Rolls- Royce Silver Shadow

6

Bentley

T

Series

Workshop

hnua/

C

chapter

J

washer which must

be

fitted between the belleville

washers and the bearing, to give the

correct pre-load.

Adjusting washers are available in a range from

0.200 in. to 0.260 in. (5,08

mm

to

6.60

mm.)

in

increments of

0.010 in.

(0,254

mm.).

Washers my

be

lightly ground to obtain the correct dimension but

if this is done, equal amounts must

be

removed from

each side and the washer must

be

kept bt and

parallel.

28.

Fit the right-hand side housing to the half-shaft.

29.

Fit the correct washer

with

the chamfered side

outward. Fit the three belleville washers, convex

side outward, fit the distance piece, housing and half-

shaft assembly after applying a light coating of

SQ

32M jointing compound to the flange faces.

30.

Tighten the housing securing nuts progressively

and evenly and

hally torque tighten them

in

accord-

ance with the standard figures, relative to size, given

in

Chapter

P.

31.

Torque tighten the nuts securing the two large

bearing caps

in

accordance with the standard figures

given in Chapter

P.

32.

Remove the stiffening bar

(RH

8032), fit the

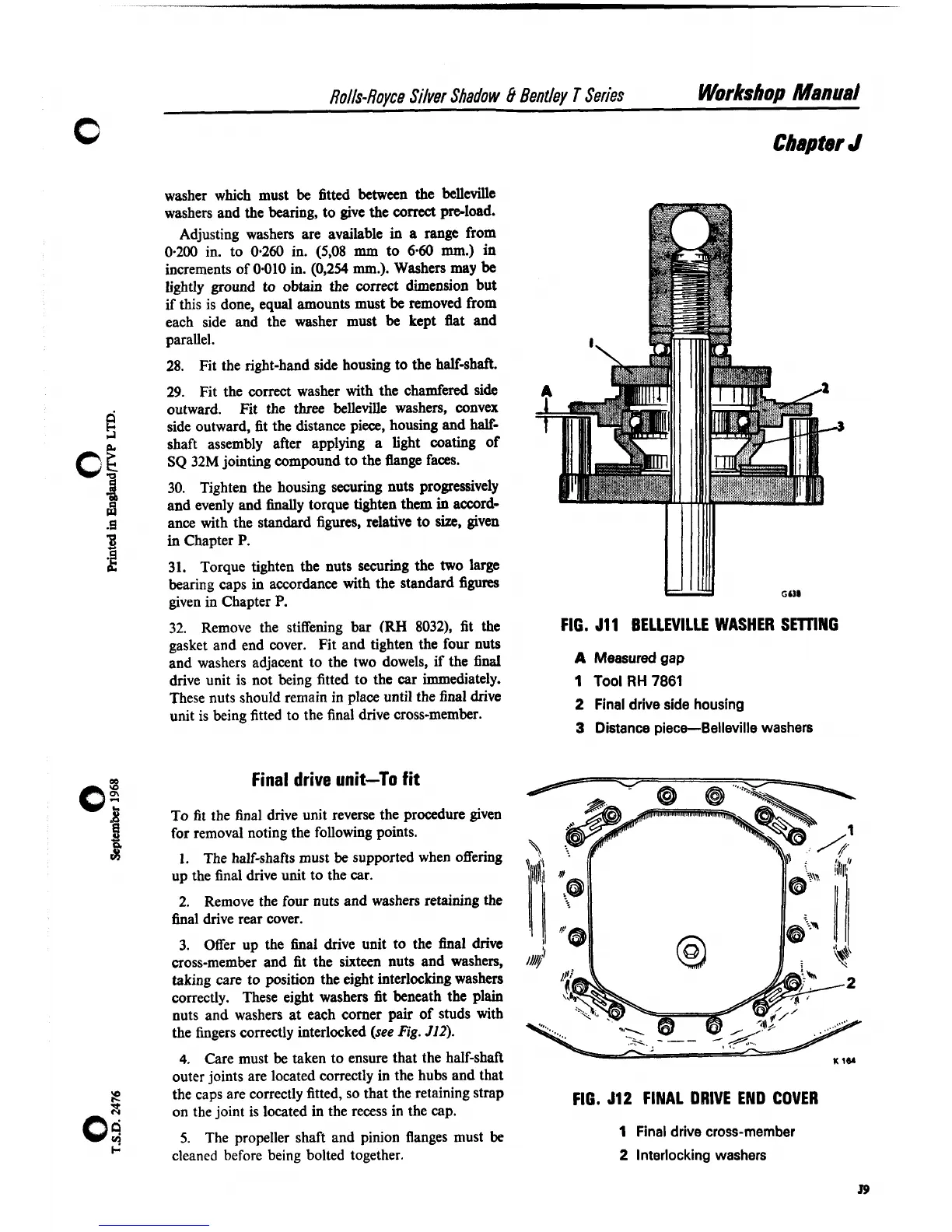

FIG.

J11

BELLEVILLE WASHER SETnNG

gasket and end cover. Fit and tighten the four nuts

and washers adjacent to the two dowels, if the final

A

Measured gap

drive unit is not being fitted to the car immediately.

1

Tool

RH

7861

These nuts should remain in place until the final drive

2

Final drive side housing

unit is being fitted to the final drive cross-member.

3

Distance piece--Belleville washers

Final

drive

unit-To fit

0".

1

To fit the final drive unit reverse the procedure given

3

for removal noting the following points.

a

1.

The half-shafts must be supported when offering

up the final drive unit to the car.

2.

Remove the four nuts and washers retaining

the

final drive rear cover.

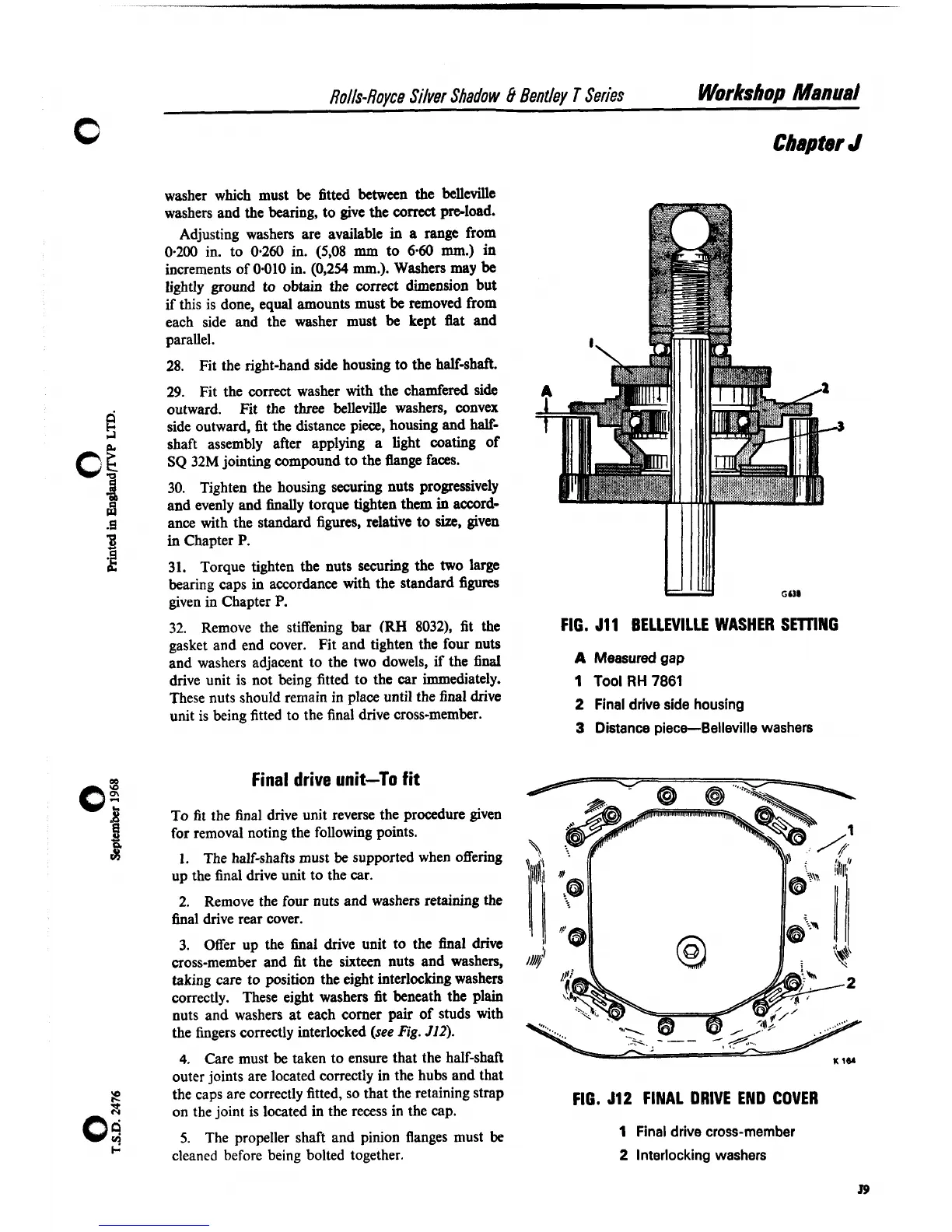

3.

Offer up the final drive unit to the ha1 drive

cross-member and fit the sixteen nuts and washers,

taking care to position the eight interlocking washers

correctly. These eight washers fit beneath the plain

nuts and washers at each comer pair of studs with

the fingers correctly interlocked

(see

Fig.

512).

4.

Care must

be

taken to ensure that the half-shaft

outer joints are located correctly in the hubs and that

2

the caps are correctly fitted, so that the retaining strap

on the joint is located in the recess in the cap.

FIG.

512

FINAL DRIVE END COVER

0;

5.

The propeller shaft and pinion flanges must

be

1

Final drive cross-member

I-

cleaned before being bolted together.

2

Interlocking washers

Loading...

Loading...