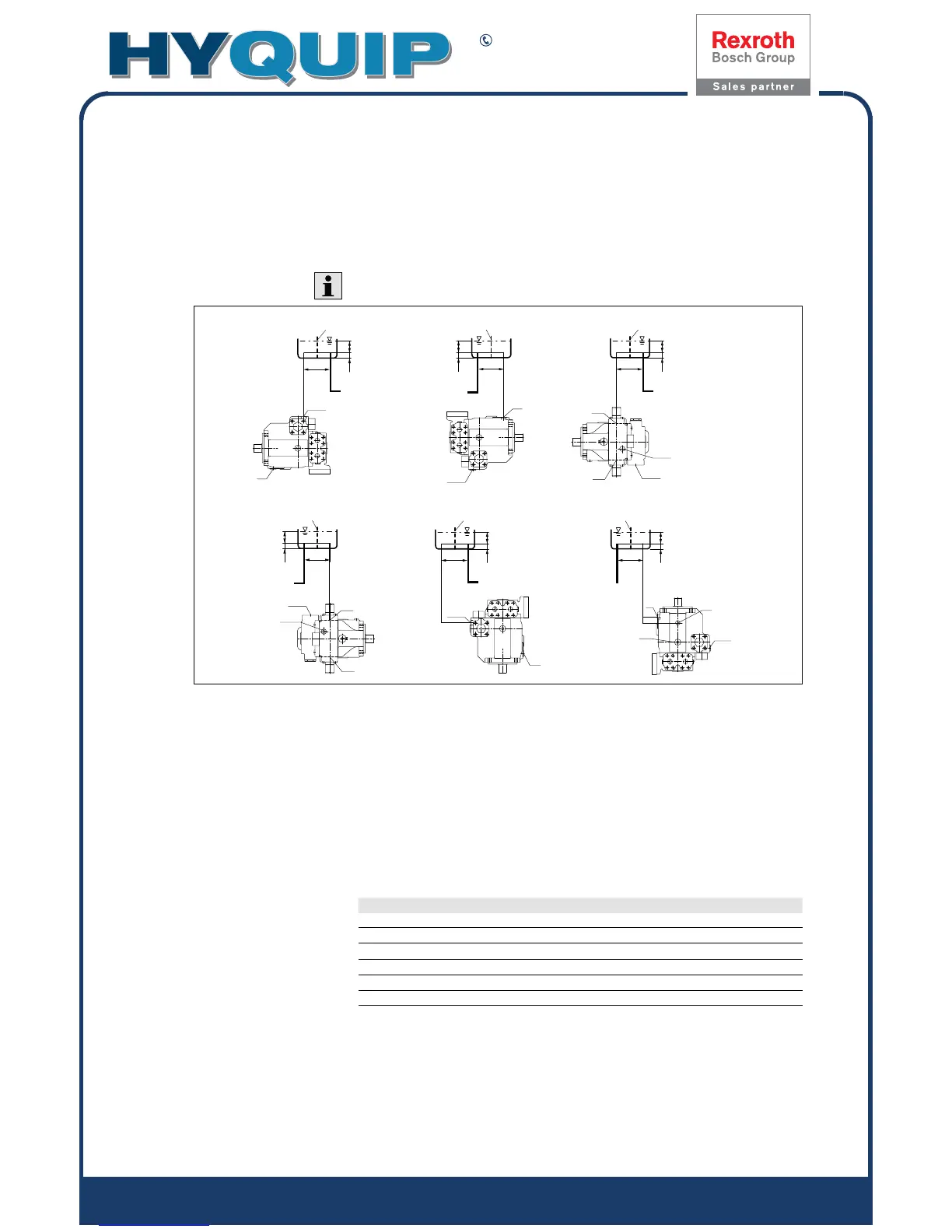

7.3.1 Below-reservoir installation (standard)

Below-reservoir installation means that the axial piston unit is installed outside of

the reservoir below the minimum fluid level.

Recommended installation positions: 1 and 2.

15 15 0

15 15 0

T

R(L)

K

3

K

3

R(L)

B(A)

B(A)

K

3

R(L)

R(L)

T

T

U

R(L)

T

R(L)

K

2

zu S

1)

a

min

SB

h

t min

h

min

zu S

1)

a

min

SB

h

t min

h

min

SB

zu S

1)

a

min

h

t min

h

min

K

2

SB SB SB

a

min

a

min

a

min

h

t min

h

min

h

t min

h

min

h

t min

h

min

zu S

1)

zu S

1)

zu S

1)

K

2

K

2

K

2

12

45 6

3

T, R(L),

K

2

, K

3

Fluid filling + air bleeding

(case drain port)

h

min

Minimum required spacing to

reservoirbottom(100mm)

A, B Pressure port a

min

When designing the reservoir, ensure

adequate distance between the

suction line and the case drain line.

This prevents the heated, return flow

from being drawn directly back into

the suction line.

S Suction port

U Bearing flushing

SB Baffle (baffle plate)

h

t min

Minimum required immersion depth

(200 mm)

Table 8: Below-reservoir installation

Installation position Filling / air bleeding housing

1 (drive shaft, horizontal) R(L)

2 (drive shaft, horizontal) T; R(L) plug

3 (drive shaft, horizontal) K

2

; R(L) plug

4 (drive shaft, horizontal) K

3

; R(L) plug

5 (drive shaft, vertically downward) R(L)

6 (drive shaft vertically upward) T; R(L) plug

1)

If an attachment pump is fitted, please note the information given in the related data sheet. For an overview of attachment pumps,

please refer to data sheetRE 92100.

Fig. 8: Below-reservoir installation: A4VSG with installation position 1–6

Loading...

Loading...