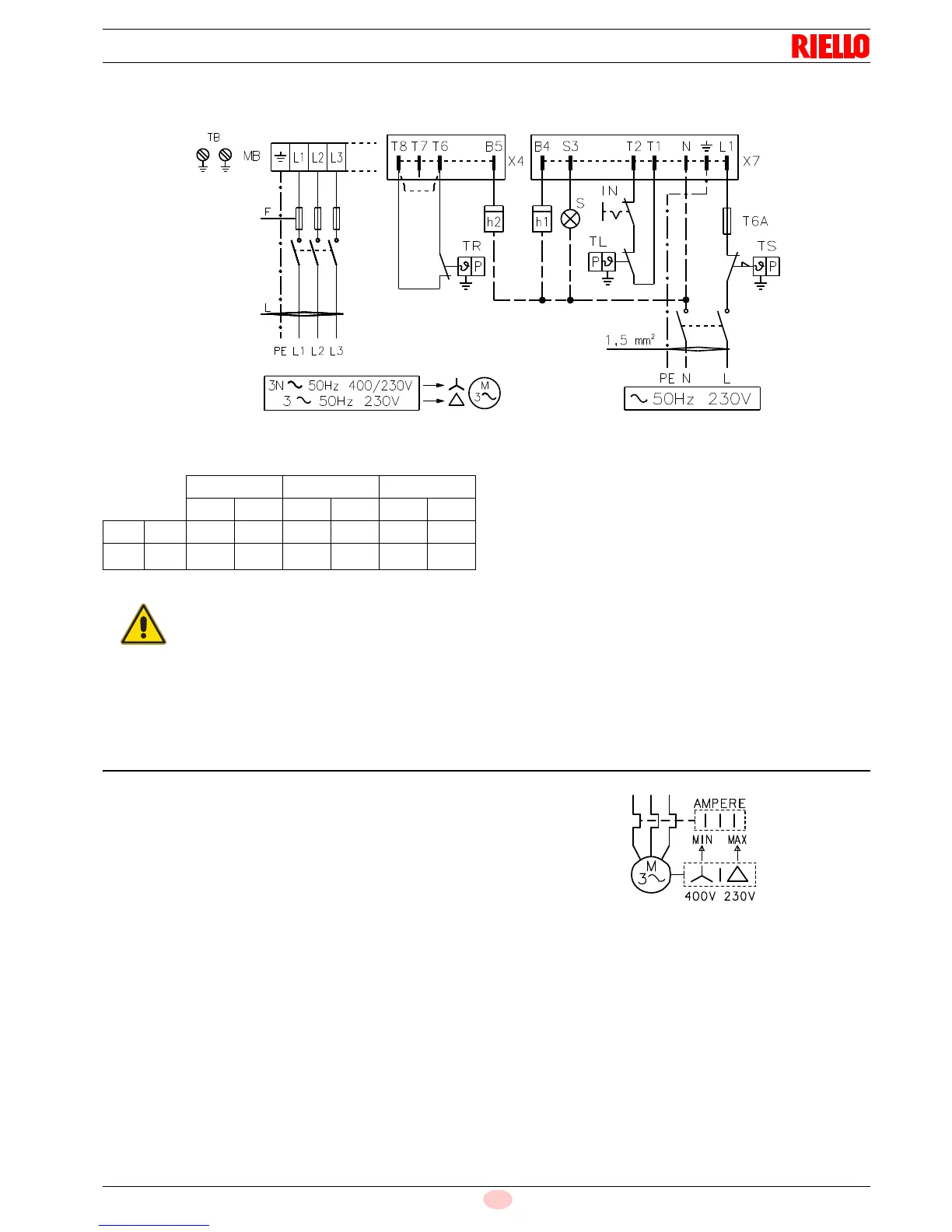

Electrical system

6.1.3 Electrical wiring to be completed by the

installer

Fuses and cables cross-section (Fig. 24), see Tab. L.

Cross-section when not indicated: 1.5 mm

2

.

Tab. L

Key to layout (Fig. 24)

h1 1st stage hourcounter

h2 2nd stage hourcounter

IN Manual burner stop switch

MB Terminal strip

S Remote lock-out signal

TB Burner ground (earth) connection

TL Limit control device system:

This shuts down the burner when the boiler temperature

or pressure exceeds the setpoint value.

TR High-low mode control device system:

This controls operating stages 1 and 2 and is necessary

only for two-stage operation.

TS Safety control device system:

This operates when TL is faulty.

X4 4 pole plug

X7 7 pole plug

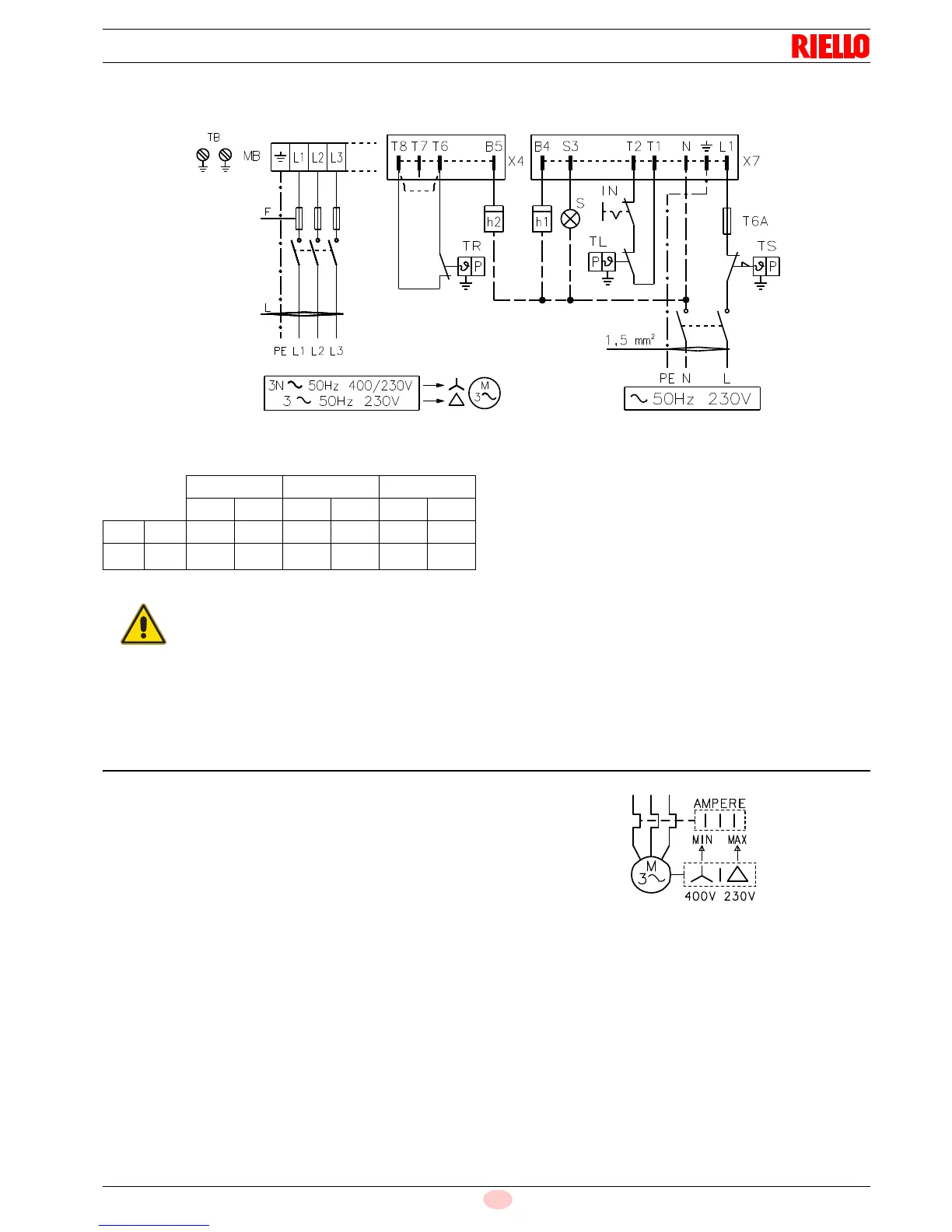

6.2 Calibration of thermal relay

This is required to avoid motor burn-out in the event of a signifi-

cant increase in power absorption caused by a missing phase.

• If the motor is star-powered, 400V, the cursor should be posi-

tioned to "MIN".

• If the motor is delta-powered, 230V, the cursor should be po-

sitioned to "MAX".

Even if the scale of the thermal cut-out does not include rated mo-

tor absorption at 400V, protection is still ensured in any case.

NOTE

The burners leaves the factory preset for 400V power sup-

ply. If 230V power supply is used, change the fan motor

connection from star to delta and change the setting of the

thermal cut-out as well.

The burners are factory set for two-stage operation and

must therefore be connected to control device TR.

Alternatively, if single stage operation is required, instead of

control device TR install a jumper lead between terminals

T8 and T6 (Fig. 24).

The burner is factory set for two-stage operation

and it must therefore be connected to the TR re-

move control device to command fuel valve V2.

Alternatively, if single stage operation is required,

instead of control device TR install a jumper lead

between terminal T8 and T6 (Fig. 24).

Loading...

Loading...