It allows to setup some specific

parameters through 4-digit

numbers (codes).

Use ▲ and ▼ buttons to change

the digit value and OK ►button to

move to the next digit.

Codes available to the user are on

page 19.

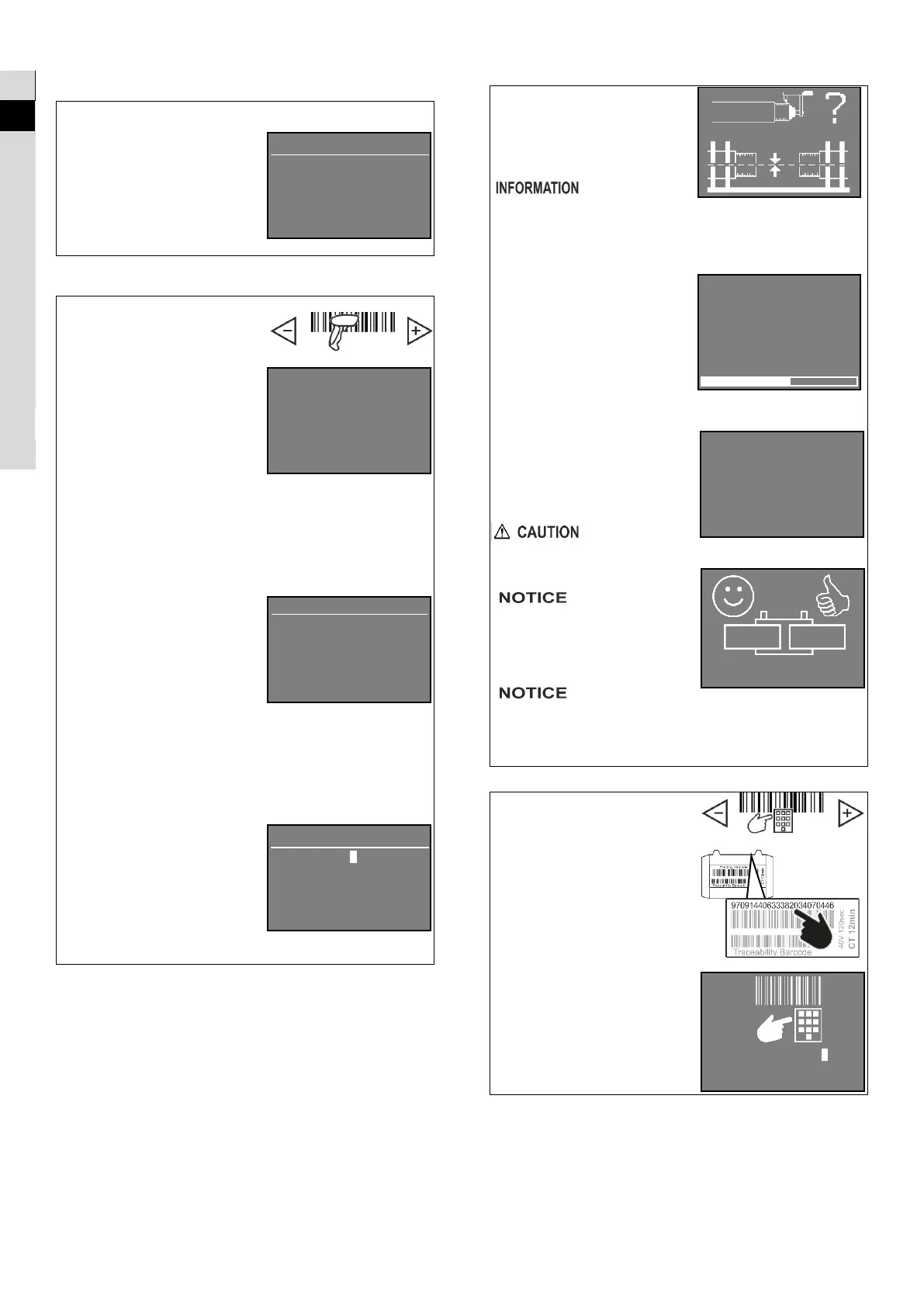

WELDING THROUGHT BAR CODE READING

Connect the BARCODE reader

and select the “READ BARCODE”

1. Read the Welding barcode

Keep the trigger pressed and make

sure the LASER beam points out the

welding bar code.

Displayed parameters:

Junction type e.g. I CPL PI

Voltage & Time e.g. 39.5V 100s

Diameter e.g. 32 mm

Cooling Time CT e.g. 10 min

Note: In case of barcode scanner

failure you can still set the welding

parameters manually (below).

Press OK ► to proceed.

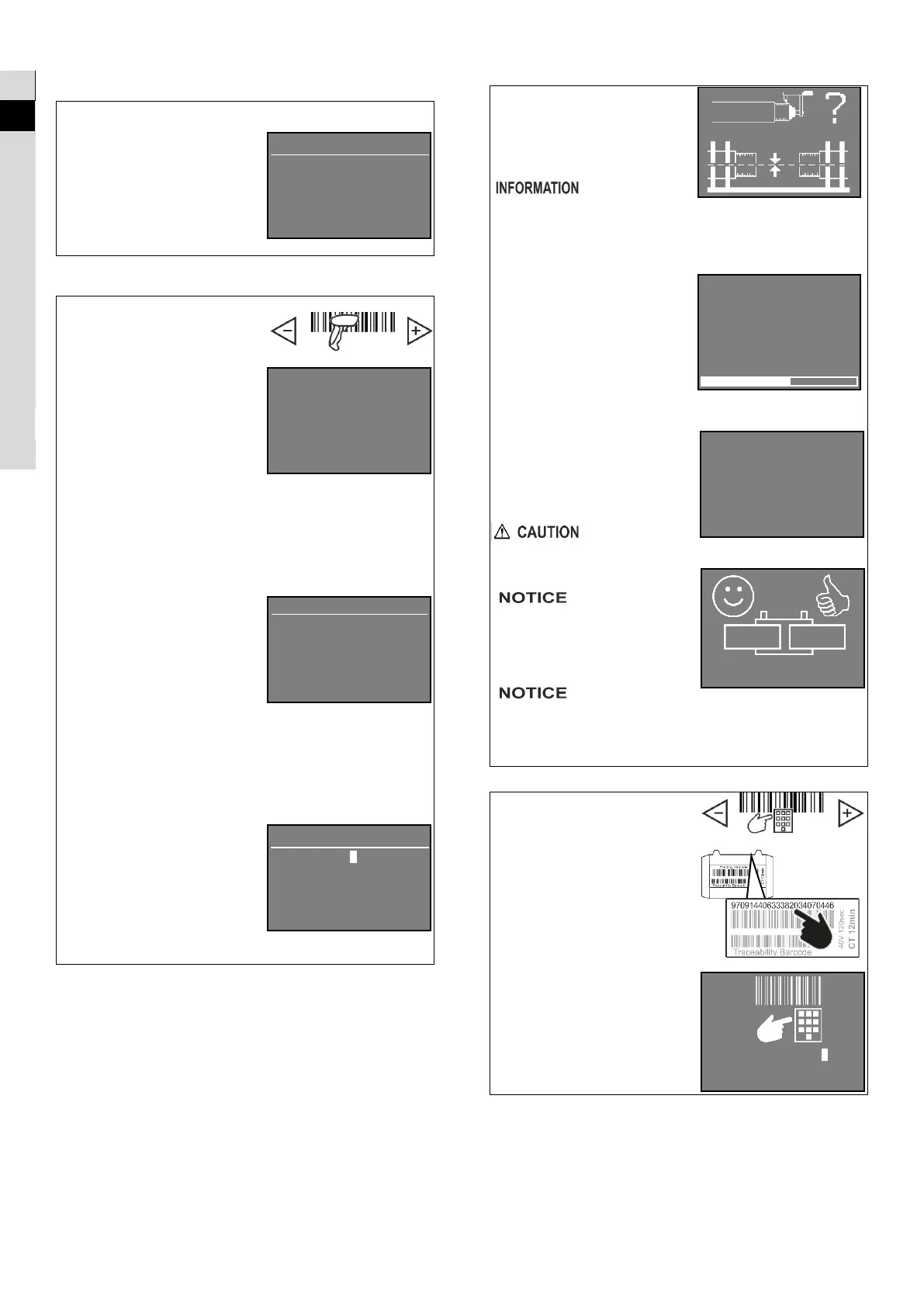

2. Read the Traceability barcode

If Traceability option is enabled,

the Elektra will prompt to read

traceability barcodes.

Note: the traceability barcodes are

up to 3, i.e. 1 coupler and 2 pipes.

In order to skip a traceability

barcode, press the OK ► button.

Keep the trigger pressed and make

sure the LASER beam points out the

traceability bar code.

The main bar code data will be

presented as in the example on the

right side.

Press OK ► to proceed.

3. Add a Note

If Note option is enabled, the

Elektra will prompt to type in some

note text.

Use ▲ and ▼ buttons to change

the digit value and OK ►button to

move to the next digit.

Hold OK ►button to store or move

to the last digit and press OK ►

4. Scraping and Aligning

The pictures on the right side

shows up as a reminder of the

pipes’ scraping and alignment

required before welding (on

page 16).

poor scraping and

alignment may compromise the

quality of the welded joint even

though the welding process was

carried out correctly.

Press OK ► to start the welding.

5. Welding

The heating phase starts.

The display will show the

countdown till the welding

process is accomplished.

6. Cooling

After completion of the heating

phase, the display shows the

cooling status.

When the cooling countdown is

over, the Elektra beeps.

The leads can be disconnected

and the Elektra switched off.

don’t move or

strain the joint during the cooling

phase. Wait till the cooling time

has elapsed.

the Elektra does

not perform a leak test on the

welded joint. The Elektra only

shows that all the welding phases

have been correctly

accomplished.

Ritmo S.p.A

disclaims all liability for defective

welded joints made without

regard to proper preparation of

the pipes end to be welded.

WELDING THROUGHT MANUAL INPUT OF BAR CODE

Select the “BARCODE MANUAL”

mode and

press OK ►.

1. Type the welding barcode

digits

Use ▲ and ▼ buttons to change

the digit value and OK ►button to

move to the next digit.

2. Follow the steps of

WELDING THROUGHT BAR CODE

READING

TEXT TO STORE

_ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _

32 mm SDR: 11

32mm

PE100 MFR not spec.

39.5V 100s

32mm

[CT] 10 min

9 7 0 9 1 4 4 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0

Loading...

Loading...