Installation

5.13 Pump

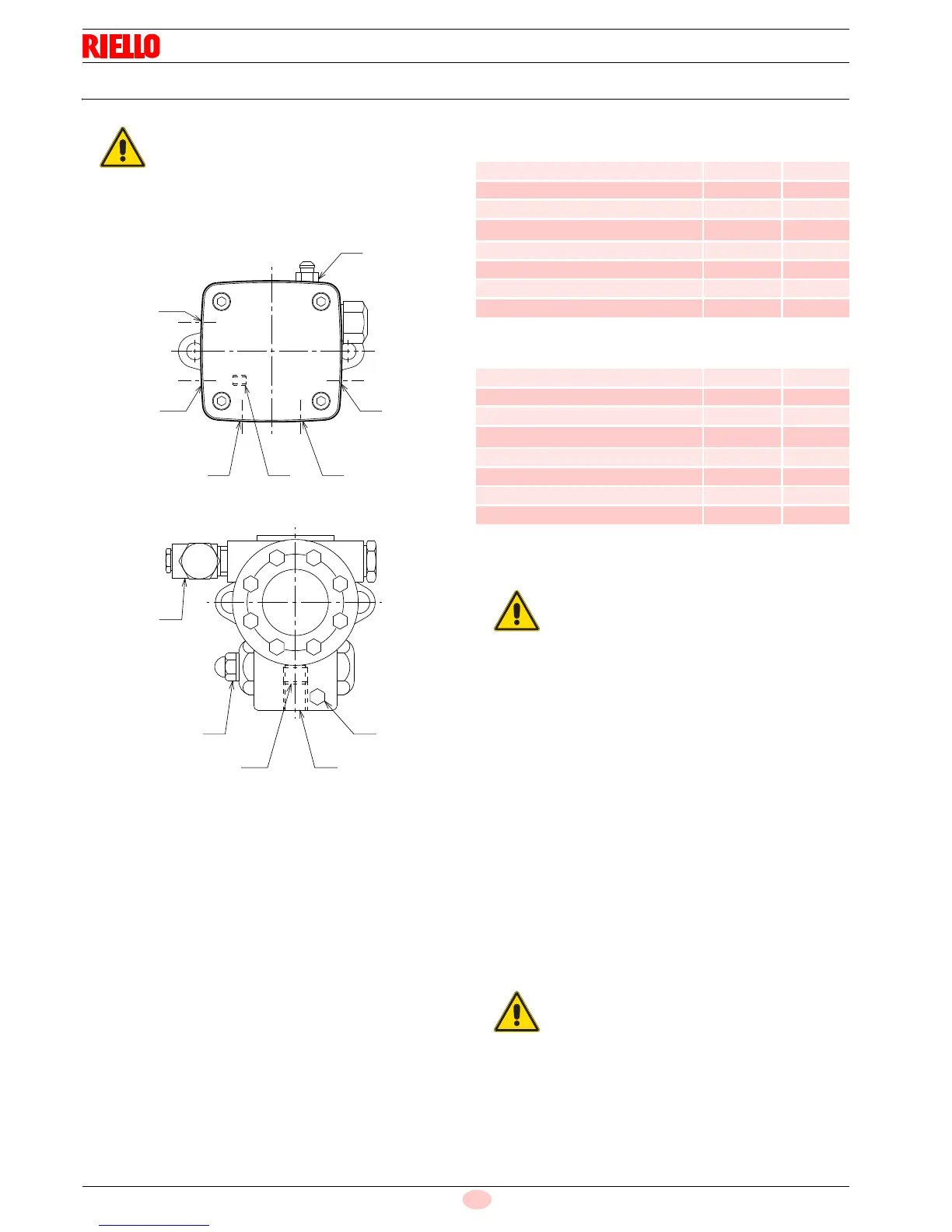

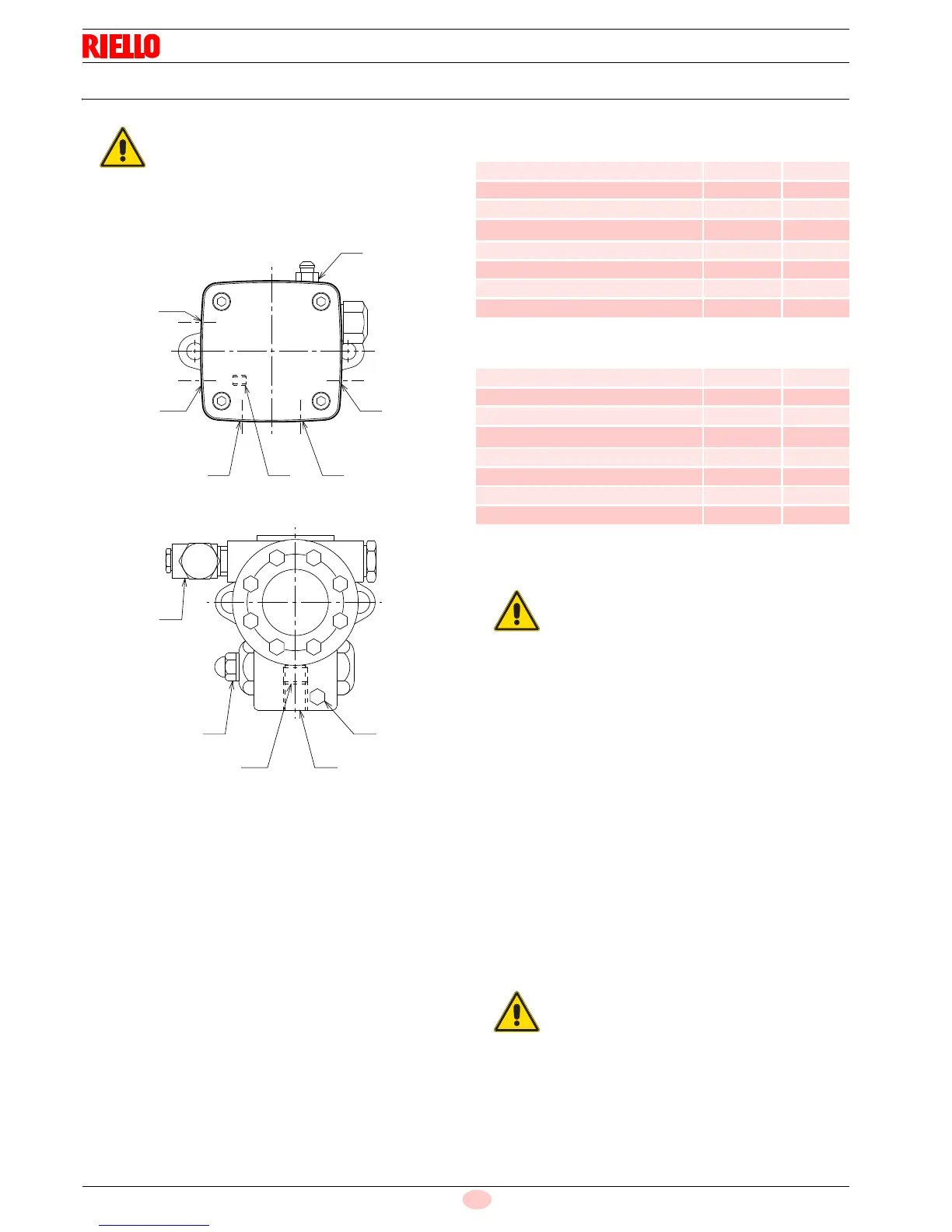

Pump RSA125 E6NC

1 - Suction G 1/4" G 1/2"

2 - Return G 1/4" G 1/2"

3 - Pressure gauge attach. G 1/8" G 1/8"

4 - Pressure adjustment screw

5 - Screw for by-pass

5.13.1 Technical data

Tab. J

Tab. K

5.13.2 Pump priming

– In order for self-priming to take place, one of the screws

3)(Fig. 20 - Fig. 21) of the pump must be loosened in order to

bleed off the air contained in the suction line.

– Start the burner by closing the control devices and with switch

1)(Fig. 26 on page 26) in the "ON" position. The pump must

rotate in the direction of the arrow marked on the cover.

– The pump can be considered to be primed when the fuel starts

coming out of the screw 3). Stop the burner: switch 1)(Fig. 26

on page 26) set to "OFF" and tighten the screw 3).

The time required for this operation depends upon the diameter

and length of the suction tubing. If the pump fails to prime at the

first starting of the burner and the burner locks out, wait approx.

15 seconds, reset the burner, and then repeat the starting oper-

ation as often as required. After 5 or 6 starting operations allow 2

or 3 minutes for the transformer to cool.

Do not illuminate the photocell or the burner will lock out; the

burner should lock out anyway about 10 seconds after it starts.

In case of use with gas oil containing up to 10%

Bio blend, it will be essential to use flexible oil

lines suitable for bio fuel use.

Please contact Riello for further information.

RL 70-100

D8768

PUMP DANFOSS RSA125

RL 130

PUMP SUNTEC E6NC

D8769

Pump DANFOSS RSA125

Min. delivery rate at 12 bar pressure kg/h 190

Delivery pressure range bar 5.5 - 21

Max. suction depression bar 0.4

Viscosity range

mm

2

/s (cSt)

1.3 - 75

Max. gas oil temperature °C 120

Max. suction and return pressure bar 4

Pressure calibration in the factory bar 12

Filter mesh width mm 0.150

Pump SUNTEC E6NC

Min. delivery rate at 12 bar pressure kg/h 208

Delivery pressure range bar 10 - 21

Max. suction depression bar 0.45

Viscosity range

mm

2

/s (cSt)

1.8 - 200

Max. gas oil temperature °C 90

Max. suction and return pressure bar 1.5

Pressure calibration in the factory bar 12

Filter mesh width mm 0.170

Before starting the burner, make sure that the

tank return line is not clogged.

Obstructions in the line could cause the seal-

ing organ located on the pump shaft to break.

(The pump leaves the factory with the by-pass

closed).

the a.m. operation is possible because the pump

is already full of fuel when it leaves the factory. If

the pump has been drained, fill it with fuel through

the opening on the vacuum meter prior to starting;

otherwise, the pump will seize. Whenever the

length of the suction piping exceeds 20-30 me-

ters, the supply line must be filled using a sepa-

rate pump.

Loading...

Loading...