Rolls-Royce Silver Shadow

&

Bentley

T

Series

Worksho~

Manual

Chapter

P

Chapter

P

TORQUE TIGHTENING FIGURES

5

6

c

.-

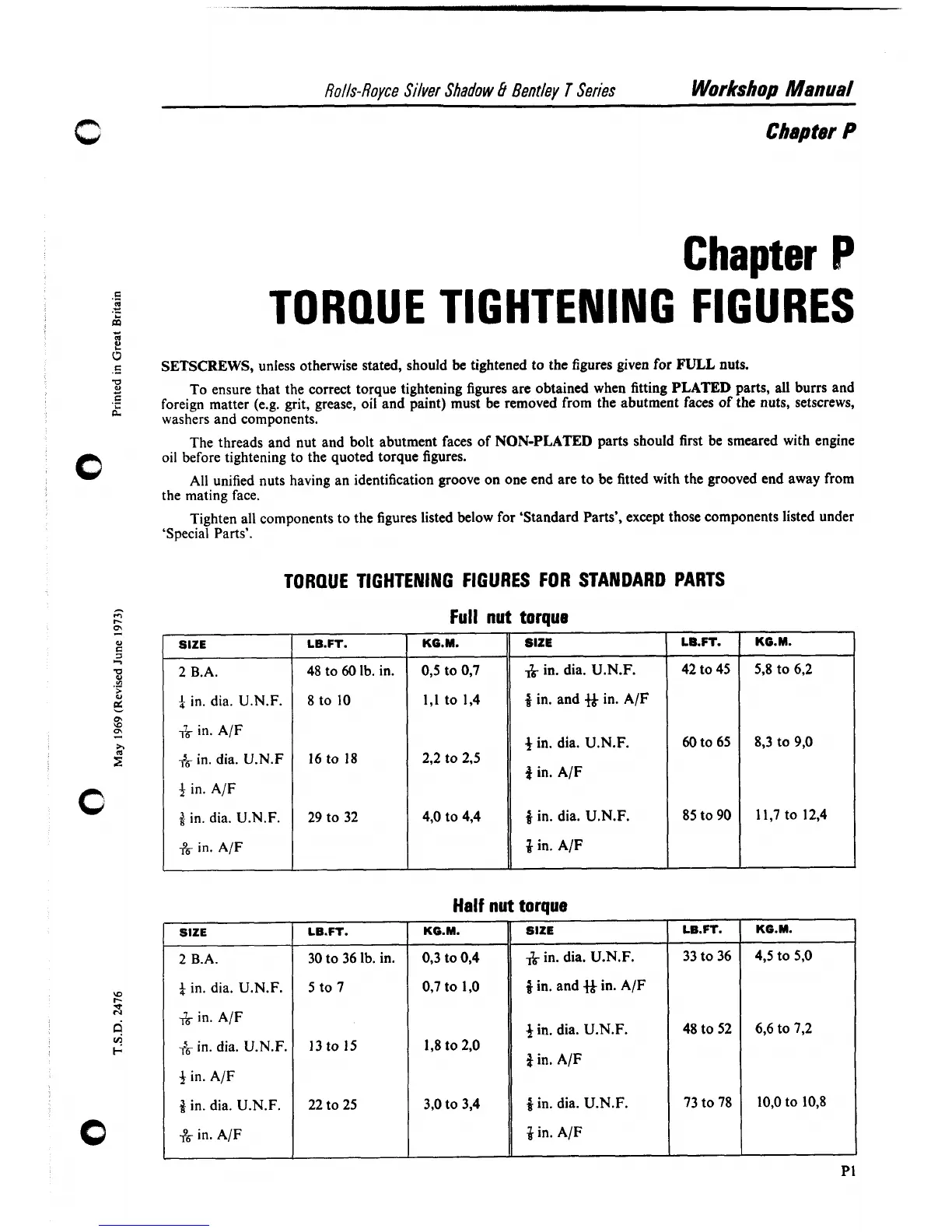

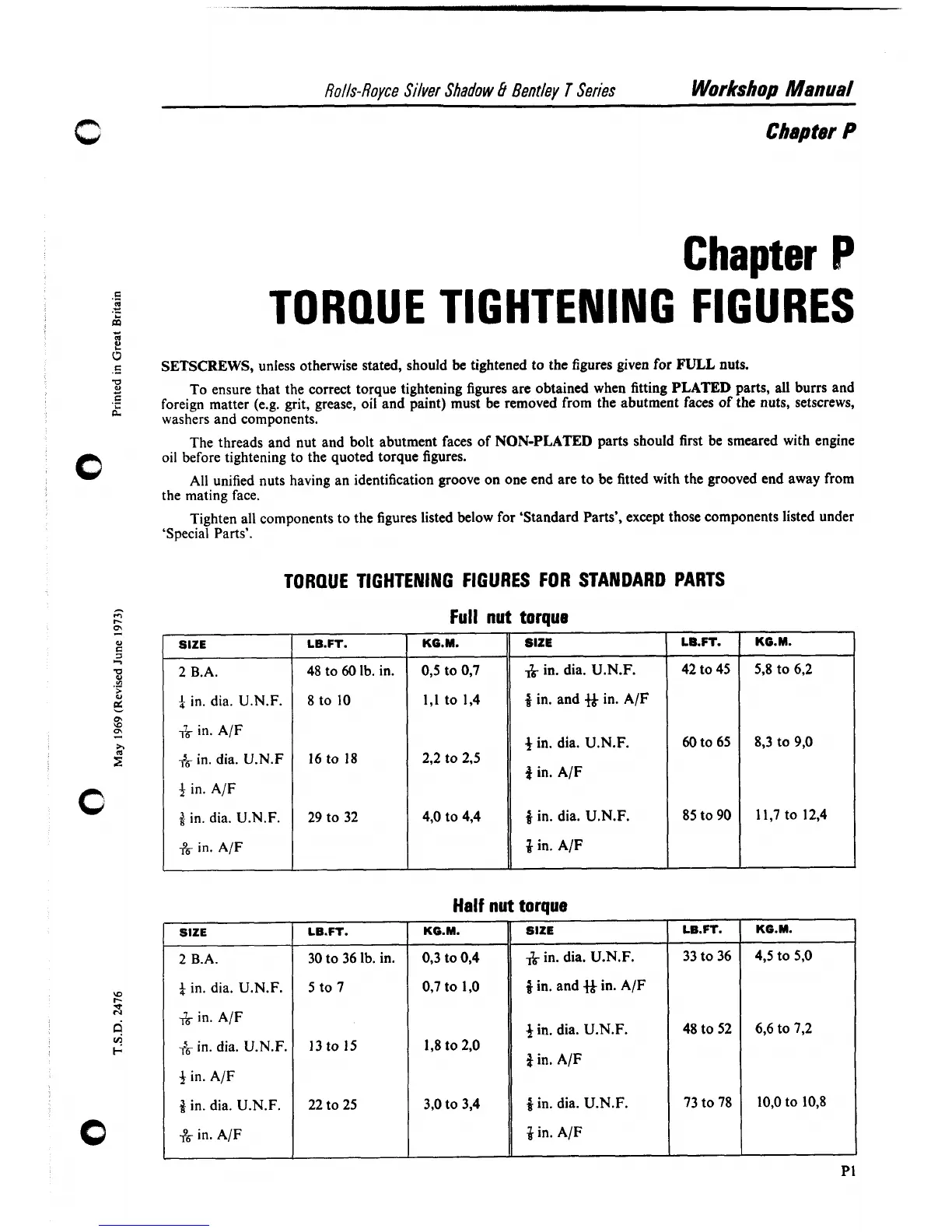

SETSCREWS,

unless otherwise stated, should

be

tightened to the figures given for

FW,L

nuts.

B

*

C

To ensure that the correct torque tightening figures are obtained when fitting PLATED parts, all burrs and

.-

foreign matter (e.g. grit, grease, oil and paint) must be removed from the abutment faces of the nuts, setscrews,

li

washers and components.

The threads and nut and bolt abutment faces of

NON-PLATED parts should first be smeared with engine

0

oil before tightening to the quoted torque figures.

All unified nuts having an identification groove on one end are to be fitted with the grooved end away from

the mating face.

Tighten all components to the figures listed below for 'Standard Parts', except those components listed under

'Special Parts'.

TORQUE TIGHTENING FIGURES FOR STANDARD PARTS

Full nut torque

Half nut torque

KG.M.

5,8 to 6,2

8,3 to

9,O

11,7to12,4

LB.FT.

42 to 45

60 to 65

85to90

KG.M.

4,5 to 5,O

6,6 to 7,2

10,O to 10,8

SIZE

&

in. dia. U.N.F.

4

in. and

+&

in. A/F

+

in. dia. U.N.F.

4

in. A/F

4

in. dia. U.N.F.

4

in. A/F

SIZE

2 B.A.

J,

in. dia. U.N.F.

TZg

in. A/F

-&

in. dia. U.N.F

3

in. A/F

$

in. dia. U.N.F.

-&

in.

A/F

P1

LB.FT.

33 to 36

48 to 52

73 to 78

SIZE

&

in. dia. U.N.F.

4

in. and

+&

in. A/F

3

in. dia. U.N.F.

4

in. A/F

4

in. dia. U.N.F.

4

in. A/F

LB.FT.

48 to

60

Ib.

in.

8 to 10

16 to 18

29 to 32

KG.M.

0,3 to 0,4

0.7 to

1,O

1,8 to 2,O

3,O to 3,4

SIZE

2

B.A.

$

in. dia. U.N.F.

&

in. A/F

%

in. dia. U.N.F.

-)

in. A/F

8

in. dia. U.N.F.

-&-

in. A/F

KQ.M.

0,5 to 0,7

1,l to 1,4

2,2 to 2,5

4,O to 4,4

LB.FT.

30 to 36

lb.

in.

5 to

7

13 to 15

22 to 25

Loading...

Loading...