Installation

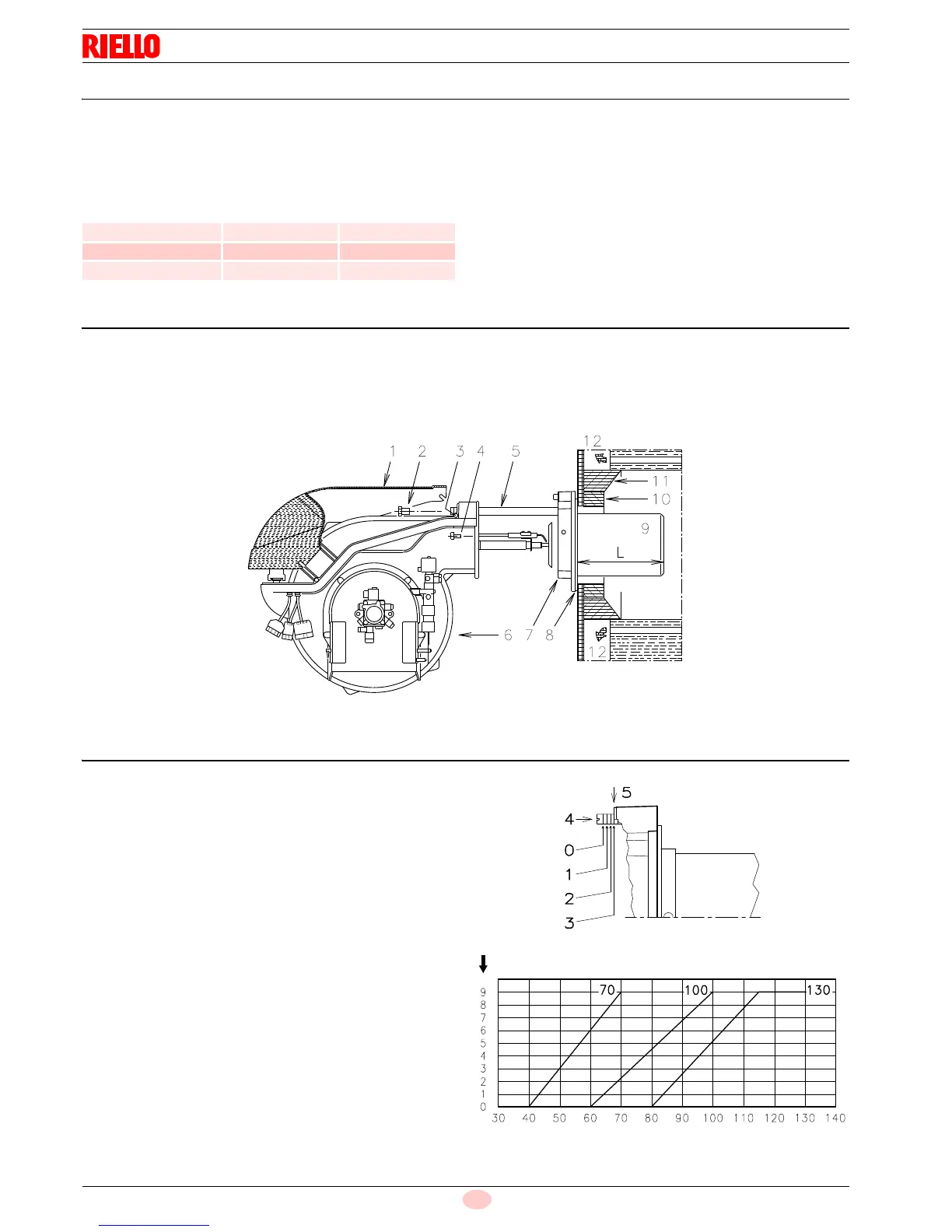

5.7 Blast tube length

The length of the blast tube must be selected according to the in-

dications provided by the manufacturer of the boiler, and in any

case it must be greater than the thickness of the boiler door com-

plete with its fettling.

The range of lengths available, L (mm), is as follows:

For boilers with front flue passes 13)(Fig. 9) or flame inversion

chambers, protective fettling in refractory material 11) must be in-

serted between the boiler fettling 12) and the blast tube 10).

This protective fettling must not compromise the extraction of the

blast tube.

For boilers having a water-cooled front the refractory fettling 11)-

12)(Fig. 9) is not required unless it is expressly requested by the

boiler manufacturer.

5.8 Securing the burner to the boiler

Disassemble the blast tube 9) from the burner 6) by proceeding

as follows:

– Loosen the four screws 3) and remove the cover 1).

– Remove the screws 2) from the two slide bars 5).

– Remove the two screws 4) fixing the burner 6) to the flange 5).

– Withdraw the blast tube 9) complete with flange 7) and slide

bars 5).

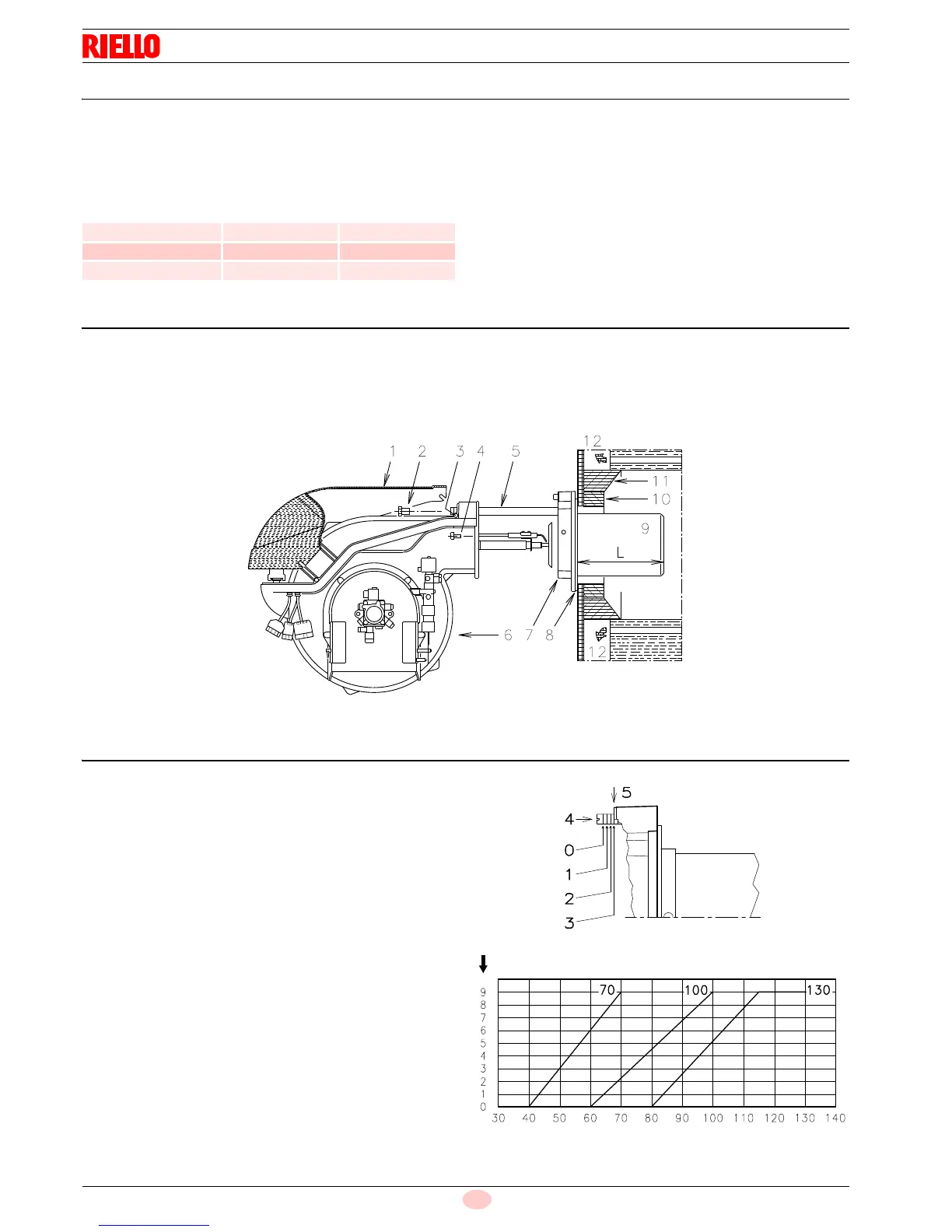

5.9 Combustion head setting

The setting of the combustion head depends exclusively on the

delivery of the burner in the 2nd stage - in other words, the com-

bined delivery of the two nozzles selected on pag. 17.

Turn screw 4)(Fig. 10) until the notch shown in diagram (Fig. 11)

is level with the front surface of flange 5)(Fig. 10).

Example:

The RL 70 Model with two 6.0 GPH nozzles and 12 bar pump

pressure.

Find the delivery in Tab. F on page 17:

25.5 + 25.5 = 51 kg/h.

Diagram (Fig. 11) indicates that for a delivery of 51 kg/h the RL

70 Model requires the combustion head to be set to approx. three

notches, as shown in (Fig. 10).

Blast tube 10)(Fig. 9) Short Long

RL 70 250 385

RL 100 250 385

RL 130 250 385

Loading...

Loading...