Start-up, calibration and operation of the burner

7.3.2 Steady state operation

System equipped with one control device TR

Once the starting cycle has come to an end, the command of the

2nd stage solenoid valve passes on to the control device TR that

controls boiler temperature or pressure.

• When the temperature or the pressure increases until the con-

trol device TR opens, solenoid valve 11) closes, and the burn-

er passes from the 2nd to the 1st stage of operation.

• When the temperature or pressure decreases until the control

device TR closes, solenoid valve 11) opens, and the burner

passes from the 1st to the 2nd stage of operation, and so on.

• The burner stops when the demand for heat is less than the

amount of heat delivered by the burner in the 1st stage. In this

case, the control device TL opens, and solenoid valves 8)-16)

close, the flame immediately goes out. The fan's air gate valve

closes completely.

Systems not equipped with control device TR (jumper wire

installed)

The burner is fired as described in the case above. If the temper-

ature or pressure increase until control device TL opens, the

burner shuts down (Section A-A in the diagram).

When the solenoid valve 11) de-energizes, the piston 12) closes

the passage to the 2nd stage nozzle and the fuel contained in the

cylinder 15), piston B, is discharged into the return piping 7).

7.3.3 Firing failure

If the burner does not fire, it goes into lock-out within 5 s of the

opening of the 1st nozzle valve and 30 s after the closing of con-

trol device TL.

The control box red pilot light will light up.

7.3.4 Undesired shutdown during operation

If the flame goes out during operation, the burner shuts down au-

tomatically within 1 second and automatically attempts to start

again by repeating the starting cycle.

7.3.5 Final checks

• Obscure the photocell and switch on the control devices: the

burner should start and then lock-out about 5 s after opening

of the 1st stage operation valve.

• Illuminate the photocell and switch on the control devices: the

burner should start and then go into lock-out after about 10 s.

• Obscure the photocell while the burner is in 2nd stage opera-

tion, the following must occur in sequence: flame extinguished

within 1 s, pre-purging for about 20 s, sparking for about 5 s,

burner goes into lock out.

• Switch off control device TL followed by control device TS

while the burner is operating: the burner should stop.

7.4 Burner start-up cycle diagnostics

During start-up, indication is according to the Tab. O:

Tab. O

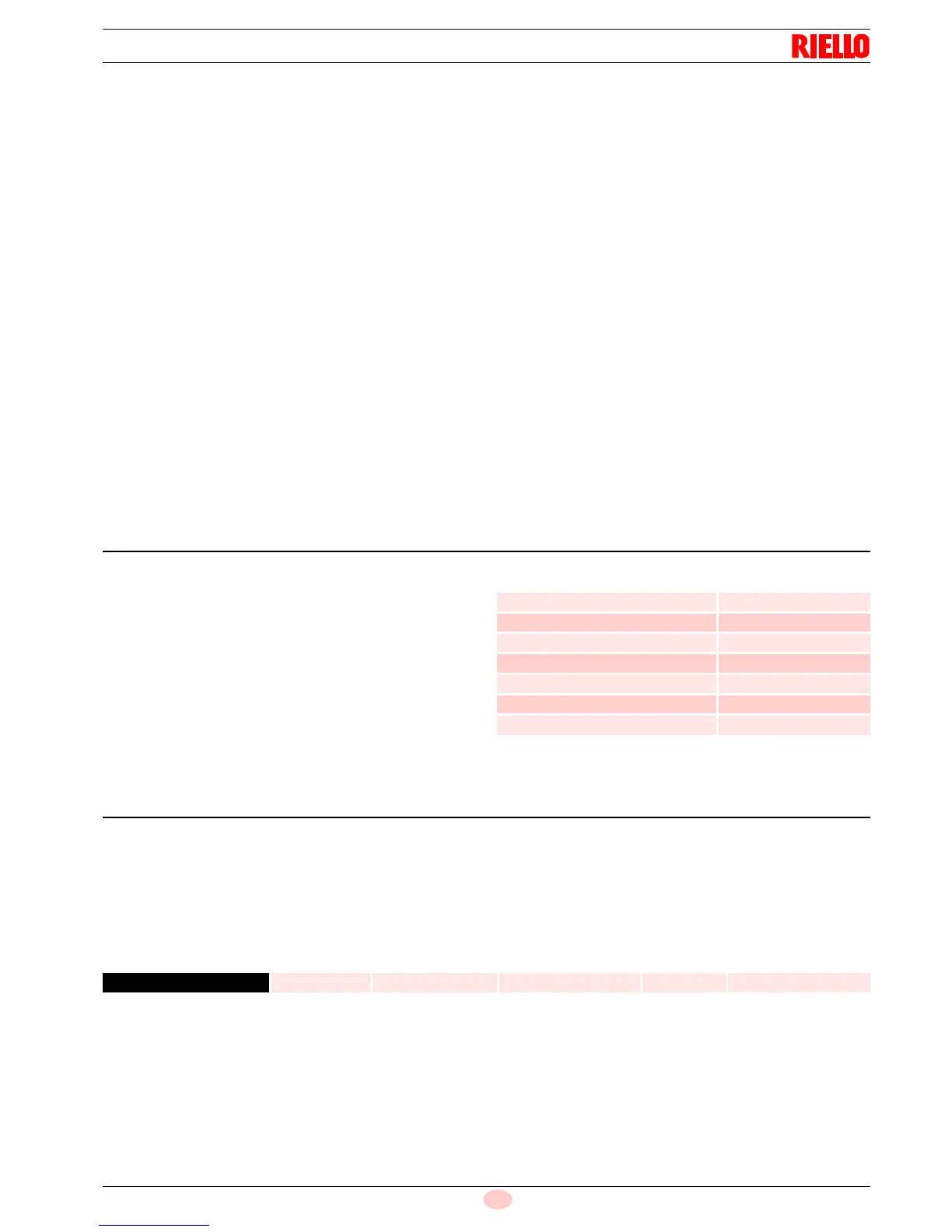

7.5 Resetting the control box and using diagnostics

The control box features a diagnostics function through which

any causes of malfunctioning are easily identified (indicator: RED

LED).

To use this function, you must wait at least 10 seconds once it

has entered the safety condition (lockout), and then press the re-

set button.

The control box generates a sequence of pulses (1 second

apart), which is repeated at constant 3-second intervals.

Once you have seen how many times the light pulses and identi-

fied the possible cause, the system must be reset by holding the

button down for between 1 and 3 seconds.

The methods that can be used to reset the control box and use

diagnostics are given below.

Sequences Colour code

Pre-purging

Ignition phase

Operation, flame ok

Operating with weak flame signal

Electrical supply lower than ~ 170V

Lock-out

Extraneous light

Key: Off Yellow Green Red

RED LED on

wait at least 10s

Lock-out

Press reset

for > 3s

Pulses

Interval

3s

Pulses

Loading...

Loading...