Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

enquiries@hyquip.co.uk

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

Transport and storage 23/60

RE 92100-01-B/09.2012, A4VSG Series 10, 11 and 30, Bosch Rexroth AG

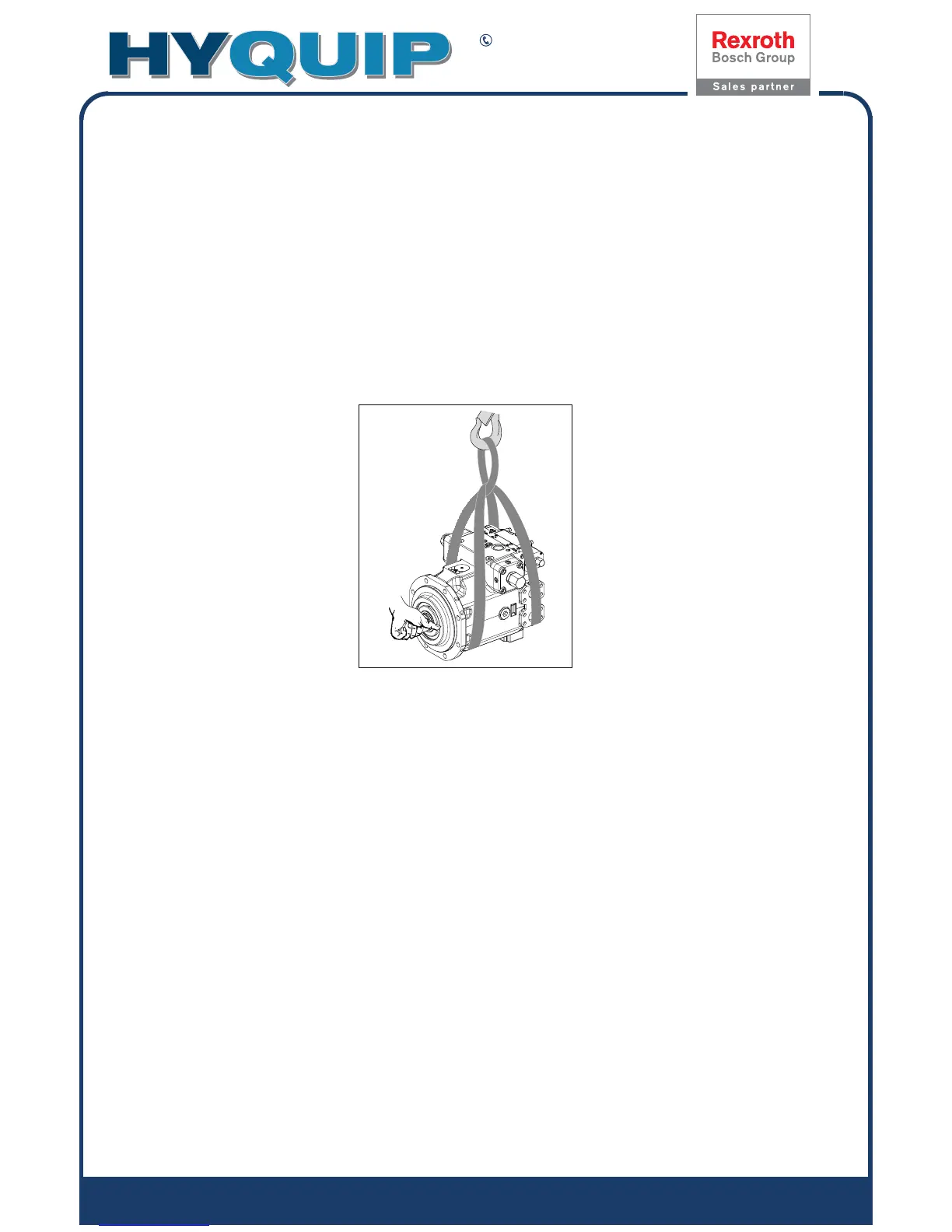

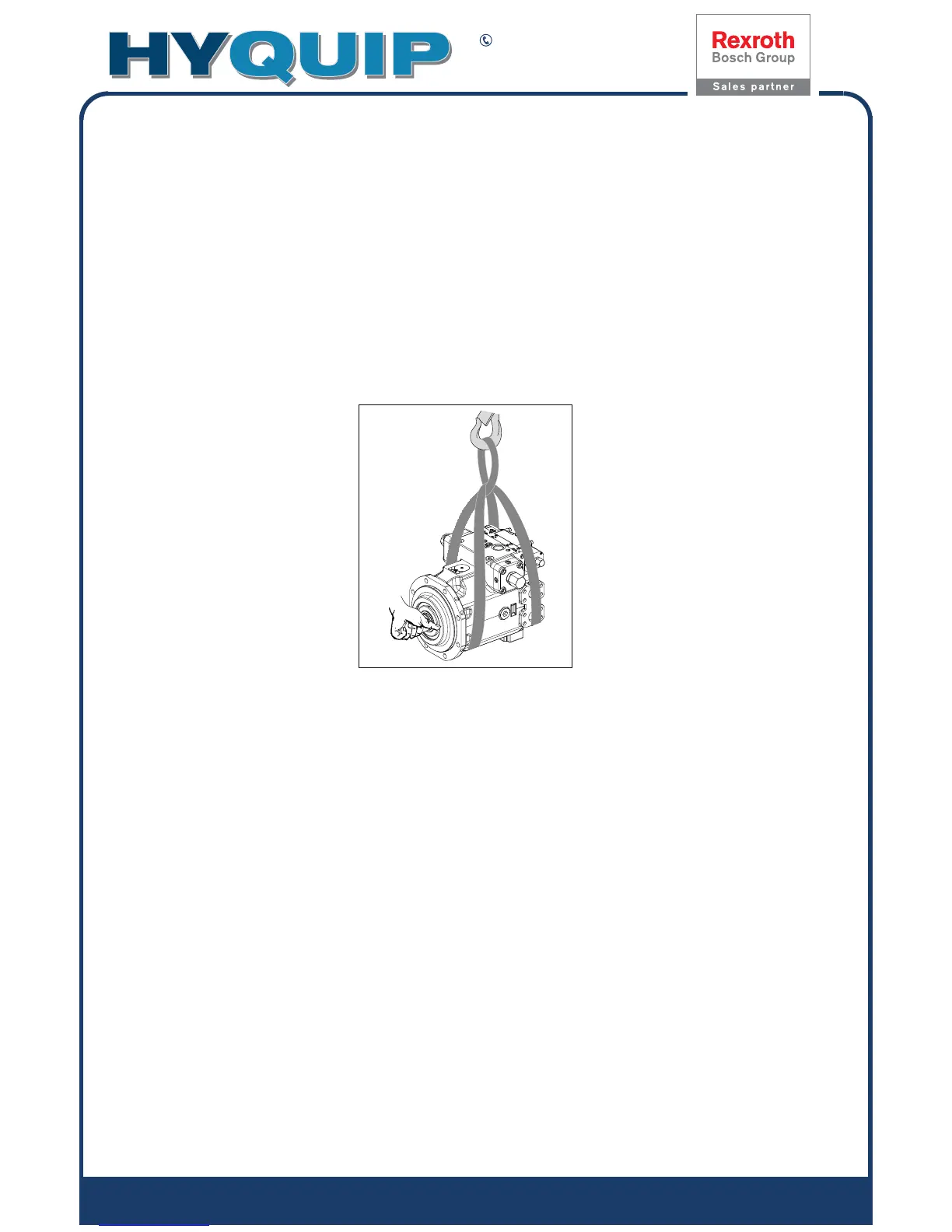

WARNING! Danger from suspended loads!

During transport with a lifting device, the axial piston unit can fall out of the lifting

strap and cause injuries.

▶ Use the widest possible lifting strap.

▶ Make sure that the axial piston unit is securely fixated with the lifting strap.

▶ Only guide the axial piston unit by hand for fine positioning and to avoid

oscillations.

▶ Never stand under or put you hands under suspended loads.

▶ Place the lifting strap around the axial piston unit in such a way that it neither

passes over the attachment parts (e.g. valves) nor that the axial piston unit is

hung from attachment parts (see Fig. 6).

Fig. 6: Transport with lifting strap

6.2 Storing the axial piston unit

t The storage areas must be free from corrosive materials and gases.

t To prevent damage to the seals, ozone-forming equipment (e.g. mercury-vapor

lamps, high voltage equipment, electric motors, sources of electrical sparks or

electrical discharges) must not be operated in storage areas.

t The storage areas must be dry.

t Ideal storage temperature: +5°C to +20°C.

t Minimum storage temperature: -50 °C (exception: units with on-board-electronics).

t Maximum storage temperature: +60°C.

t Avoid high light irradiation (e.g. bright windows or direct fluorescent lighting).

t Do not stack axial piston units and store them shock-proof.

t Do not store the axial piston unit on the drive shaft or fitting, e.g. sensors or valves.

t For further storage conditions, see Table 7.

▶ Check the axial piston unit monthly to ensure proper storage.

Transport with lifting strap

Requirements

Loading...

Loading...