Rolls-Rovce Silver Shadow

&

Bentley

T

Series

Workshop

Manuel

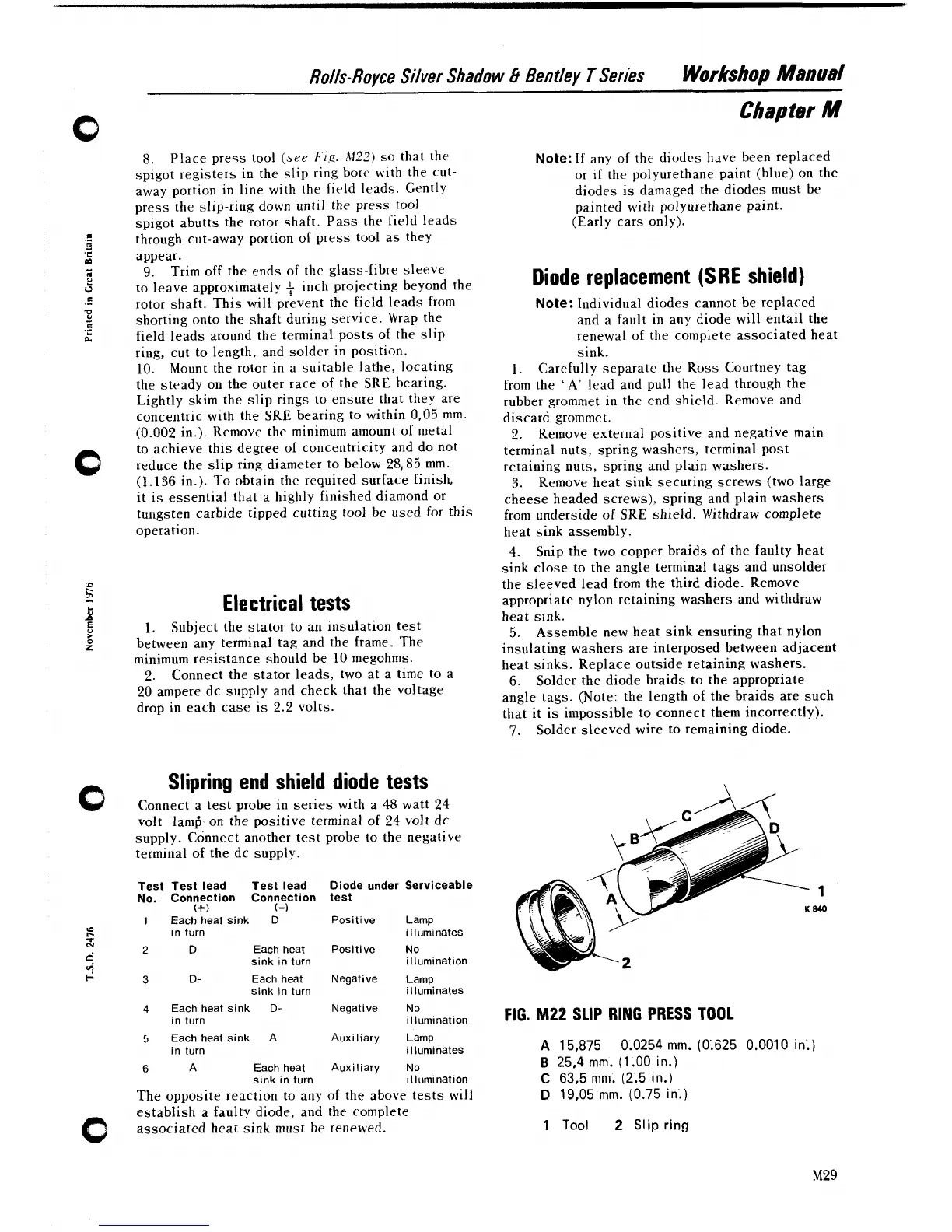

8.

Place press tool

(see

Fig.

11!2,3)

so that the

spigot registe~s in the slip ring bore with the cut-

away portion in line with the field leads. Gently

press the slip-ring down until the press tool

spigot abutts the rotor shaft. Pass the field leads

through cut-away portion of press tool as they

appear.

9.

Trim off the ends of the glass-fibre sleeve

to leave approximately

+

inch projecting beyond the

rotor shaft. This will prevent the field leads from

shorting onto the shaft during service. Wrap the

field leads around the terminal posts of the slip

ring, cut to length, and solder in position.

10.

Mount the rotor in a suitable lathe, locating

the steady on the outer race of the SRE bearing.

Lightly skim the slip rings to ensure that they are

concentric with the SRE bearing to within

0,05

mm.

(0.002 in.). Remove the minimum amount of metal

to achieve this degree of concentricity and do not

0

reduce the slip ring diameter to below 28.85 mm.

(1.136 in.). To obtain the required surface finish,

it is essential that a highly finished diamond or

tungsten carbide tipped cutting tool be used for this

operation.

Electrical tests

1.

Subject the stator to an insulation test

between any terminal tag and the frame. The

minimum resistance should be 10 megohms.

2.

Connect the stator leads, two at a time to a

20

ampere dc supply and check that the voltage

drop in each case is

2.2

volts.

Chapter

M

Note:If any of the diodes have been replaced

or

if

the polyurethane paint (blue) on the

diodes is damaged the diodes must be

painted with polyurethane paint.

(Early cars only).

Diode replacement (SRE shield)

Note: Individual diodes cannot be replaced

and a fault in any diode will entail the

renewal of the complete associated heat

sink.

1.

Carefully separate the Ross Courtney tag

from the

'

A'

lead and pull the lead through the

rubber grommet in the end shield. Remove and

discard grommet.

2.

Remove external positive and negative main

terminal nuts, spring washers, terminal post

retaining nuts, spring and plain washers.

3.

Remove heat sink securing screws (two large

cheese headed screws), spring and plain washers

from underside of SRE shield. Withdraw complete

heat sink assembly.

4.

Snip the two copper braids of the faulty heat

sink close to the angle terminal tags and unsolder

the sleeved lead from the third diode. Remove

appropriate nylon retaining washers and withdraw

heat sink.

5.

Assemble new heat sink ensuring that nylon

insulating washers are interposed between adjacent

heat sinks. Replace outside retaining washers.

6.

Solder the diode braids to the appropriate

angle tags. (Note: the length of the braids are such

that it is impossible to connect them incorrectly).

7.

Solder sleeved wire to remaining diode.

Slipring end shield diode tests

0

Connect a test probe in series with a 48 watt 24

volt

lam$ on the positive terminal of

24

volt dc

supply. Connect another test probe to the negative

terminal of the dc supply.

Test Test lead

Test lead Diode under Serviceable

No. Connection

Connection test

1

(+I

(-1

840

1

Each heat sink

D

Positive Lamp

in turn illuminates

2

D

Each heat Positive No

sink in turn illumination

3

D-

Each heat Negative Lamp

sink in turn illuminates

4

Each heat sink

D-

Negative No

in turn illumination

FIG.

M22

SLIP RING PRESS TOOL

5

Each heat sink

A

Auxiliary Lamp

in turn illuminates

A

15,875 0.0254

mm.

(0.625 0.0010

in;)

6

A

Each heat Auxiliary No

B

25,4

rnm.

(1.00

in.)

sink in turn illumination

C

63.5

mrn.

(2.5

in.)

The opposite reaction to any of the above tests will

D

19,05

rnm.

(0.75

in.)

establish a faulty diode, and the complete

0

associated heat sink must be renewed.

1

Tool

2

Slip

ring

Loading...

Loading...