Installation

Example with the RL 70 Model (gas oil)

Boiler output = 635 kW - efficiency 90 %

Output required by the burner =

therefore, two equal, 60°, 12 bar nozzles are required:

1st = 7.0 GPH - 2° = 7.0 GPH,

or the following two different nozzles:

1st = 6.0 GPH - 2° = 8.0 GPH,

or:

1st = 8.0 GPH - 2° = 6.0 GPH.

KEROSENE

Tab. G

(1)

We get the indicated delivery when both nozzles are work-

ing and kerosene has the following characteristics: density

0.81 kg/dm3 - viscosity 1.6 cSt/20 °C - temperature 25 °C.

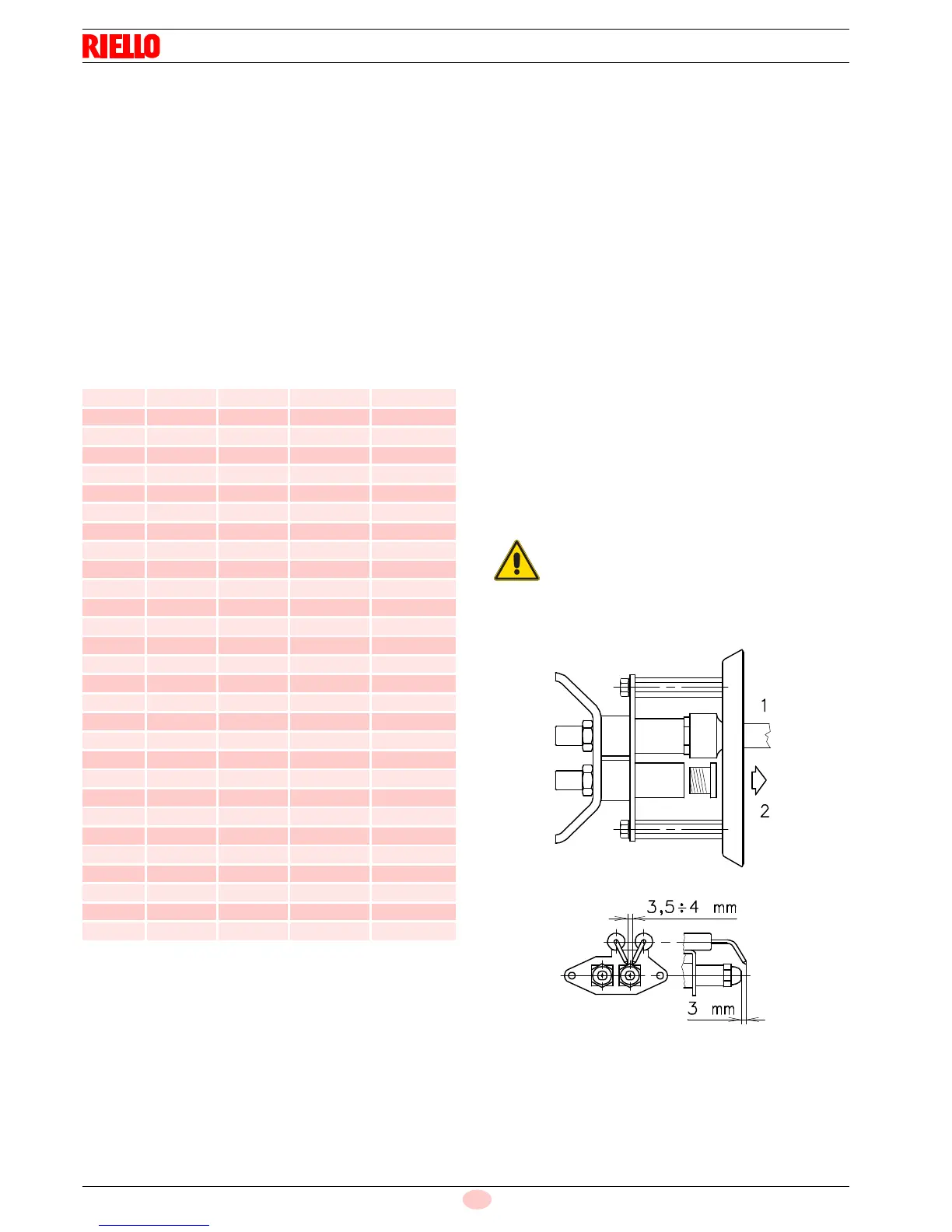

5.10.2 Nozzle assembly

At this stage of installation the burner is still disassembled from

the blast tube; it is therefore possible to fit two nozzles with the

box spanner 1)(Fig. 13) (16 mm), after having removed the plas-

tic plugs 2)(Fig. 13), fitting the spanner through the central hole in

the flame stability disk. Do not use any sealing products such as

gaskets, sealing compound, or tape. Be careful to avoid damag-

ing the nozzle sealing seat. The nozzles must be screwed into

place tightly but not to the maximum torque value provided by the

wrench.

The nozzle for the 1st stage of operation is the one lying beneath

the firing electrodes (Fig. 14).

Make sure that the electrodes are positioned as shown in Figure

(Fig. 14).

Finally remount the burner 3)(Fig. 15 on page 19) to the slide

bars 2) and slide it up to the flange 5), keeping it slightly raised to

prevent the flame stability disk from pressing against the blast

tube.

Tighten the screws 1) on the slide bars 2) and screws 4) fixing the

burner to the flange.

If it proves necessary to change a nozzle with the burner already

fitted to the boiler, proceed as outlined below:

– Retract the burner on its slide bars as shown in (Fig. 9 on

page 16).

– Remove the nuts 1) (Fig. 16 on page 19) and the disk 2).

– Use spanner 3) (Fig. 16 on page 19) to change the nozzles.

635 : 0,9 = 705 kW;

705 : 2 = 352 kW per nozzle;

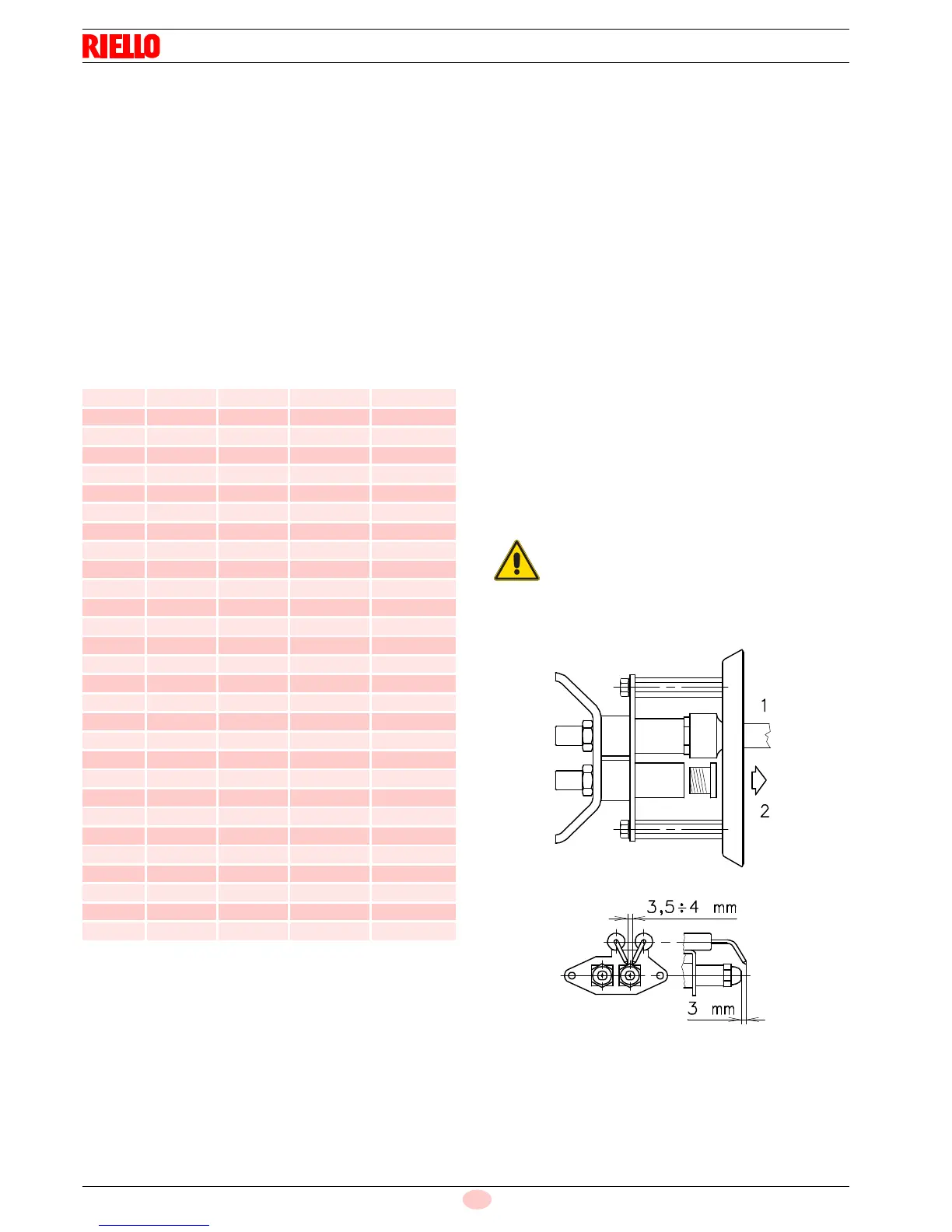

GPH

kg/h (1)

kW

10 bar

8 bar 9 bar 10 bar

6.5 19.01 20.26 21.44 256.8

7.0 20.47 21.82 23.09 276.5

7.5 21.94 23.38 24.74 296.3

8.0 23.40 24.93 26.39 316.0

8.5 24.86 26.49 28.04 335.8

9.0 26.32 28.05 29.69 355.6

9.5 27.78 29.61 31.34 375.3

10.0 29.25 31.17 32.99 395.1

10.5 30.71 32.73 34.64 414.9

11.0 32.17 34.28 36.29 434.6

11.5 33.63 35.84 37.94 454.4

12.0 35.10 37.40 39.59 474.2

13.0 38.02 40.52 42.89 513.7

13.5 39.48 42.08 44.54 533.4

14.0 40.95 43.63 46.19 533.2

15.0 43.87 46.75 49.49 592.7

15.5 45.33 48.31 51.14 612.5

16.0 46.79 49.87 52.79 632.2

17.0 49.72 52.98 56.09 671.8

17.5 51.18 54.54 57.74 691.5

18.0 52.64 56.10 59.39 711.3

19.0 55.57 59.22 62.69 750.8

19.5 57.03 60.78 64.33 770.5

20.0 58.49 62.33 65.98 790.2

21.5 62.88 67.01 70.93 849.5

22.0 64.34 68.57 72.58 869.3

24.0 70.19 74.80 79.18 948.3

26.0 76.04 81.04 85.78 1027.4

28.0 81.89 87.27 92.38 1106.4

Loading...

Loading...