Workshop

Manual

Rolls- Royce Silver Shadow

&

Bentley

T

Series

Chapter

M

Field coils-To remove

Commutator end bearing-To fit

1.

Remove the rivet securing the field coil

1.

Pack the new bearing with high melting point

terminal block to the generator casing.

grease.

2.

Unsolder the field coil connections.

2.

Press the bearing into position on the shaft,

3.

Remove the insulator which is provided to

pressure should only be exerted on the inner race

prevent the junction of the field coils from contacting of the bearing during this operation.

the generator casing.

3.

Fit a new tab-washer.

4.

Mark the casing and pole shoes so that the

latter can be fitted in their original positions.

5.

Using a wheel operated screwdriver, unscrew

the two pole shoe securing screws.

6.

Draw the pole shoes and coils out of the

casing; remove the coils from the pole shoes.

Brushes-TO bed in

Field coils-To fit

I.

Fit the new field coils over the pole shoes and

position inside the casing. Take care to ensure that

the taping of the field coils is not trapped between

the pole shoes and the casing.

2.

Locate the pole shoes and field coils by lightly

tightening the fixing screws. Using the wheel

operated screwdriver, fully tighten the screws.

3.

Fit the insulation piece between the field coil

connections and the casing.

4.

Solder the field connections to the field coil

terminals block; rivet the terminal block to the

generator casing.

Drive-end bearing-To remove

1.

Withdraw the screws securing the bearing

retaining plate to the end bracket; remove the plate.

2.

Press out the bearing.

Drive-end bearing-To fit

1.

Pack the new bearing with a high melting point

grease.

2.

Locate the bearing in the end-bracket housing

and press into position.

3.

Fit the bearing retaining plate and tighten the

securing screws. Lock each screw ,by centre

punching the screw end at three equally spaced

points.

Commutator end bearing-To remove

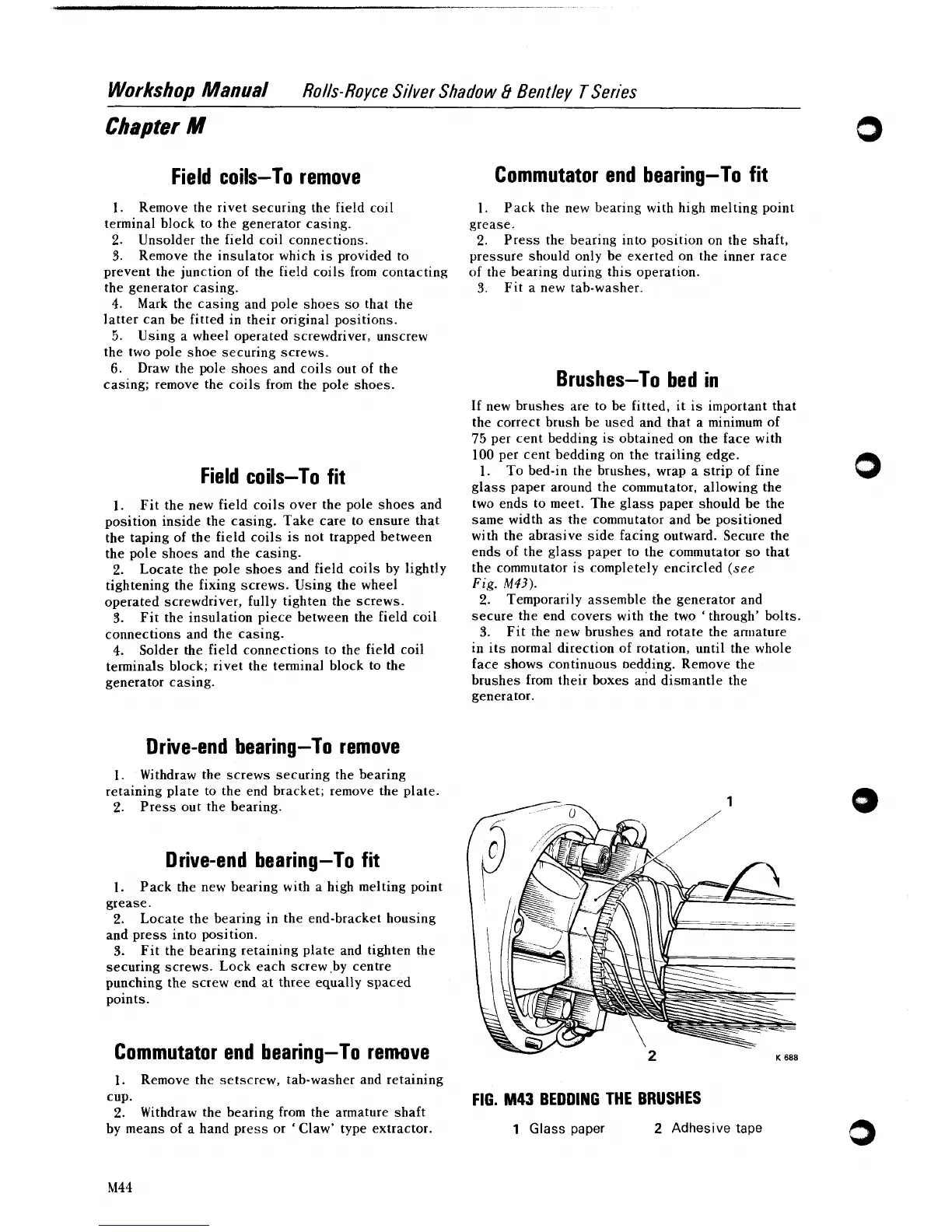

If new brushes are to be fitted, it is important that

the correct brush be used and that a minimum of

75

per cent bedding is obtained on the face with

100

per cent bedding on the trailing edge.

1.

To bed-in the brushes, wrap a strip of fine

glass paper around the commutator, allowing the

two ends to meet. The glass paper should be the

same width as the commutator and be positioned

with the abrasive side facing outward. Secure the

ends of the glass paper to the commutator so that

the commutator is completely encircled

(see

Fig.

M43).

2.

Temporarily assemble the generator and

secure the end covers with the two 'through' bolts.

3.

Fit the new brushes and rotate the arrnature

in its normal direction of rotation, until the whole

face shows continuous oedding. Remove the

brushes from their boxes and dismantle the

generator.

1.

Remove the setscrew, tab-washer and retaining

cup.

2.

Withdraw the bearing from the armature shaft

FIG.

M43

BEDDING THE BRUSHES

by means of a hand press or

'

Claw' type extractor.

1

Glass

paper

2

Adhesive tape

Loading...

Loading...