Maintenance

8.1 Notes on safety for the maintenance

The periodic maintenance is essential for the good operation,

safety, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and

to keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking oper-

ations:

8.2 Maintenance programme

8.2.1 Maintenance frequency

8.2.2 Checking and cleaning

Combustion

The optimum calibration of the burner requires an analysis of the

flue gases. Significant differences with respect to the previous

measurements indicate the points where more care should be

exercised during maintenance.

Pump

The delivery pressure must be stable.

The depression must be less than 0.4 bar.

Unusual noise must not be evident during pump operation.

If the pressure is found to be unstable or if the pump runs noisily,

the flexible hose must be detached from the line filter and the fuel

must be sucked from a tank located near the burner. This meas-

ure permits the cause of the anomaly to be traced to either the

suction piping or the pump.

If the pump is found to be responsible, check to make sure that

the filter is not dirty. The vacuum meter is installed upstream from

the filter and consequently will not indicate whether the filter is

clogged or not.

Contrarily, if the problem lies in the suction line, check to make

sure that the filter is clean and that air is not entering the piping.

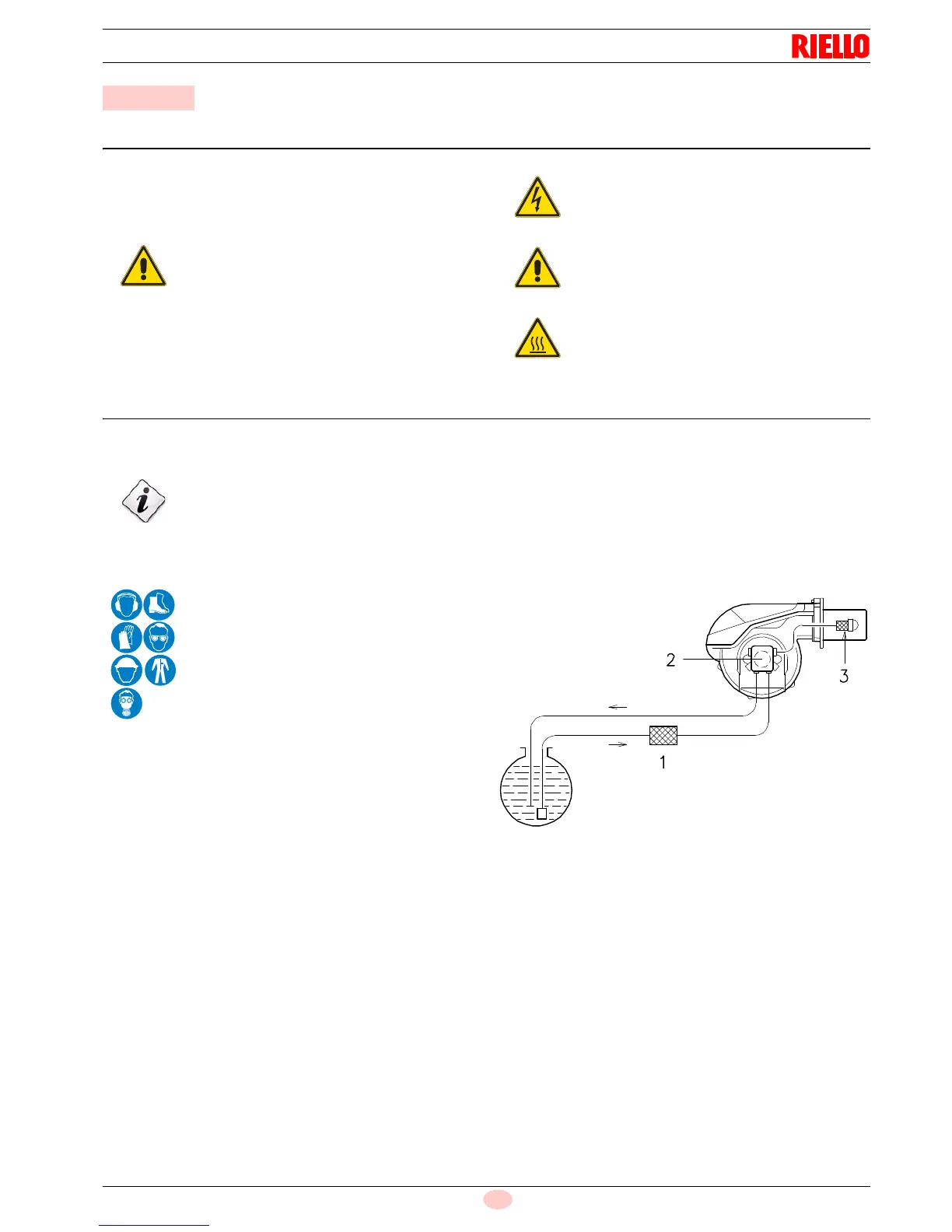

Filters (Fig. 32)

Check the following filter boxes:

• on line 1) • in the pump 2) • at the nozzle 3), and clean or replace

as required.

If rust or other impurities are observed inside the pump, use a

separate pump to lift any water and other impurities that may

have deposited on the bottom of the tank. Then clean the insides

of the pump and the cover sealing surface.

Fan

Check to make sure that no dust has accumulated inside the fan

or on its blades, as this condition will cause a reduction in the air

flow rate and provoke polluting combustion.

Combustion Head

Check to make sure that all the parts of the combustion head are

in good condition, positioned correctly, free of all impurities, and

that no deformation has been caused by operation at high tem-

peratures.

Nozzles

Do not clean the nozzle openings; do not even open them. The

nozzle filters however may be cleaned or replaced as required.

Replace the nozzles every 2-3 years or whenever necessary.

Combustion must be checked after the nozzles have been

changed.

8 Maintenance

Loading...

Loading...