Technical description of the burner

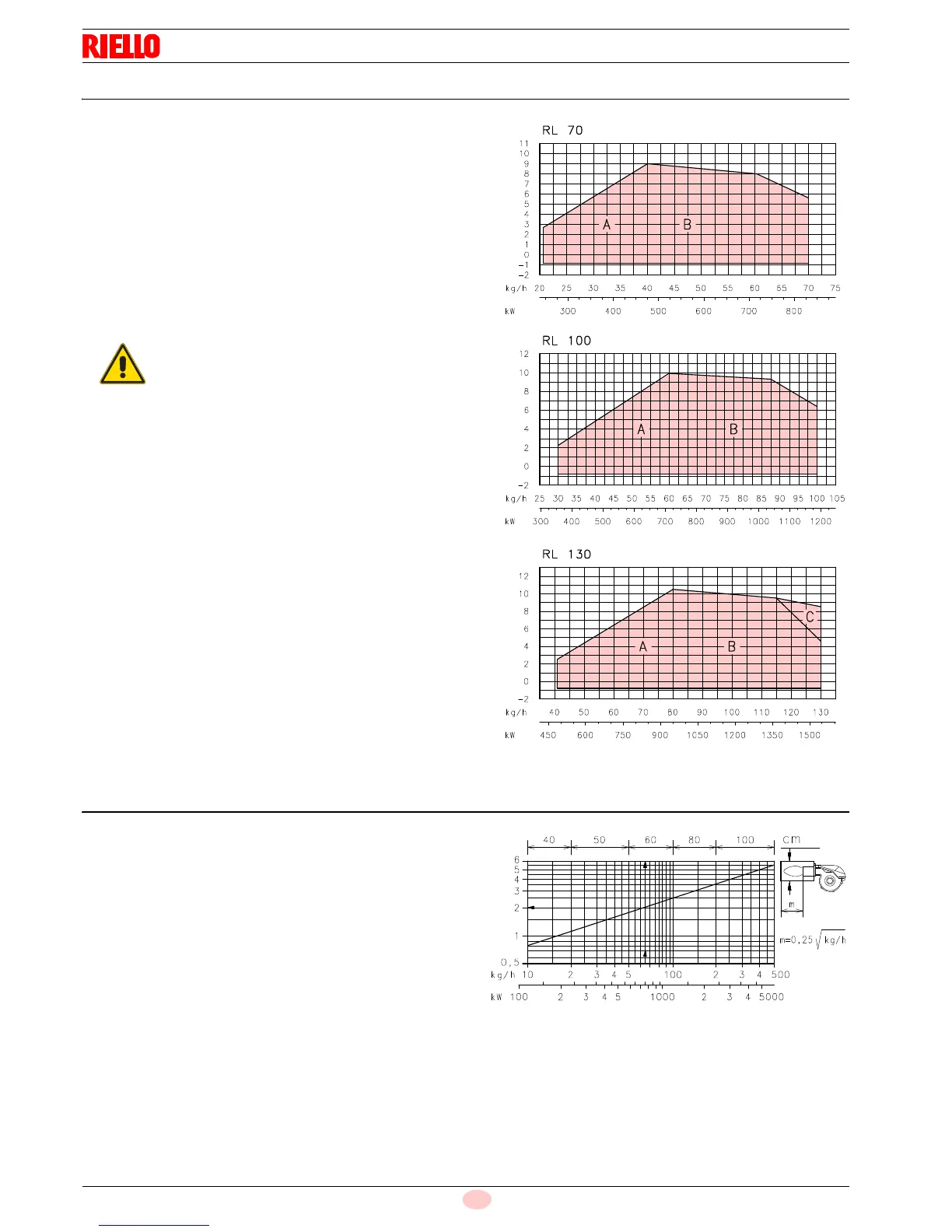

4.7 Firing rates

The RL 70 - 100 - 130 Model burners can work in two ways: one-

stage and two-stage.

1st stage DELIVERY must be selected within area A of the ad-

jacent diagrams.

2nd stage DELIVERY must be selected within area B (and C for

model RL 130). This area provides the maximum delivery of the

burner in relation to the pressure in the combustion chamber.

The work point may be found by plotting a vertical line from the

desired delivery and a horizontal line from the pressure in the

combustion chamber. The intersection of these two lines is the

work point which must lie within area B.

In order to utilize also area C (RL 130) it is necessary to perform

the calibration of the combustion head as explained on pag. 17.

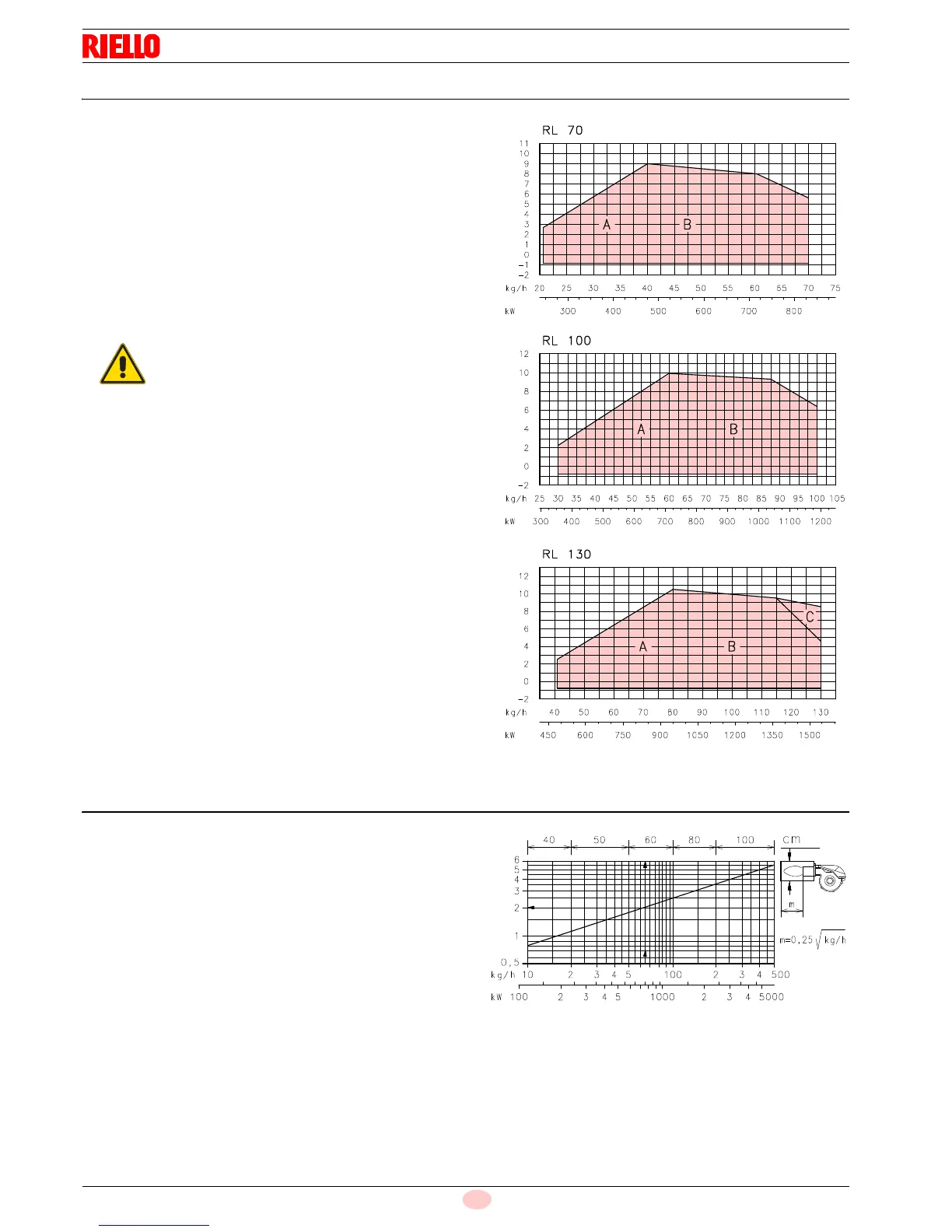

4.8 Test boiler

The firing rates were set in relation to special test boilers in ac-

cordance with the methods defined in EN 267 standards.

Fig. 4 indicates the diameter and length of the test combustion

chamber.

Example:

delivery 65 kg/hour:

diameter = 60 cm; length = 2 m.

Whenever the burner is operated in a much smaller commercial-

ly-available combustion chamber, a preliminary test should be

performed.

The firing rate value (Fig. 3) has been obtained

considering an ambient temperature of 20 °C, an

atmospheric pressure of 1013 mbar (approx. 0 m

above sea level), and with the combustion head

adjusted as shown on pag. 16.

Loading...

Loading...