5. GENERAL WELDING CRITERIA

The quality of the joint depends on your scrupulous compliance

with the following recommendations.

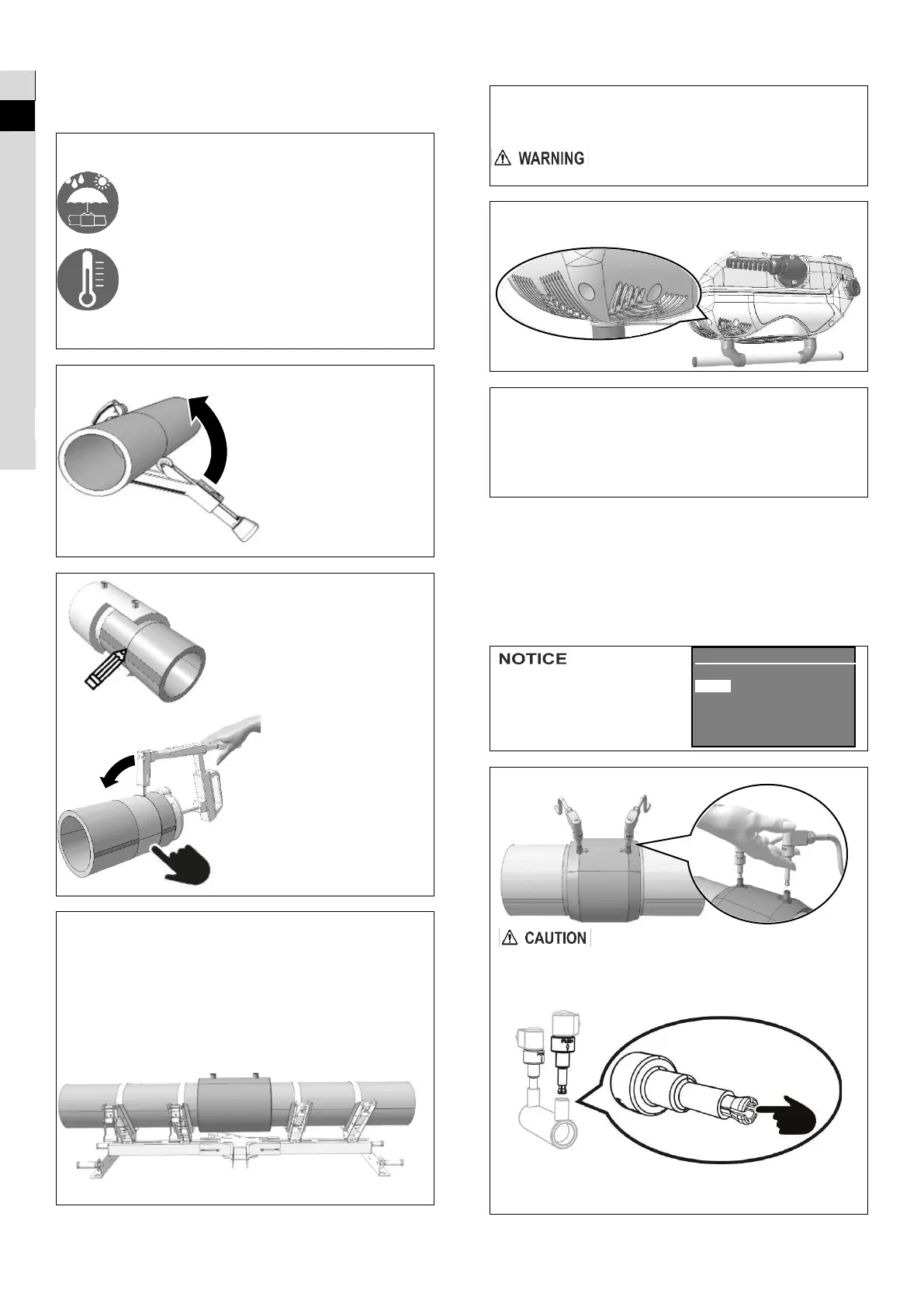

HANDLING THE PIPES AND COUPLERS

During welding, the pipes and couplers must be at

near-ambient temperature, as detected by the

welder’s temperature probe. They must

consequently be protected from direct sunlight

both before and during welding, since they could

otherwise become much warmer than the

ambient temperature, with a consequent

negative effect on the electro-melting process

(i.e. excessive melting of the pipe and coupler).

In the case of excessively high temperatures,

move the pipes and coupler to a cool, shady

place and wait for their temperature to return to

near-ambient values.

Cut the ends of the pipes

being prepared for welding

at right-angles, using

suitable pipe-cutting tools.

Pay attention to avoid both

bending and ovalizing of

the pipe.

Make sure to obtain an

even, overall scraping

action extending over at

least 1 cm for each half of

the coupler.

Scraping with sandpaper,

rasps, or emery grinding

wheels is absolutely

unsuitable.

Smoothly scrape off the

oxidized surface layer from

the pipe using suitable tools.

Remove the coupler from its packaging only just before it is

used and clean the inside of the coupler in compliance with

the manufacturer’s instructions.

Slide the ends of the pipes into the coupler. It is advisable to

align the pipe and couplers in order:

• to ensure that the parts remain in a stable position

throughout the welding and cooling phases;

• to avoid any mechanical strain on the joint during the

welding and cooling phases.

An aligning device can be used to achieve optimal aligning.

The welding must be performed as soon as possible after the

cleaning Pipes and fittings must be made of the same polymer

or compatible substances. Compatibility between polymer has

to be stated by the manufacturer.

Never weld a coupler twice.

Check that no water has accumulated in the product and, if

necessary, turn the machine so that the water comes out of

the ventilation grille.

The cooling time varies, depending on the diameter of the

couplers and the ambient temperature. Always comply with

the cooling-time recommendations given by the couplers’

manufacturer.

The removal of the aligning devices and disconnection of the

welding cables must be done only after the cooling phase has

come to a complete end.

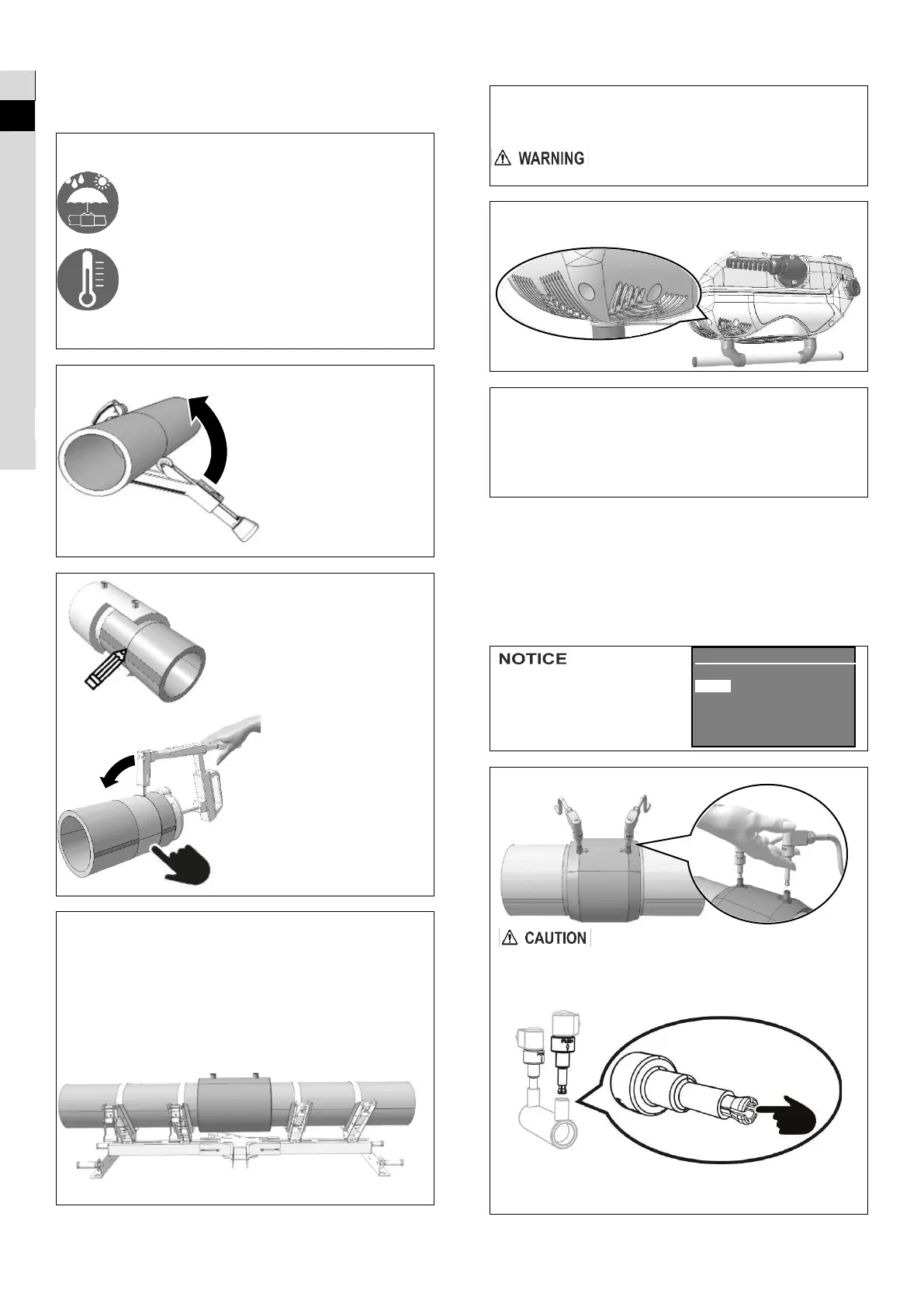

6. OPERATING INSTRUCTIONS

PREPARATION

Prepare the pipes and the coupler for welding in compliance

with the recommendations given in the “General Welding

Criteria” section of this manual and furthermore the

recommendations of the coupler’s manufacturer.

SETUP

Connect the equipment to the mains and turn on the main

switch.

when the Elektra is

switched on for the very first time,

the picture on the right-side will

show up, as some settings will be

requested (Language, Time and

Date format STARTUP Seite 109).

Connect the leads to the coupler.

The terminal leads above must ensure a

good electric conductivity to avoid overheating and

eventually irreversible damages. Make sure that the terminal

leads are not dirty nor clogged. Clean them if necessary.

Loading...

Loading...