Dear Customer,

Thank you for choosing a machine from the Ritmo S.p.A. range of products.

This manual and its enclosure have been prepared by the manufacturer for the purpose of illustrating the features and usage of the

ELEKTRA electrofusion control unit. They contain all the information and recommendations you need for the safe and proper use of the

equipment by trained welders. We urge you to read completely both the manual and its enclosure before using the welding equipment.

We also advise you to keep these papers with the machine for future reference and/or eventual next users.

We are sure that you will soon become familiar with your equipment and that it will give you many years of entirely satisfactory service.

With best wishes,

Ritmo S.p.A.

1. FIELD OF APPLICATION

ELEKTRA is a multi-purpose electro-fusion control unit that connects PE and PP pipes by fittings/couplers heated by electric current.

ELEKTRA is built according to ISO 12176-2, ISO 12176-3, ISO 12176-4.

ELEKTRA can recognize fitting/coupler bar codes according to ISO 13950, define its welding parameters and store, print or download

welding reports to USB stick.

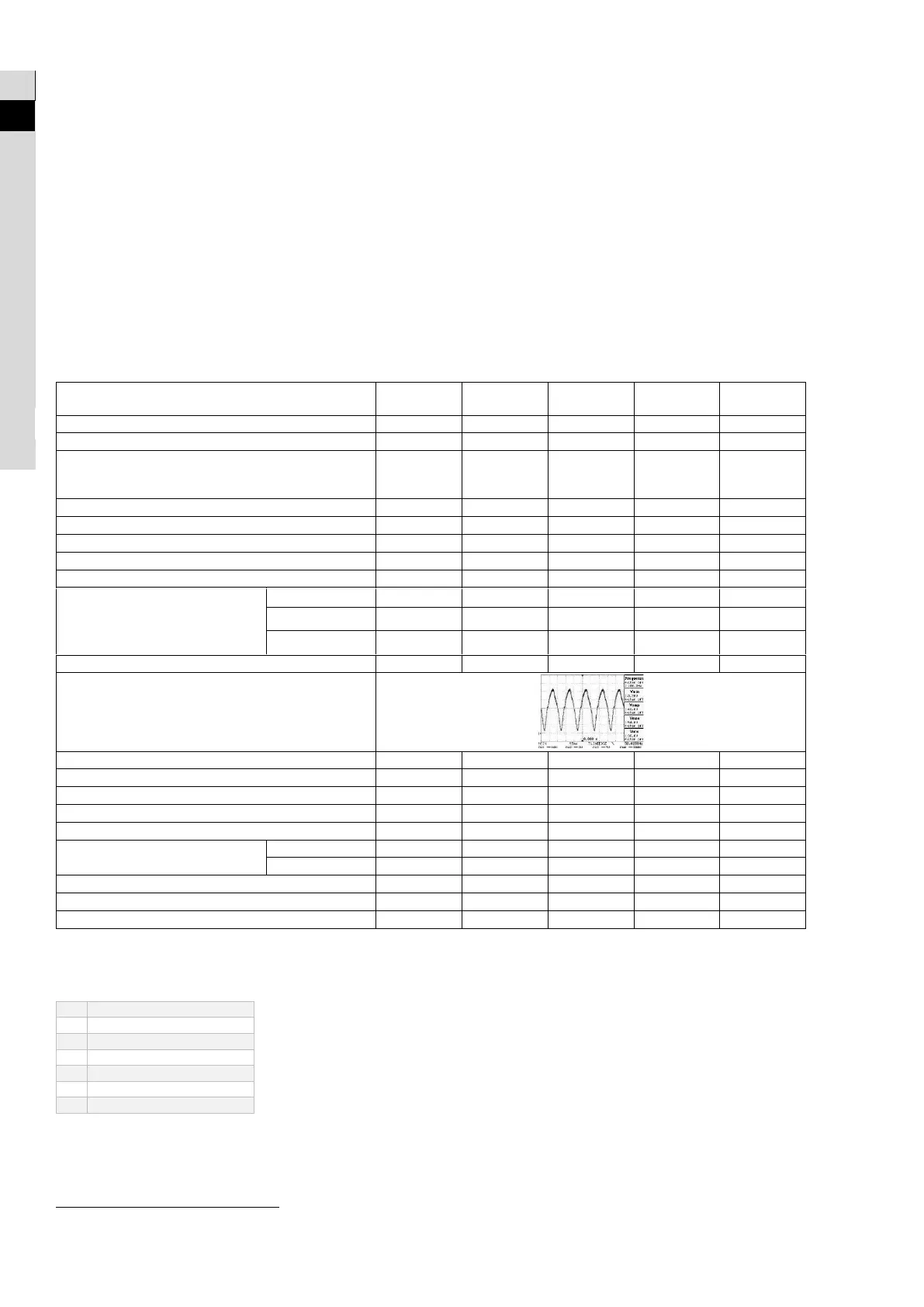

2. TECHNICAL SPECIFICATIONS

ACCESSORIES: GPS, PRINTER

3. PARTS, DIMENSIONS, WEIGHT on page 108

Loading...

Loading...