Installation

5.9.1 Combustion head calibration

At this point check, for model RL 130, whether the maximum de-

livery of the burner in 2nd stage operation is contained in area B

or in area C of the firing rate. See pag. 12.

If it is in area B then no operation is required.

If, on the other hand, it is in area C:

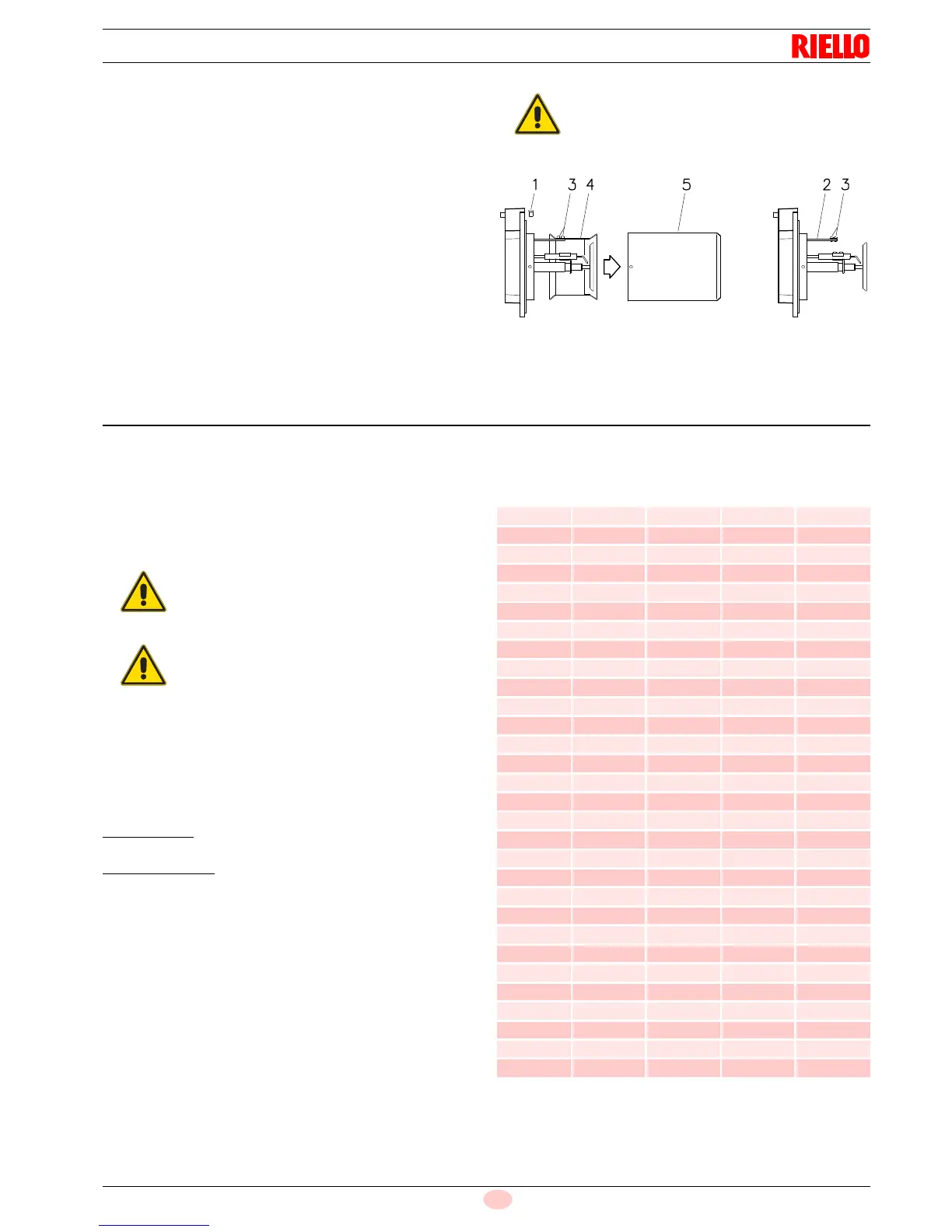

– Unscrew the screws 1)(Fig. 12) and disassemble the blast

tube 5).

– Unscrew the screws 3) and remove the shutter 4).

– Tighten the screws 3) on the rod 2).

– Now refit the blast tube 5) and the screws 1).

Once this operation has been carried out (if it was required), se-

cure flange 7)(Fig. 9) to the boiler plate interposing the supplied

gasket 8).

Use the 4 screws provided after having protected the thread with

antiscruffing products (high-temperature grease, compounds,

graphite).

5.10 Nozzle installation

5.10.1 Choice of nozzles for 1

st

and 2

nd

stage

The burner complies with the emission requirements of the

EN 267 standard.

In order to guarantee that emissions do not vary, recommended

and/or alternative nozzles specified by Riello in the Instruction

and warning booklet should be used.

Both nozzles must be chosen from among those listed in Tab. F.

The first nozzle

determines the delivery of the burner in the 1st

stage.

The second nozzle

works together with the 1st nozzle to deter-

mine the delivery of the burner in the 2nd stage.

The deliveries of the 1st and 2nd stages must be contained within

the value range indicated on pag. 10.

Use nozzles with a 60° spray angle at the recommended pres-

sure.

The two nozzles usually have equal deliveries, but the 1st stage

nozzle may have the following specifications if required:

• a delivery less than 50% of the total delivery whenever the

back-pressure peak must be reduced at the moment of fir-

ing: the burner allows good combustion values also with a

ratio 40 - 100 % between the 1st and 2nd stage;

• a delivery higher than 50% of the total delivery whenever

the combustion during the 1st stage must be improved.

GAS OIL

Tab. F

(1)

We get the indicated delivery when both nozzles are work-

ing and gas oil has the following characteristics: density

0.84 kg/dm3 - viscosity 4.2 cSt/20 °C - temperature 10 °C

The use of nozzles other than those specified by

Riello S.p.A. and inadequate regular maintenance

may result into emission limits non-conforming to

the values set forth by the regulations in force, and

in extremely serious cases, into potential hazards

to people and objects.

The manufacturing company shall not be liable for

any such damage arising from nonobservance of

the requirements contained in this manual.

GPH

kg/h (1)

kW

12 bar

10 bar 12 bar 14 bar

5.00 19.2 21.2 23.1 251.4

5.50 21.1 23.3 25.4 276.3

6.00 23.1 25.5 27.7 302.4

6.50 25.0 27.6 30.0 327.3

7.00 26.9 29.7 32.3 352.3

7.50 28.8 31.8 34.6 377.2

8.00 30.8 33.9 36.9 402.1

8.30 31.9 35.2 38.3 417.5

8.50 32.7 36.1 39.2 428.2

9.00 34.6 38.2 41.5 453.1

9.50 36.5 40.3 43.8 478.0

10.0 38.4 42.4 46.1 502.9

10.5 40.4 44.6 48.4 529.0

11.0 42.3 46.7 50.7 553.9

12.0 46.1 50.9 55.3 603.7

12.3 47.3 52.2 56.7 619.1

13.0 50.0 55.1 59.9 653.5

13.8 53.1 58.5 63.3 693.8

14.0 53.8 59.4 64.5 704.5

15.0 57.7 63.6 69.2 754.3

15.3 58.8 64.9 70.5 769.7

16.0 61.5 67.9 73.8 805.3

17.0 65.4 72.1 78.4 855.1

17.5 67.3 74.2 80.7 880.0

18.0 69.2 76.4 83.0 906.1

19.0 73.0 80.6 87.6 956.0

19.5 75.0 82.7 89.9 980.9

20.0 76.9 84.8 92.2 1005.8

21.5 82.7 91.2 99.1 1081.7

22.0 84.6 93.3 101.4 1106.6

Loading...

Loading...