Rolls-Royce Silver Shadow

&

Bentley

T

Series

workshop

Mimud

F"h4

tw

Chapter

N

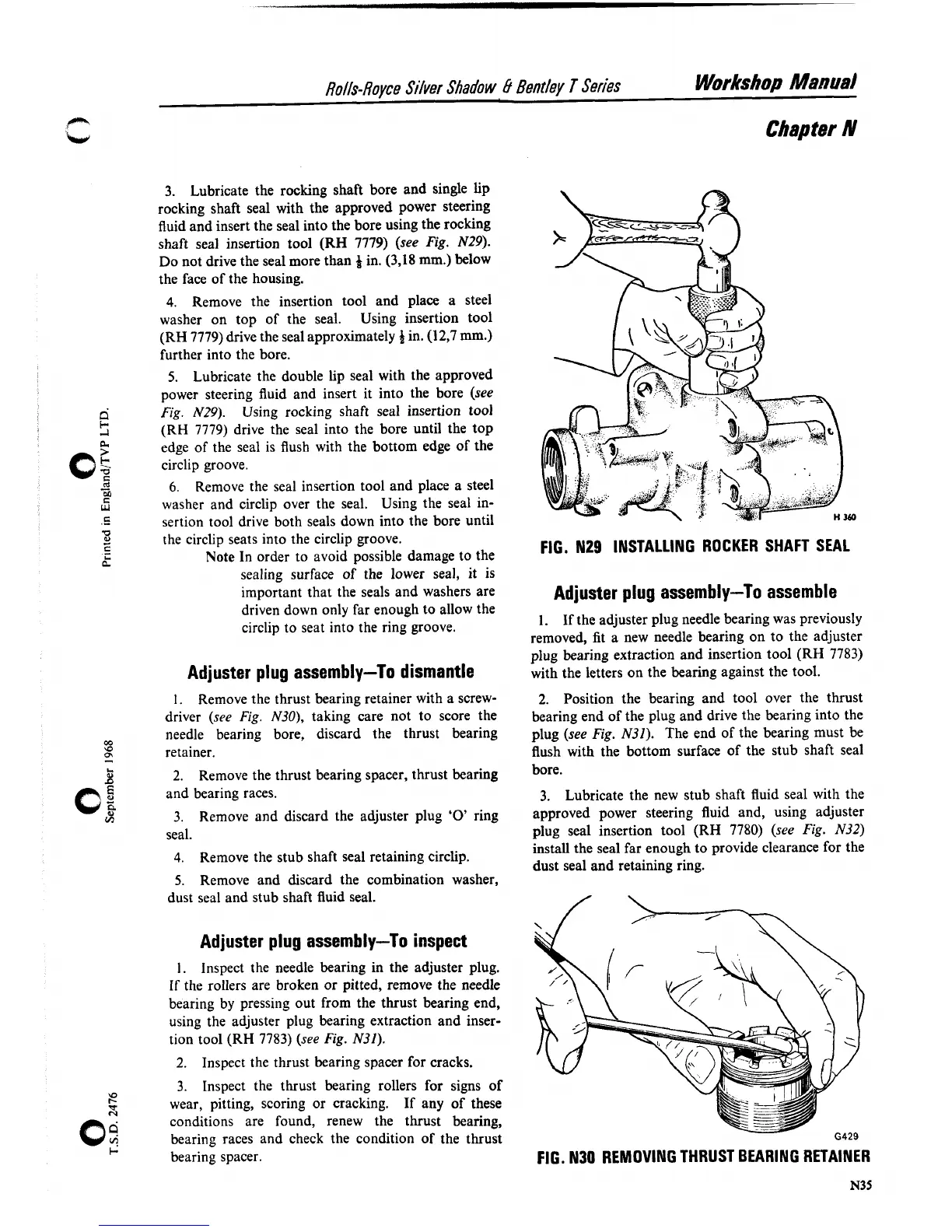

3. Lubricate the rocking shaft bore and single lip

rocking shaft seal with the approved power steering

fluid and insert the seal into the bore using the rocking

shaft seal insertion tool (RH 7779) (see

Fig.

N29).

Do not drive the seal more than

4

in. (3,18 mm.) below

the face of the housing.

4.

Remove the insertion tool and place a steel

washer on top of the seal.

Using insertion tool

(RH 7779) drive the seal approximately

f

in. (12,7 mm.)

further into the bore.

5.

Lubricate the double lip seal with the approved

power steering fluid and insert it into the bore (see

Fig.

N29). Using rocking shaft seal insertion tool

(RH 7779) drive the seal into the bore until the top

edge of the seal is flush with the bottom edge of the

circlip groove.

6.

Remove the seal insertion tool and place a steel

washer and circlip over the seal. Using the seal in-

sertion tool drive both seals down into the bore until

the circlip seats into the circlip groove.

Note In order to avoid possible damage to the

sealing surface of the lower seal, it is

important that the seals and washers are

driven down only far enough to allow the

circlip to seat into the ring groove.

Adjuster plug assembly-To dismantle

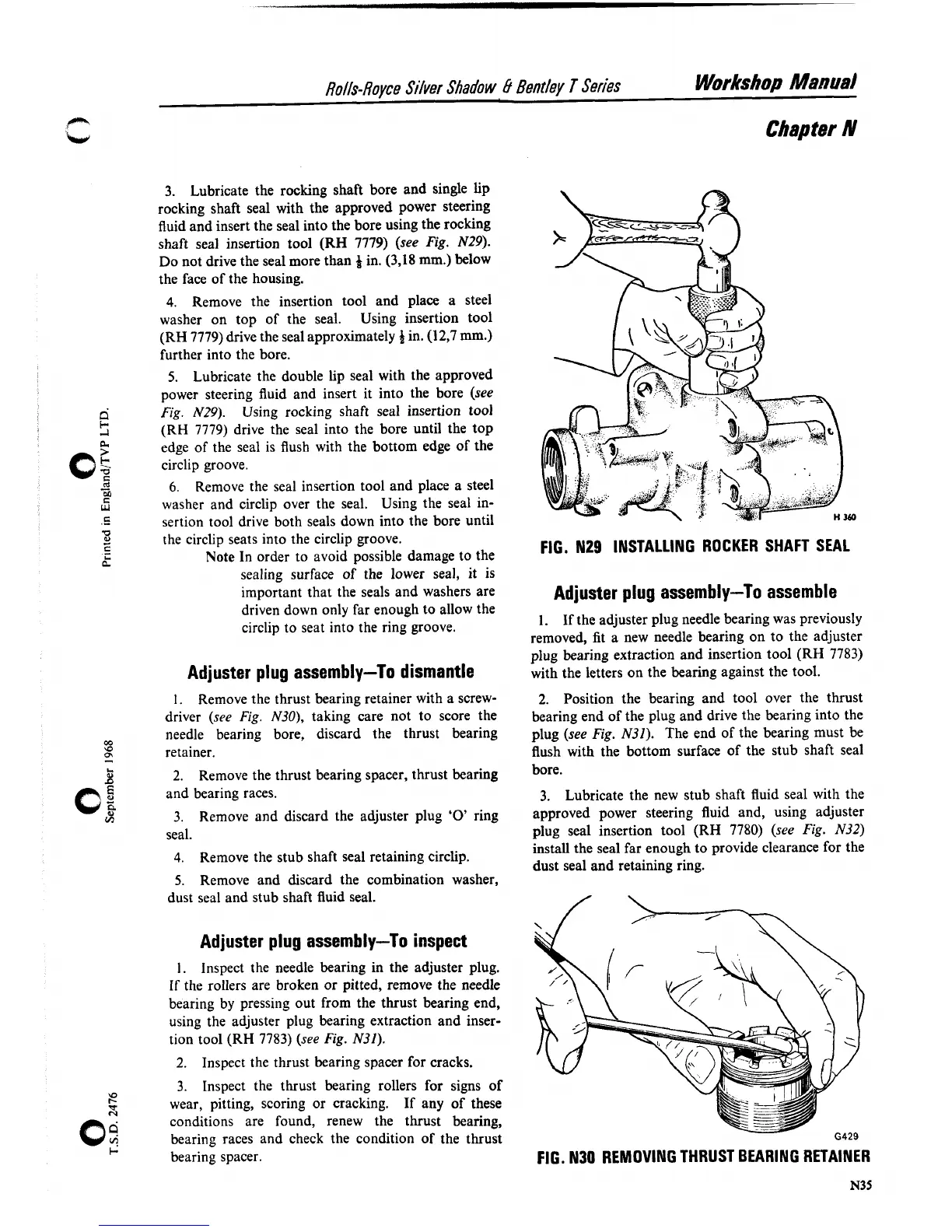

I.

Remove the thrust bearing retainer with a screw-

driver (see

Fig.

N30), taking care not to score the

needle bearing bore, discard the thrust bearing

retainer.

2.

Remove the thrust bearing spacer, thrust bearing

and bearing races.

3.

Remove and discard the adjuster plug

'0'

ring

seal.

4.

Remove the stub shaft seal retaining circlip.

5.

Remove and discard the combination washer,

dust seal and stub shaft fluid seal.

Adjuster plug assembly-To inspect

1.

Inspect the needle bearing in the adjuster plug.

If the rollers are broken or pitted, remove the needle

bearing by pressing out from the thrust bearing end,

using the adjuster plug bearing extraction and inser-

tion tool (RH 7783) (see

Fig.

N31).

2.

Inspect the thrust bearing spacer for cracks.

3.

Inspect the thrust bearing rollers for signs of

wear, pitting, scoring or cracking. If any of these

conditions are found, renew the thrust bearing,

bearing races and check the condition of the thrust

bearing spacer.

FIG. N29 INSTALLING ROCKER SHAFT SEAL

Adjuster plug assembly-To assemble

1.

If the adjuster plug needle bearing was previously

removed, fit a new needle bearing on to the adjuster

plug bearing extraction and insertion tool (RH 7783)

with the letters on the bearing against the tool.

2.

Position the bearing and tool over the thrust

bearing end of the plug and drive the bearing into the

plug (see

Fig.

N31). The end of the bearing must be

flush with the bottom surface of the stub shaft seal

bore.

3.

Lubricate the new stub shaft fluid seal with the

approved power steering fluid and, using adjuster

plug seal insertion tool (RH 7780) (see

Fig.

N32)

install the seal far enough to provide clearance for the

dust seal and retaining ring.

FIG. N30 REMOVING THRUST BEARING RETAINER

N35

Loading...

Loading...