Start-up, calibration and operation of the burner

Example RL 70 - 1st stage nozzle 6.0 GPH:

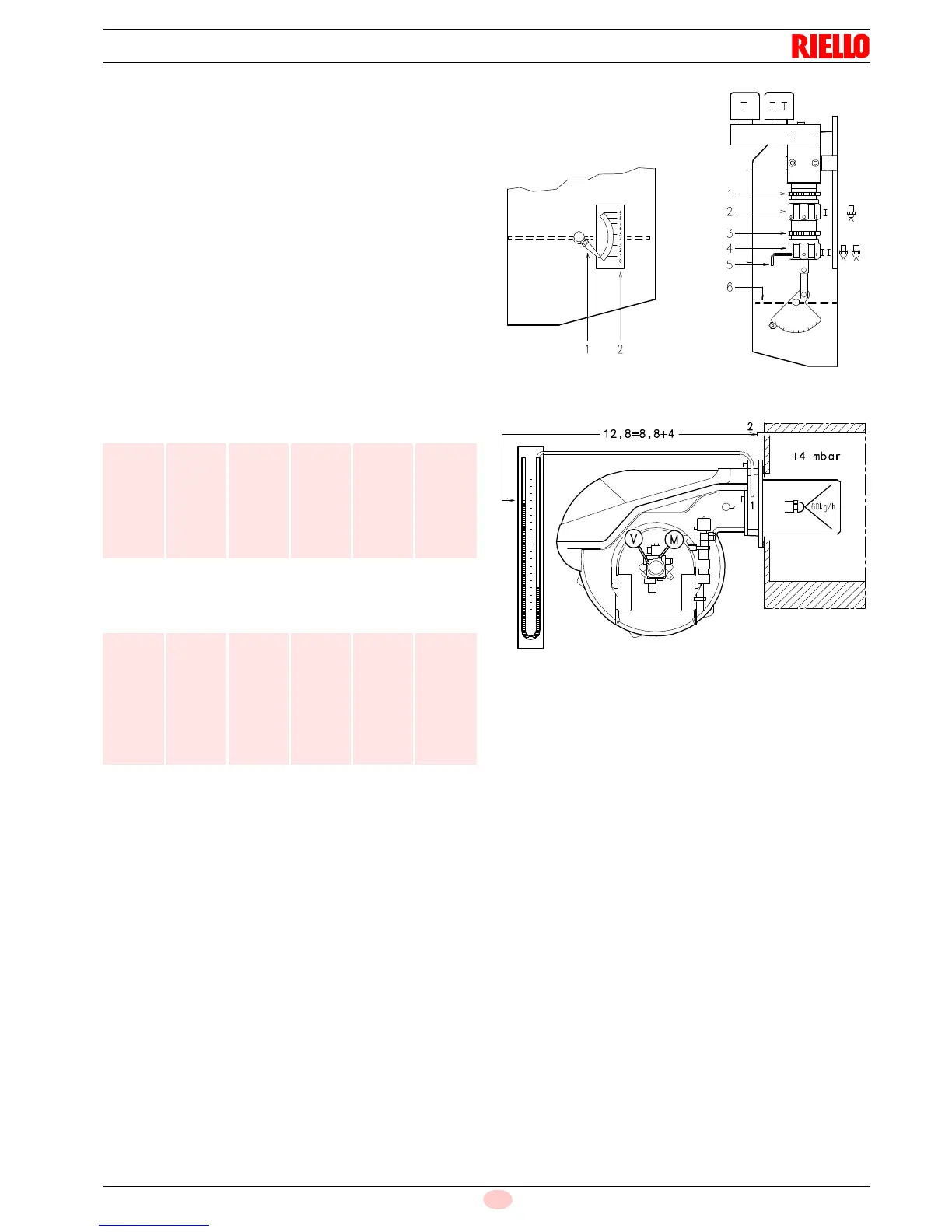

2,3 (Fig. 27) notch aligned with index 1) (Fig. 27).

When the adjustment is terminated lock the hex element 2)

(Fig. 28) with the ring nut 1).

• 2nd stage fan air gate valve

Set switch 2) (Fig. 26 on page 26) to the 2nd stage position and

adjust the air gate valve 6) (B, Fig. 27) by turning the hex element

4) (B, Fig. 27), after having loosened the ring nut 3)(B, Fig. 27).

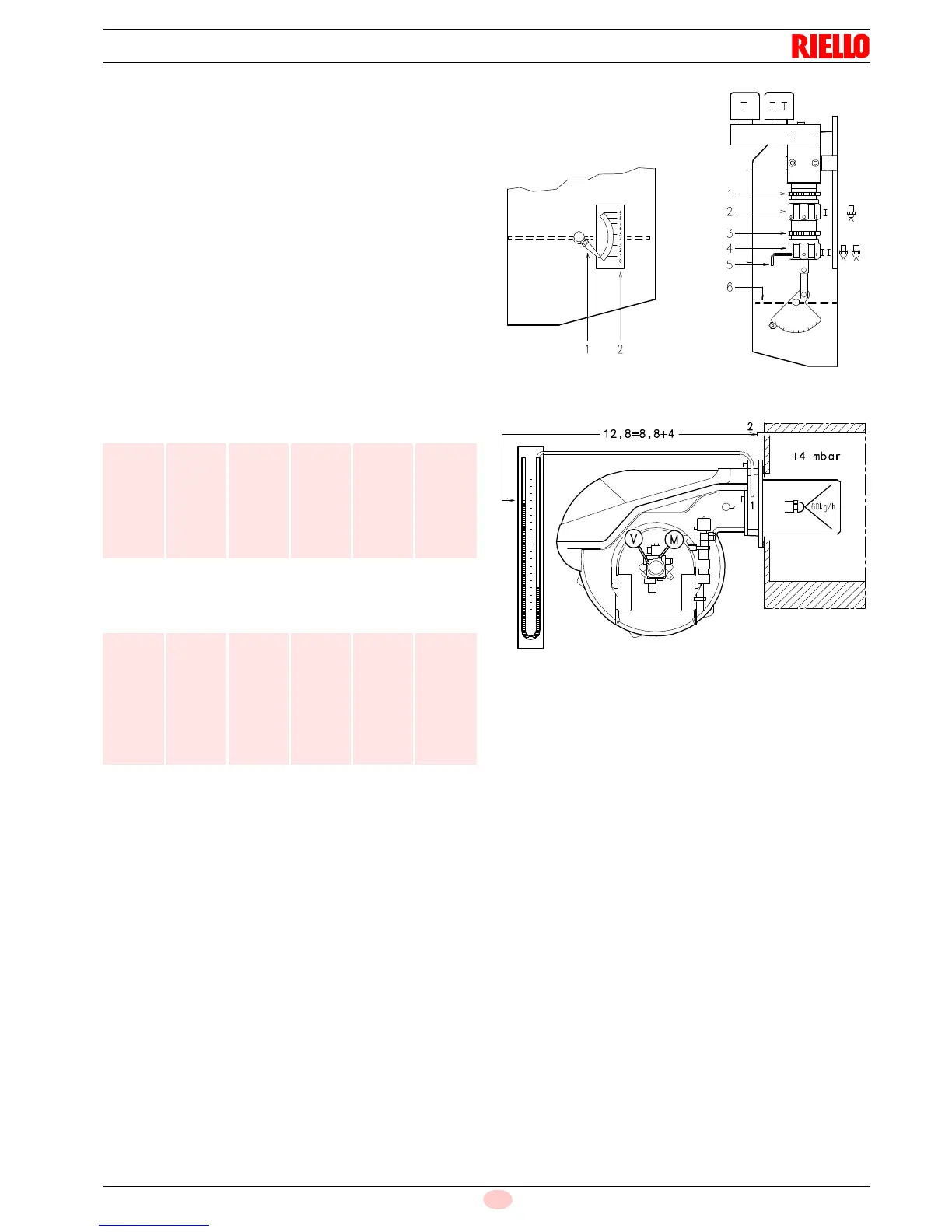

Air pressure at attachment 1) (Fig. 28) must be approximately the

same as the pressure specified in (Tab. N) plus the combustion

chamber pressure measured at attachment 2).

Refer to the example in the adjacent figure.

in order to facilitate adjustment of hex elements 2) and 4) (A,

Fig. 27), use a 3 mm Allen key 5) (B, Fig. 27).

Gas oil

Kerosene

(1) With shutter 4) (Fig. 12 on page 17) retracted

mbar = air pressure in 1) with zeropressure in 2)

Tab. N

RL 70 RL 100 RL 130

kg/h mbar kg/h mbar kg/h mbar

40

50

60

70

8.5

8.6

8.8

9.2

60

70

80

90

100

7.2

7.7

8.4

9.3

11.0

80

90

100

110

120

130

130

7.0

7.2

7.6

8.1

9.0

11.0

8.5

(1)

RL 70 RL 100 RL 130

kg/h mbar GPH mbar kg/h mbar

40

45

50

55

60

70

7.2

7.4

7.7

8.0

8.2

8.3

58

65

73

80

86

99

6.8

7.1

7.5

8.2

9.8

11.3

80

90

95

100

115

120

130

130

7.5

7.9

8.1

8.5

9.8

10

12.4

8.5

Loading...

Loading...