Rolls-Royce Silver

Shadow

8

Bentley

T

Series

Workshop Manual

Chapter

K

22.

Disconnect the fuel feed pipe from the float

chambers.

23.

Cars from Car Serial Number SRH 8742 and

onwards.

Remove the weakening device pipes

24.

Disconnect the carburetter spill

F,;e

from the

float chambers.

25.

Remove the float chamber lids and floats keeping

them identified for their respective carburetters.

26.

Remove the nut securing the throttle damper (if

fitted) to its bracket; remove the damper.

27.

Remove the throttle spring.

28.

Completely remove the two pinch bolts securing

the levers to the

'A'

and

'B'

bank carburetter butterfly

valve spindles; remove the levers.

29.

Remove the nuts and washers securing both

carburetters to the 'Tee' piece; remove the carburetters

together with the throttle damper bracket (if fitted)

adjacent to

'A'

bank carburetter.

Carburetter-To dismantle

(see

Fig.

KI2)

1.

Thoroughly clean the outside of the carburetter.

Important

Parts from the two carburetters

should not be interchanged. To

prevent this, the parts as they are

removed from each carburetter,

should be placed in two boxes,

preferably marked

'A'

bank and

'B'

bank.

2.

Unscrew and remove the damper and washer

from the suction chamber lid.

3.

Remove the suction chamber retaining screws

and remove the chamber without tilting it.

4.

Remove the piston spring.

5.

Carefully lift out the piston and needle assembly;

empty the damper oil from the piston rod.

For carburetters fitted

with

a fixed needle carry out

Operation

6

(see

Fig.

K17).

6.

Remove the needle locking screw and withdraw

the needle from the piston. If it cannot easily be

removed, first tap the needle inwards then pull out-

wards. Do not bend the needle.

If excessive force is

required to remove the needle it should be discarded

and a new one fitted.

For carburetters fitted with a spring loaded needle

and

centralised jet carry out Operations

7

and

8

(see

Fig.

KI8).

7.

Remove the needle guide locking screw from the

piston and withdraw the needle assembly taking care

not to bend the needle.

8.

Withdraw the needle guide from the needle and

remove the spring.

Note

The flange collar pressed onto the jet

needle isire-set at the factory and must

not be disturbed.

9.

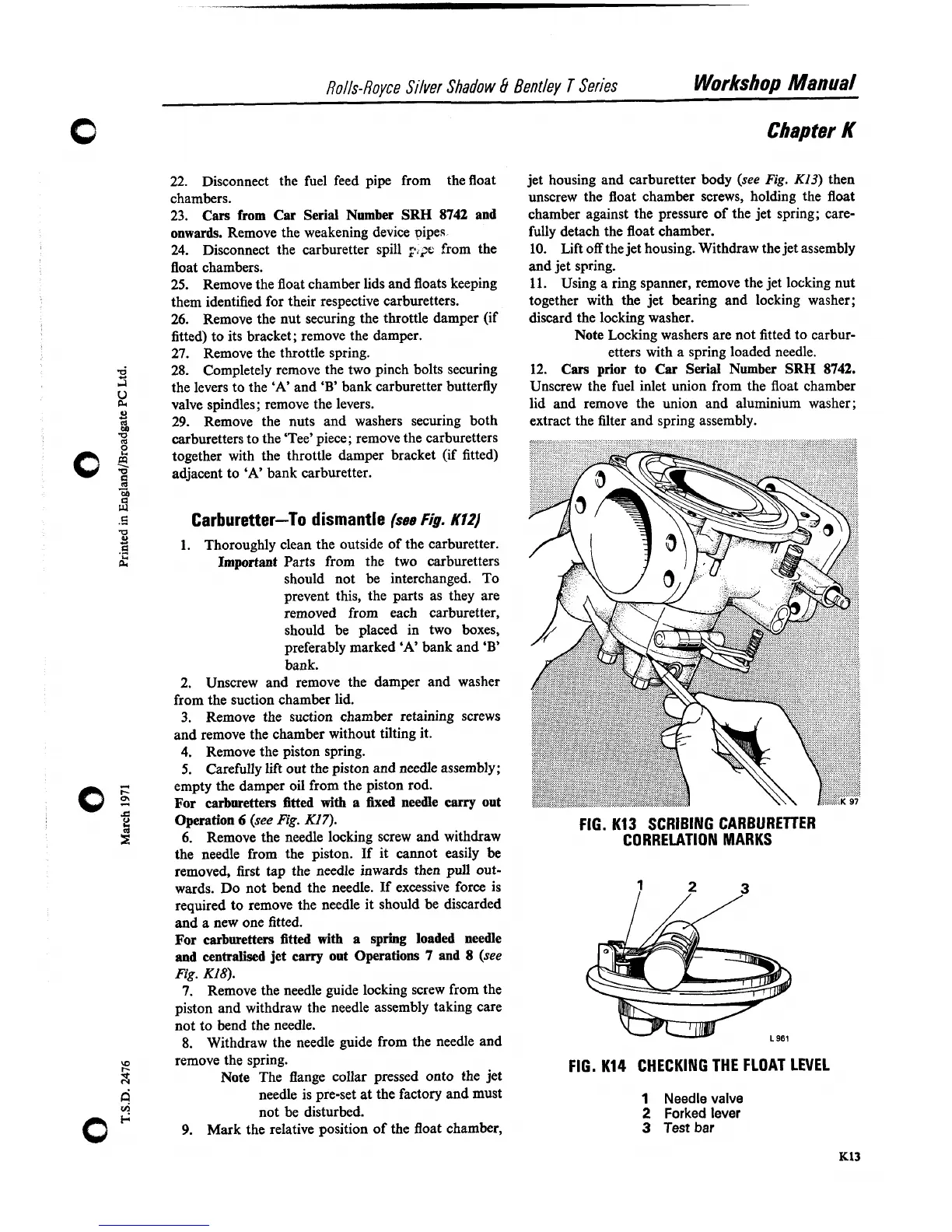

Mark the relative position of the float chamber,

jet housing and carburetter body (see

Fig.

K13)

then

unscrew the float chamber screws, holding the float

chamber against the pressure of the jet spring; care-

fully detach the float chamber.

10.

Lift

off

the jet housing. Withdraw the jet assembly

and jet spring.

11.

Using a ring spanner, remove the jet locking nut

together with the jet bearing and locking washer;

discard the locking washer.

Note

Locking washers are not fitted to carbur-

etters with a spring loaded needle.

12.

Cars prior to Car Serial Number SRH 8742.

Unscrew the fuel inlet union from the float chamber

lid and remove the union and aluminium washer;

extract the filter and spring assembly.

FIG.

K13

SCRIBING CARBURETTER

CORRELATION MARKS

7

2

,

3

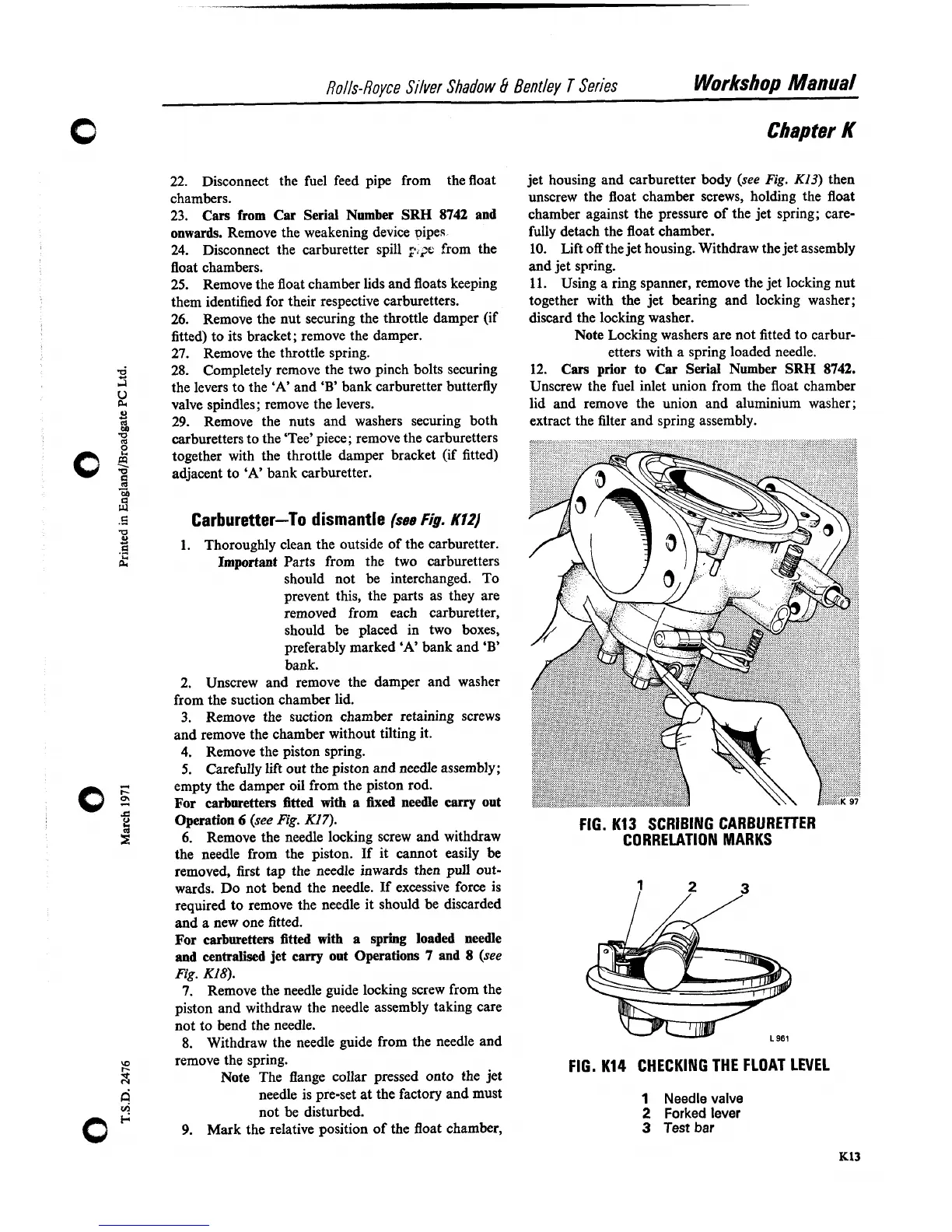

FIG.

K14

CHECKING

THE FLOAT LEVEL

1

Needle valve

2

Forked lever

3

Test

bar

Loading...

Loading...